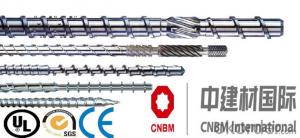

Bimetallic parallel twin screw for PVC extruder(WPC)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

Extruder/Screw And Barrel for Extruder/Plastic Extrusion

Screw Diameter 55 to 65mm

30 to 100 KG/HR

AC20 to 40HP/11.5 to 15KW

Reference Values

| CMAX series twin-screw extruder | |

| Mixing modification | PE,PP,PS+SBS,PA+EPDM,PP+NBR,NVA+silicon rubber,etc |

| PE,PA,PC,CPE+ABS(ALLOY),ABS+TPU,PBT+PET,PE+PP,etc | |

| Filling modification | PE,PP,EVA,etc+Calcium carbonate,talcum power,titanic powder, |

| ABS,PC,PS,etc+aluminum hydroxide,magnesium hydroxide,antimony oxide | |

| PP,PA,ABS+ferrous powder,sulphuric powder,ceramic powder | |

| Functional masterbatch | PP,PA,ABS,PBT,etc+burning agent and other auxiliary agents: combustion-supporting machine pellets |

| PP,PE,PS etc+starch:de-composing machine pellets | |

PE+fog-preventing dipper,stabilizer: dual-prevention machine pellets | |

| PE,EVA,ABS+carbon black:black machine pellets | |

| Colored masterbatch | PE,PP,ABS,AS,PA,EVA,PET+pigment and auxiliary |

| glass fibers/ carbon fibers reinforcement | PP,PBT,ABS,AS,PA,PC,POM,PPS,PET,etc+long fibers, small fibers,carbon fibers,crystals and so on |

| Various cables | HDPE,LDPF,LLDPE,MDPE,EVA,PVCetc+Insulating cables, coatings,PE peroxide,silicon alkyl crossing cables |

| Special materials | EVA heat-melting glue,polyurethane,fluorin rubber,fluorin plastics, PP cigarette filtering material and TPR sole material |

| Reaction extruding | Polyamide condensate,polyamide melting polymerization, polyamide polyethrne-adding,polycarbonate condensate,etc |

| Exhausting and Volatilization | Polystyrene oxide,high-absorbing resin,chlorine sulphur polyethylene |

| Powder paint | Polyester,ring oxide,lactide,polyurethane,acrylate |

Security Protection

1.coupling can effectively protect the reduction gearbox from extrusion unit overload dangers.

2.water-cooling system and lubrication systems are all real-time online monitoring.

3.drive ead pressure and melt temperature are all equipped with alarm systems.

Application

a Masterbatch

b Plastics modification

c Fiber glass reinforcement

d Cable compounds

e Alloy plastics

f Powder coating and toners, etc

Features

1. Screw components designed by computer aids is kneading type, has excellent self-cleaning function,

the new kneading block design effectively avoid the problems of overheating and energy consumption.

2. According to process system and formula requirements, the unit can optimize its L/D ratio, barrel structure, screw array,

venting number and location, feeding method, electrical control methods etc. for rational allocation.

3. Granulation system: water-cooling strand pelletizing, air-cooling die face hot cutting, water ring die face hot cutting,

Eccentric water mist hot cutting, water and underwater die face hot cutting and so on.

4. Application: Filling Modification, glass fiber (carbon fiber) enhance various kinds of master batch,

rubber and plastics compounding, plastic alloys, functional master batch, Various kinds of electric cable material,

reactive extrusion. Devolatilization process, powder coating and so on..

Advantages

The meshed structure screw has excellent mixing and plasticazation ,comparing with other type extruder.

Product show

Our machine types:

1. Co-Rotating Parallel Twin Screw Pelletizing Extruders

2. Single Screw Pelletizing Extruders

3. Die Face Cut (Air Cooling) Pelletizing Extruders

4. Double Stage / Double Degassing Recycling Extruders

5. Crushers, Mixers, Storage Tanks, Vibrators, Granulators, Blowers

6. Extruder spare parts

FAQ

PVC sheet extrusion

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: What is an extruder?

- This method of forming is continuous molding, such as pipes, plastic profiles, films and so onThe machine also has a single screw, twin-screw, multi screw points.The forming methods are single extrusion and coextrusion only.

- Q: Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q: What impact does the extruder vacuum pump open or close on the extrusion product?

- If the vacuum pump is opened, the air in the extruded product will be removed and the product material will be more closely packed. If the vacuum pump does not open, it may cause bubbles in the extruded product.

- Q: Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- Setting the temperature completely depends on the actual situation.Generally, the position of the leaky hopper is lower than the temperature of the extruder barrel and the die head

- Q: PLC based extrusion machine control system design graduation thesis and PLC based injection molding machine control system thesis content?

- Tip three: select the topic according to the documents. Literature is the foundation of support, enrich the direction and point of view, but also can reflect the research result, the author embarks from the existing literature, topic and refine the title, became the third skills.

- Q: Why single screw extruder is controlled by high school and low?

- What is controlled by high school? I can't answer the question without saying it

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q: Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- How big is it? Not too big. I suggest using a 40 or 30 too big block. You have to use a special break knot. There is a kind of broken engineering material. I wonder if you can find it

Send your message to us

Bimetallic parallel twin screw for PVC extruder(WPC)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords