Parallel Twin Screw Extruder For Plastic CMAX-5000

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

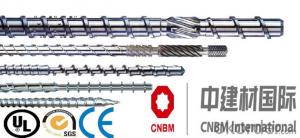

Extruder/Screw And Barrel for Extruder/Plastic Extrusion

Screw Diameter 55 to 65mm

30 to 100 KG/HR

AC20 to 40HP/11.5 to 15KW

Technical parament

| model | CMAX-20 | CMAX-30 | CMAX-50 | CMAX-65 | CMAX-72 | CMAX-92 |

| Screw Dia.(mm) | 21.7 | 30 | 50.5 | 62.4 | 71.2 | 91 |

| Rotate.speed(r/min) | 600 | 400 | 400/600 | 500/600 | 400/500 | 400/500 |

| Main Motor(kw) | 4 | 11 | 11/15 | 55/75 | 90/110 | 220/250 |

| L/D | 32-40 | 28-48 | 28-48 | 28-48 | 28-48 | 28-40 |

| Output(kg/h) | 2-10 | 5-30 | 40-80 | 100-300 | 300-600 | 600-1000 |

Application

CMAX series parallel twin screw extruder is widely used for plastic modified granulation ,wood plastic composite granulation ,PVC granulation,PET granulation ect.

Features

It is mainly composed of high torque gearbox,meshed structure screw ,blending feeding system,exhaust system ,heating and cooling system ect.

Advantages

The meshed structure screw has excellent mixing and plasticazation ,comparing with other type extruder.

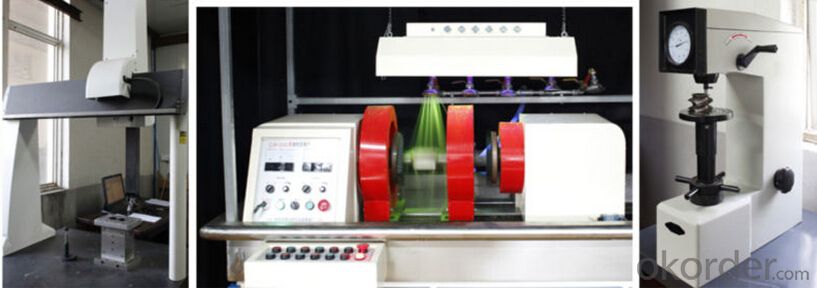

Product show

FAQ

PVC sheet extrusion

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Cable extruder type 657090 machine, describes the diameter of the screw, the unit is mm.The greater the number, the greater the equipment, the greater the amount of gumIt is usually marked on the control cabinet of the equipment

- Q: Produce 10 square wires with the smallest extruder

- If the production of single core line, then 50 machines can also do, but low efficiency, unstable line,.70 or 90 machine idealIf it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: What are the common extrusion molding products?

- Extrusion molding products are as follows:1 、 plastic pipe, for example: water pipe up and down;2, plastic profiles, such as: doors and windows, plastic steel profiles.3, plastic plates, such as: wood plastic doors, plastic doors,4, plastic sheet (sheet and board is the difference between the thickness, thin, thick plate), such as: mobile phone membrane.

- Q: Can PC and PP be extruded together with two materials in an extruder?

- No co extrusion, PC polycarbonate, PP polypropylene, two kinds of product structure is not the same, not the same chemical composition, viscosity and liquidity is not the same, processing temperature and processing technology is also very different, and two kinds of products, so not incompatible, CO extrusion.

- Q: Why do screw extruders often extrude light red plastic products?

- You should have before the production of red raw material hopper or hopper and barrel, or between the screw shank and barrel etc. the raw material residue, not clean, often with extrusion part.

- Q: Comparison of injection molding machines and Extruders

- The plastic to replace steel or nonferrous metal, plastic cement, which is widely used in agriculture, building materials, packaging, machinery, electronics, automobiles, household appliances, petrochemical and defense, extruder and daily life other fields. So it can be predicted that in twenty-first Century, the plastic will be one of the most important raw material of human activities. The extruder design due to extrusion molding is the main form of plastic processing, so the development of plastic extrusion molding technology and equipment has important significance. The polymer materials used in blending type mixing equipment modification there are three main types: parallelwith twin-screw extruder, reciprocating screw kneader and series disc extruder. The small corotating twin screw extruder has domestic production can squeeze But tons of large mixing extrusion granulation unit will rely on the import machine technology. At the same time. Reciprocating screw kneader and series disc extruder is a necessary device for preparing high fill and high added value of polymer alloy, the current domestic research on them is just in the prototype stage, specifications, varieties not all, have broad prospects for development.

- Q: What should be paid attention to in the daily maintenance of the extruder?

- Attachment(1) inspect the rolling barrel, vibrating screen, motor and so on, and leak out the sealing parts.(2) cooling equipment and piping are clean and clean, and there is no suspended impurity in industrial soft water. Water filters and water tanks should be regularly checked, cleaned, kept clean and replaced with new water.

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat,

- Q: Is the extruder the same as the extruder?

- A large number of continuous production, such as tube, rod, profile, also can be used for plastic modification and granulation.The scope of the application is different, but the meaning is similar, reference material, China, extruder, trading network

- Q: Now I want to do it How to change the equipment, please help tell your heroes ah!Used to do PVC pinch plate, now changed to PVC threading tube

- If you want to change, it is best to find the original purchase of equipment manufacturers, so that they change for you.

Send your message to us

Parallel Twin Screw Extruder For Plastic CMAX-5000

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords