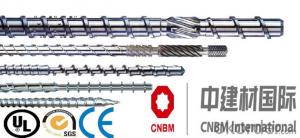

Parallel Twin Screw and Barrel For Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 1500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

conical twin screw barrels for PVC pipe&profile&WPC extruding machine

Product Description

Material

High quality alloy-steel

1) 38CrMoAlA(JIS SACM645)

2) 42CrMo(JIS SCM440)

3) 9Cr18Mov

4) CW6Mo5Cr4V2

Heat-treatment

Nitriding treatment

Electroplated hard-chrome finish

Spray bimetallic coating

our service

In today’s competitive market, making a PVC or other extruder product at maximum productivity levels and the lowest possible cost is paramount in growing your business, increasing profits and meeting your overall business objectives.

For over one decades CNBM has been a leading supplier in machine components for the Plastic, Food and Rubber industry. Flite Technology has earned the reputation as an innovator and industry leader in the manufacturing of precision single and twin feed screws and barrels. Whether it's new, rebuilding, designing or repair, you can be confident our service, quality and performance will be unsurpassed.

We also offer very aggressive competitive pricing. Pick up and delivery service is available as well as reverse engineering for existing worn out parts.

We are focus on service for solution, not only supply screw barrel.

We can do any kind of screw barrel for extruder molding machine, injection molding machine and blow molding machine, see the application as below

FAQ

screw barrel

1.Q: How about CNBM?

R:CNBMChina National Building Materials Group Corporation)(Fortune Global 500 companies)is a state-owned CNBM is state owned largest building materials and equipment manufacturer and supplier, we have more than more than 500 factories.

2. Q:What's CNBM capacity

R:Passed ISO 9001:2008, Our workshop 12000SQM, thousands good experienced employee, All CNC computer control screw processing, 1000sets screw barrel capacity per month.

3. Q:What's the delivery time

R:for regular size, we have finished stock and semi-finished stock, 2weeks max enough

for customized, normally 3~4weeks.

4.Q:How about CNBM screw barrel quality and price

R:Germany Technical invested, top quality in China with competitive price and engineers available to service machinery overseas after-sale service

5. Q:How to make sure the screw suitable for my extruder?

R:Let's know what size you want and we can check it with our drawing. If your extruder is made in China,it's easy to get the original drawing.

6. Q:what's the life time and guarantee buy from CNBM screw barrel?

R:3~5years life time for nitriding ones and bimtallic ones will be longer One year min. Guarantee

7.Q:How to contact with you

R:just reply to me below if have any question.

Company Information

CNBM International Corporation

(CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.With the advantages in Cement, Composite Materials, New Building Materials and Engineering, We are enlarging sub-brand. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. In line with the business, CNBM International launched E-business platform Okorder.com. It conformed the best resource and logistics to meet the customers’ request with 24 hours full-time service.

Our Vision: Initiate new global trading structure; create new value for benefit related partners.

We will do utmost to promote rational use of resources under the new structure, meanwhile, create new value of “green, environment friendly and sustainable’ for a more prosperous future.

CNBM International Co. Carpet Dept.

At CNBM International Co. Carpet Dept., we design and weave beautiful carpets of superb durability - with axminster, tufted and wilton carpets to suit all hospitality environments. · There is no size limitation on rug size. Rugs can be created with a variety of materials from pure wool to woolen silk, from natural fiber to chemical fiber.

- Q: What is the adjustment method of China's extrusion machine die?

- (2) run mode: plastic glue on the plasticizing after adjustment for mold screw, die according to how much glue circle, ran glue, side adjustment, adjustment should be loose thin screws, tighten the screws run glue thick; at the same time sampling check plastic thickness is eccentric, until evenly so far, then tighten the screw die respectively.

- Q: Extrusion blow molding machine, storage or continuous type good?

- The amount of extrusion must be continuous, efficient, and wasteful

- Q: Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q: Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- 1. injection molding2., the structure is relatively complex, high appearance requirements. Extrusion does not meet requirements3. most are: ABS, ABS+PC, PP and so on4., according to color requirements granulation - drying particles - filling the mold ---- debugging injection molding machine ---- injection molding production - after the selection of finished packaging (if silk screen requirements, but also the need for silk screen)

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- See section - cross section. Setting adjustment with RPC

- Q: Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- There is a kind of broken engineering material. I wonder if you can find it

- Q: Now I want to do it How to change the equipment, please help tell your heroes ah!Used to do PVC pinch plate, now changed to PVC threading tube

- If you want to change, it is best to find the original purchase of equipment manufacturers, so that they change for you.

- Q: What are the components of an extruder?

- The driving system of an extruder is to drive the screw, providing the torque and speed required by the screw in the extrusion process, usually consisting of an electric motor, a reducer, and a bearing.3. heating and cooling device for extruderHeating and cooling are necessary conditions for the process of making a plastic extruder. It includes two aspects:(1) now host extruder is usually divided into electric heating, resistance heating and induction heating, heating installed in the fuselage, neck, head of each part. The heating device heats the plastic in the outer barrel to increase the temperature required for the process operation.(2) the cooling device is designed to ensure that the plastic is in the temperature range required by the process. Specifically, to eliminate the excess heat generated by the shear friction of the screw rotation, in order to avoid the temperature is too high, so that plastic decomposition, coke burning or stereotypes difficult. Cylinder cooling water cooling and air cooling is divided into two kinds, small and medium sized extrusion machine adopts air cooling is more appropriate, large use more water or two kinds of combined cooling; cooling water cooling screw mainly adopts the center, the purpose is to increase the solids conveying rate, stable glue volume, and improve product quality; but in the cooling hopper one is, in order to strengthen transport of solid material, prevent warming plastic sticky jam outlet, two is to ensure the normal work of the transmission part.

- Q: Does anyone know the operating procedures for the cable 65+120 extruder?

- Operating procedures are based on the preparation of equipment instructions, you can increase some of the preparatory work before the boot, the middle is the operation of equipment instructions, and finally must have safe and civilized operation instructions!

Send your message to us

Parallel Twin Screw and Barrel For Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 1500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords