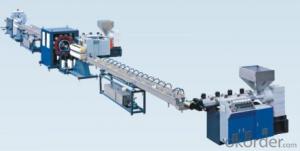

PC Lamp Light LED Tube Profile Making Machine Extrusion Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PC Lamp Light LED Tube Profile Making Machine Extrusion Production Line

Our company in PC lamp extrusion production line with many years of experience, has been general customers approval.

This production line is mainly used to produce PC fluorescent tubes, LED lamp (LED fluorescent tubes), PC tube, transparent double-color tube, grind arenaceous pipe and fluorescent lamp categories include smooth, double-color, grinding, sandblasting, light diffusion, semicircle, etc.

PC tubes chimney as long as used to manufacture LED energy-saving lamps, LED energy-saving lamps due to its privileged energy-saving effect, more and more get the market approbate, such as the ordinary sunlight 40 w light intensity, LED lamp only need 12w can achieve the same intensity, Moreover LED fluorescent lamp of long service life, and does not have mercury pollution.

Pc tube extrusion production line is mainly composed of chimney profiles extrusion host, 3d electric calibrating bench, belt gauzing machine, cutting machine, feeder components. Extrusion host adopt efficient extrusion screw, variable-frequency regulating speed technology, on the basis of various specifications of product configuration of different specification host, Calibrating bench adopt stainless steel wet pan, match domestic brands vacuum pump. Drawer adopts Siemens motor, frequency conversion control, manual or automatic electric lift, belt traction, Cutting machine adopts imported sawblade positioning cut off.

The whole production line includes the following parts:

1. Drying machine

2. SJ-45 single screw extruder

4. profile molds (make according to your requirements)

5. Vacuum cooling shaping table

6. Belt type tractor

8. Precise Cutting machine

9. Automatic Stacker

Advantage and application:

1. Automatic cutting machine, cutting process with synchronized traction,Cutting length of by laser positioning, automatic/manual/timer/counter/reminder,.Online cutting length error in (0.20mm)

2. The Extruder has frequency converter to save energy power/ Electricity

PC Profiles production line

Raw material granulator → Drying Machine → Extruder→ Vacuum Cooling Shape Table → Belt type double motor Drawing machine →Film device →Cutting Machine → Stacking Rack(final products)

The main technical parameters | |||||

Model | SJ-45 | SJ-55 | SJ-65 | SJ-80 | SJ-90 |

Screw diameter(mm) | φ45 | φ55 | φ65 | φ80 | φ90 |

Center Hight(mm) | 1000 | 1000 | 1000 | 1000 | 1000 |

Production capacity (kg/h) | 45 | 70 | 100 | 150 | 180 |

Screw Rotational Speed(r/min) | 90 | 90 | 90 | 90 | 90 |

Main Power(kw/h) | 11 | 15 | 22 | 30 | 45 |

Heater ouan | 2+2 | 3+2 | 4+3 | 4+3 | 4+4 |

Total installed capacity(kw) | 18 | 25 | 38 | 50 | 70 |

Weight(t) | 1 | 1.2 | 1.5 | 1.8 | 2.2 |

- Q: Consult, small toys, plastic products how to shine? What kind of machine or what kind of abrasives do you need? The swordsman knows to ask for help, if feasible, and to have a heavy score! This toy is made of diamond! It's about three or four centimeters in size! Urgent!

- One is to start from the mold and make the inner surface of the mold smooth!One is starting from the material, to make high light products, first of all, there must be good raw materials, and secondly, to have a good stain, high light color powder, to achieve free spraying, high light injection molding, first of all need to use high gloss plastic material.

- Q: What are the standard tolerances for engineering plastic products machined (e.g. lathes, milling machines)?

- No, look at the drawings, requirements, no note tolerances, drawings should be marked, and if there is no mark, then there is a problem with drawings. Drawing requires that all elements be annotated.

- Q: How much does it cost to run a small waste plastics processing plant?

- Hello, you need to tell me in which city and set up factories in general a small waste plastic particles Factory granulation machine and rolling machine related maintenance tools almost one hundred and twenty thousand or so this is the lowest level for the continuous operation of the workers to four hundred pounds or twenty total count down several flat covering but the mechanical and artificial need not one hundred and eighty thousand factory covers an area of such the words of small plastic granulation plant can take 25

- Q: What is the function of adding filler in the processing of plastic products?

- Physical properties change has come under the situation, but also can reduce the cost

- Q: Do waste plastics recycling processing, the state subsidies, and now the prospects are good?

- Moreover, the after-sale service of the manufacturer is very good. So it works very well. I recommend you to Shandong Qufu (Confucius's hometown) to look at the side of field visit, actually there's a purchase as clear as noonday, Shengxin machinery Bao Aiqing is the manager of a professional, give you a ball 897026688 and ask what questions or ask professional better.

- Q: What kind of equipment do you need and how much will it cost to invest?

- Networking is the premise, at 21:28 on August 18, 2013, 57 seconds

- Q: What method or machine do you want to throw bright?

- Some plastic products come out very smooth, not in plastic polishing, polishing on the mold

- Q: How is the processing cost of plastic parts calculated? Would you please tell me how to calculate the processing cost of plastic parts? For example, how is the processing fee formed?

- Note: manufacturing costs include the following:Labor costs, wages and insurance paid for them.Manufacturing costs include the costs of workshop production, the necessary tools, tools, equipment, supplies, and power and energy costs of the workshop.Administrative expenses, expenses arising from management.Production cost: mainly refers to material costs.

- Q: Benefits of plastic products

- The most lightweight plastic, chemical stability, will not rust; the good impact resistance; the transparent and has good wear resistance; the good insulation, low thermal conductivity; the general molding, coloring is good, the processing cost is low; most heat-resistant plastic, thermal expansion. Easy burning; poor dimensional stability, easy deformation; majority of poor low temperature resistant plastic, low temperature brittle; easy to aging; some of the plastic soluble in solvents.

- Q: How do we calculate the cost?

- Four major matters needing attention in investment of recycled plasticsPlastic recycling is a sunrise industry, the country, not only the effective utilization of resources and protect the environment, reduce the white pollution, from 2004 recycled plastics market, considerable benefits, as a new way of friends, is the author contact situation (editor's note), there are many aspects should be prepared in the first period, not to fight the battle without. The main problems are concentrated in the following aspects:1, blind follow-upAccording to the renewable materials market in 2004 prices, had been recycled most of the people have a better income, as for friends, in the test stage, on the surface has the advantages of simple process, low equipment investment, the product basically in short supply, technology content is not high, ordinary people can do at the same time, the raw material is us around the most familiar things, everywhere, everywhere can buy. Rough calculation, such as waste 2000 yuan can receive, the product can sell 4000 yuan, absolutely profitable.

Send your message to us

PC Lamp Light LED Tube Profile Making Machine Extrusion Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords