black galvanized steel h beam universal beam steel h post h section

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

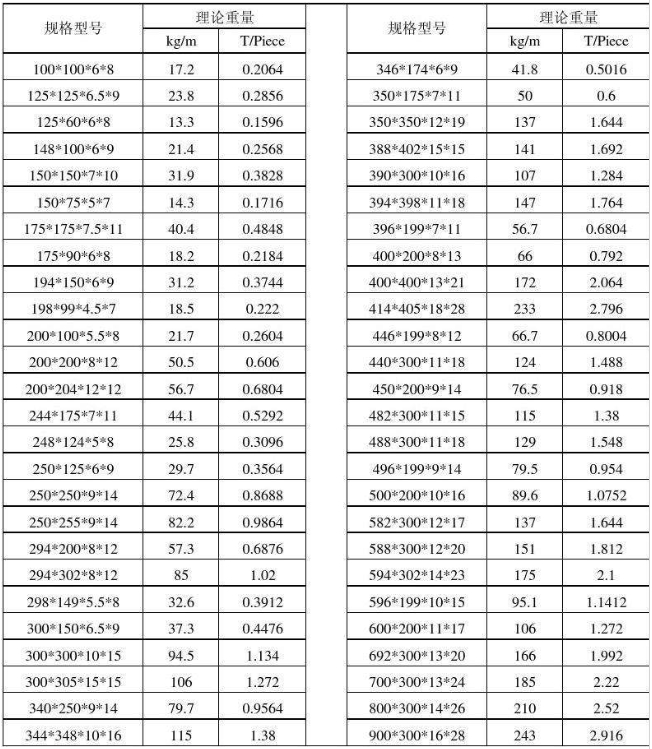

Specification

We supply ms equal & unequal angle bar, channel bar,jis channel, upn, steel i beam,h beam, ipe, ipeaa, steel sheet pile, flat bar, hollow section, tmt bar, wire rod, binding wire, wire mesh, hrc, CRC, gi coil, ppgi, roofing sheet, chequered coil & plates, medium plate, scaffolding systems, prefabricated container houses etc. Also for metal & steel processing.

If you are in the market for any steel products, please feel free to contact us.

Steel Beams are widely used throughout the construction industry when supporting heavy loads is required. Commonly termed an “I” Beam because of its shape, beams provide great load bearing support when used horizontally or standing as columns. Available in two configurations, the most popular being the Wide Flange Steel Beam aka H Beam or W Beam with non-tapered flanges. This beam shape has a wider profile for added horizontal strength, making it ideal for skyscrapers or as a house beam, along with bridge beams, trailers, platforms, etc. Standard American Beams, aka Junior Beams or S Beams, have tapered flanges for added strength when your load is concentrated on the flanges, such as machine bases, hoists, cranes or a trolley beam for your garage.

- Q: How do steel H-beams perform in structures subjected to vibration?

- Steel H-beams are known for their excellent performance in structures subjected to vibration. Their robust and rigid construction helps to minimize the effects of vibration, providing enhanced stability and structural integrity. The H-shaped cross-section of these beams ensures efficient load distribution, reducing the chance of resonance and dampening vibrations. Overall, steel H-beams are highly effective in withstanding and mitigating the impact of vibration in structures.

- Q: Are steel H-beams resistant to chemical exposure or spills?

- Steel H-beams have a general resistance to chemical exposure and spills. Steel is renowned for its durability and strength, which makes it less prone to damage from chemical substances. However, the level of resistance may vary depending on the type and concentration of the chemical involved. While steel is generally resistant to most chemicals, highly corrosive substances or prolonged exposure to certain chemicals can eventually lead to deterioration and compromise the structural integrity of the H-beams. Consequently, it is crucial to carefully consider the specific chemical environment and seek guidance from experts or manufacturers to ensure the appropriate grade of steel is selected for the intended application. In addition, proper maintenance and regular inspections are of utmost importance to detect any signs of corrosion or damage caused by chemical exposure and implement appropriate measures to mitigate potential risks.

- Q: Are steel H-beams suitable for overhead cranes?

- Yes, steel H-beams are suitable for overhead cranes. H-beams are commonly used in the construction industry due to their high strength and durability. They provide excellent load-bearing capabilities, making them ideal for supporting heavy loads, such as those encountered in overhead crane applications. The structural design of H-beams allows for optimal weight distribution and efficient load transfer, ensuring the stability and safety of the crane system. Moreover, steel H-beams can be easily fabricated and welded, making them versatile and adaptable to various crane configurations and requirements. Overall, steel H-beams are a reliable and effective choice for overhead crane construction.

- Q: Can steel H-beams be used for religious buildings?

- Yes, steel H-beams can be used for religious buildings. Steel H-beams are widely used in construction due to their strength, durability, and versatility. They provide structural support and can be used for various applications, including religious buildings such as churches, mosques, temples, or synagogues. These beams can support the weight of the roof, walls, and other architectural elements, ensuring the stability and safety of the structure. Additionally, steel H-beams can be customized and fabricated to meet the unique design requirements of religious buildings, allowing for intricate designs and flexible layouts. Therefore, steel H-beams are a suitable choice for constructing religious buildings.

- Q: Can steel H-beams be used in the construction of schools or educational buildings?

- Yes, steel H-beams can be used in the construction of schools or educational buildings. Steel H-beams are commonly used in construction due to their high strength and durability. They provide structural support and stability to buildings, making them suitable for educational facilities that require long-lasting and stable structures. Additionally, steel H-beams can be prefabricated, allowing for faster construction times and cost-effectiveness, which are important factors in educational building projects.

- Q: How do steel H-beams perform in structures with dynamic loads from machinery and equipment?

- Due to their exceptional performance and strength, steel H-beams are commonly utilized in structures that experience dynamic loads from machinery and equipment. These beams are specifically engineered to endure and distribute dynamic loads, making them a dependable choice for such applications. The H configuration of these beams provides an advantageous strength-to-weight ratio, enabling them to efficiently support dynamic loads. The flanges of the H-beams are wider than the web, enhancing their resistance to bending and torsional forces caused by machinery and equipment. Furthermore, steel H-beams possess a remarkable load-carrying capacity, guaranteeing their ability to handle the dynamic loads imposed by heavy machinery and equipment. The material properties of steel, such as its high tensile strength and durability, make it highly suitable for absorbing and dispersing the energy generated by dynamic loads. Moreover, steel H-beams exhibit excellent stiffness and rigidity, enabling them to withstand deflection and maintain their structural integrity under dynamic loads. This is crucial because excessive deflection can lead to vibrations that can negatively impact the performance and safety of machinery and equipment. Additionally, steel H-beams have an extended lifespan and require minimal maintenance, making them a cost-effective solution for structures experiencing dynamic loads. The corrosion resistance of steel ensures that the H-beams remain structurally sound even in harsh environments, further enhancing their durability. In conclusion, steel H-beams are highly appropriate for structures that encounter dynamic loads from machinery and equipment. Their advantageous strength-to-weight ratio, load-carrying capacity, stiffness, and durability enable them to effectively withstand and distribute dynamic loads.

- Q: Are steel H-beams suitable for use in the construction of transportation facilities or stations?

- Yes, steel H-beams are suitable for use in the construction of transportation facilities or stations. Steel H-beams are known for their strength, durability, and load-bearing capabilities, making them an ideal choice for supporting heavy structures such as transportation facilities. They can withstand the weight of vehicles, provide structural stability, and ensure the safety of the infrastructure. Additionally, steel H-beams are versatile and can be easily customized to meet specific design requirements, making them a reliable option for building transportation facilities or stations.

- Q: How do steel H-beams contribute to energy-efficient buildings?

- Steel H-beams play a crucial role in constructing energy-efficient buildings due to their unique structural properties and sustainability benefits. Firstly, H-beams are known for their exceptional strength-to-weight ratio, allowing for the creation of large, open spaces without the need for excessive structural support. This feature enables architects to design buildings with more natural light and better airflow, reducing the need for artificial lighting and ventilation systems and ultimately decreasing energy consumption. Moreover, steel H-beams can be fabricated to precise dimensions, ensuring accurate assembly and minimizing waste during construction. This not only saves resources but also reduces the energy required for manufacturing and transportation of materials. Additionally, steel is a highly recyclable material, making H-beams a sustainable choice for construction. The recycling process requires significantly less energy compared to producing new steel, reducing greenhouse gas emissions and conserving natural resources. Beyond their structural benefits, steel H-beams also contribute to energy efficiency through their thermal properties. Steel is a good conductor of heat, which allows for efficient transfer and distribution of thermal energy within a building. This feature enables better insulation and temperature control, reducing the reliance on heating and cooling systems and consequently reducing energy consumption. Another advantage of steel H-beams is their durability and resistance to environmental factors such as fire, earthquakes, and pests. This durability ensures the longevity of energy-efficient buildings, reducing the need for frequent repairs and replacements, which in turn saves energy and resources. In conclusion, steel H-beams contribute to energy-efficient buildings by providing a strong, lightweight, and sustainable structural solution. Their ability to create open and spacious designs, accurate fabrication, thermal efficiency, and durability all contribute to reducing energy consumption and promoting sustainability in construction.

- Q: What are the different methods of installing steel H-beams?

- Installing steel H-beams can be done using various methods, depending on the project requirements and available resources. Below are some commonly used techniques: 1. The first method involves the use of heavy machinery like cranes or forklifts to lift and position the steel H-beams. This approach is typically employed for larger structures or when installing beams at significant heights. 2. Welding is another common technique used to connect steel H-beams either to each other or to other structural elements. It requires melting and fusing the metal to create a strong joint. Welding can be carried out on-site or in a fabrication shop, depending on the project's needs. 3. Bolting is a method where bolts and nuts are used to secure the steel H-beams together or to other structural components. Bolting is often favored in situations where future disassembly or modifications may be necessary. 4. Concrete embedment is employed when additional stability and support are required. Steel H-beams are embedded in concrete by creating holes in the concrete structure and placing the beams into them. The beams are then held in place as the concrete sets. 5. Steel plates and brackets can also be utilized to connect steel H-beams to other structural elements. These plates are typically attached to the beams through bolting or welding and then affixed to the desired location. It is crucial to consider factors such as project requirements, structural design, and available resources when choosing the appropriate method for installing steel H-beams. Seeking advice from a structural engineer or construction professional is highly recommended for determining the most suitable installation approach for a specific project.

- Q: Are steel H-beams suitable for use in the construction of sports stadiums or arenas?

- Indeed, steel H-beams prove to be a suitable option for the construction of sports stadiums or arenas. Their utilization is widespread in the construction industry due to their exceptional strength, durability, and versatility. These beams offer superior structural support and have the ability to withstand heavy loads, rendering them ideal for extensive undertakings like sports stadiums or arenas. The construction of sports stadiums and arenas necessitates robust and dependable structures that can accommodate large crowds, support substantial roofs, and endure diverse weather conditions. Steel H-beams provide the requisite strength and stability to guarantee the safety and longevity of these structures. Moreover, steel H-beams can be customized to meet precise project requirements, allowing for personalized designs and efficient construction processes. They can be easily connected and assembled on-site, thereby reducing both construction time and costs. Additionally, steel represents a sustainable and recyclable material, aligning with the growing emphasis on environmentally friendly construction practices. In conclusion, steel H-beams accomplish the essential task of providing structural integrity and adaptability required for the construction of sports stadiums or arenas. Their strength, durability, and adaptability render them a fitting choice for such large-scale projects.

Send your message to us

black galvanized steel h beam universal beam steel h post h section

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products