Bidim Geotextile Non Woven Needle Punch Geotextiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Geotextile

Good flexibility, permeability, filtration, sepatation and easy for construction.

Product Application

CMAX Geotextile has excellent permeability, acquired, durablity, which can be widely used in railway, highway, movement hall, dams, hydraulic structures, hence hole, coastal shoal,reclamation, environmental protection and other projects.

The main products are Synthetic staple fibers needlepunched non woven geotextiles and slit and split film yarn woven geotextiles.

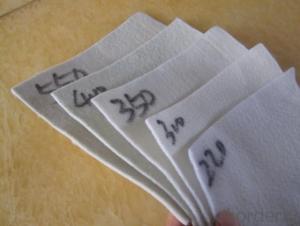

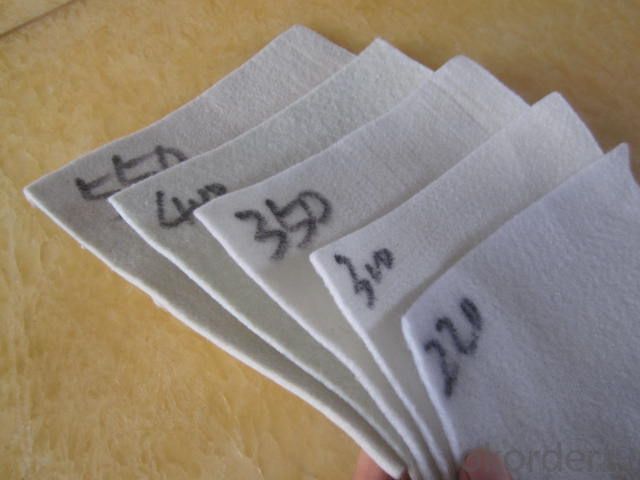

Product Specifications:

Weight: 100GSM-1500GSM

length: 50m-100m

width:1m-8m

material:100%PET

Packaging Details:pp woven bags or at your request

Delivery Detail:15 days

Product Property:

1. Super high strength, ultralight, high resistance.

2. Resistance to chemical erosion, excellent water resistance.

3. Abrasion resistant.

4. Excellent anti-aging and anti-UV property, good weather fastness.

FAQ:

Q: What kind of payments could you support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Design of interlocking turf slope protection brick directly on the geotextile, river earth side by 1: 2.5 slope excavation, began laying geotextile, grass sand and gravel, can lay it? Geotextile laying on the grassroots what are the requirements? More

- No special requirements, mainly from the role of filtering, over the water, but I, specializing in the production of geotextile, geomembrane, wish smooth

- Q: Can geotextiles be used for separation of different soil layers?

- Yes, geotextiles can be used for the separation of different soil layers. Geotextiles are commonly used in civil engineering and construction projects to create a barrier between different soil types or layers. They help prevent the mixing and migration of soil particles, improving the overall stability and performance of the soil structure.

- Q: Are geotextiles resistant to acid degradation?

- Yes, geotextiles are generally resistant to acid degradation. They are designed to withstand various environmental conditions, including exposure to acids, making them suitable for applications where acid resistance is required.

- Q: Roof garden pool at the bottom with pebbles, pebbles above with geotextile, geotextile above the soil

- Geotextile laying on the soil can be, goose soft stone has replaced the effectiveness of the drainage board. Geotextile play a filtering effect, the excess water through the cloth, go through goose soft stone flow. Soil is geotextile interception, will not be lost, plug the drain, Huazhi geotextile material manufacturers.

- Q: What are the environmental impacts of geotextile production?

- The environmental impacts of geotextile production include energy consumption during manufacturing, emissions of greenhouse gases, water and air pollution from chemical processes, and the generation of solid waste. However, compared to traditional construction materials, geotextiles have lower environmental impacts in terms of resource consumption, carbon emissions, and waste generation.

- Q: Can geotextiles be used in shoreline erosion control projects?

- Yes, geotextiles can be effectively used in shoreline erosion control projects. Geotextiles are permeable fabrics that can be installed along shorelines to stabilize the soil and prevent erosion caused by waves and currents. They can be used as a layer to separate the soil from the water, allowing for water filtration while reducing soil erosion.

- Q: How to judge the geotextile test results are reliable

- Determine whether the tensile test results of the material are reliable, depending on whether the tensile process of the material to be tested during the test has reached the state required by this detection method. As a tensile test, to test the tensile strength and elongation of the material under specified conditions. Stretching process, the material to be tested to be uniform force, the test machine fixture holding the sample to be solid, the sample does not produce slip nor be caught damage. This is the test process of the requirements of the test machine fixture and the installation of the sample requirements, only to meet this requirement and other requirements, the test results may be accurate. Geotechnical composite materials - Geosynthetics - Staple acupuncture non - woven geotextiles GB / T-1998 Geosynthetics - Filament spunbonded acupuncture non - woven geotextiles GB / T - 1998 Geosynthetics Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetics - Geosynthetic materials GB / T - 1998 Geosynthetics - Geological synthetic materials Polyvinyl chloride geomembrane GB / T-1999 Geosynthetics Plastic geogrid GB / T-1999 Geosynthetics Plastic flat wire braided geotextiles GB / T-2002 Geosynthetics Plastics 3D geogrids GB / T-2002 geosynthetics / outer composite geotextile

- Q: What are the different geotextile installation techniques in reinforcement?

- There are several geotextile installation techniques used in reinforcement, including direct placement, sandwich method, and wrap-around method. In direct placement, the geotextile is laid directly on the soil or subgrade and then covered with additional soil or aggregate. The sandwich method involves placing the geotextile between two layers of soil or aggregate, creating a reinforced layer. The wrap-around method involves wrapping the geotextile around a structure, such as a retaining wall or pipe, to provide additional support and stability. These installation techniques help improve the strength and performance of soil structures in various engineering applications.

- Q: What are the different factors affecting the durability of geotextiles?

- There are several factors that can affect the durability of geotextiles. Some of the key factors include UV exposure, chemical exposure, moisture, temperature variations, mechanical stress, and installation techniques. UV exposure can cause degradation of the geotextile material over time, while chemical exposure can lead to chemical reactions that weaken the fabric. Moisture can also play a role in degrading the material, particularly if it leads to mold or mildew growth. Temperature variations can cause expansion and contraction of the fabric, which can lead to wear and tear. Additionally, mechanical stress from factors such as heavy loads or friction can impact the durability of geotextiles. Finally, improper installation techniques, such as inadequate anchoring or tensioning, can also affect the longevity of geotextiles.

- Q: Are geotextiles suitable for use in geocell retaining walls?

- Yes, geotextiles are suitable for use in geocell retaining walls. Geotextiles are often used as a separation and filtration layer in geocell systems, helping to prevent soil erosion, improve drainage, and enhance overall stability of the retaining wall.

Send your message to us

Bidim Geotextile Non Woven Needle Punch Geotextiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords