Automatic Blow Moulding Machine for LED PC Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Blow Moulding Machine for LED PC Cap

LED PC Cap Automatic Blow Moulding Machine Production Line Feature:

Reasonable equipment design, compact construction, simple operation

Equipment with high degree automatic, cost less expenses

Electrical equipment, Hydraulic system, Seal parts and Lubrication system adopt the components of famous factory in the world, with low failure rate.

To achieve the best quality guarantee, no matter the appearance and internal, automaticblow moulding machine rate of quality goods is above 99%.

LED PC Cap Automatic Blow Moulding Machine Technical Characteristic:

LED PC Cap Automatic Blow Moulding Machine adopt European technology, control the hydraulic system with pressure and flow double proportion. The speed of pressure can adjust nonpolarly, high stability, exchange control the electrical system with man-machine interface. Operating surface has a machinery safety configuration, two electrical safety configuration to ensure the safety of operators.

PLC+touch screen, making the operation easy. Automatic malfunction alarm with selfdiagnosis, making the malfunction clear at a glance.

Center input die head, eliminating the knit line completely and making it easy to change the material and color.

Double linear rolling motion guider in moving, opening and closing mold, making the clamping force equally distributed, so the cut is smoother.

Control the hydraulic system with imported proportional valve, ensuring the action steady, accurate and energy saving.

High speed and efficient plasticizing system, mixing well and ensuring the produce purity.

LED PC Cap Automatic Blow Moulding Machine Parameter:

Specifications | Unit | Parameters |

Max container capacity | L | 20 |

Extruder System |

|

|

Screw Diameter | mm | 82 |

Screw L/D ratio | L/D | 30:1 |

Screw Speed | rev. / min. | 10~50 |

Plasticizing Capacity | Seconds/die. | 60 |

Number of heating zone barrel | zone | 5 |

Extruder driving Power of barrel | KW | 34 |

Max Injection quantity | L | 1.5 |

Die Head |

|

|

Max die diameter | mm | 130 |

Number of heating zone | zone | 4 |

Extruder driving power | KW | 8.7 |

Clamping Device |

|

|

Platen Size(WxH) | mm | 440 x 600 |

Platen opening stroke | mm | 330~780 |

Clamping force | KN | 210 |

Next blowing Device |

|

|

Blowing the head off and landing trip | mm | 120 |

Manual control Blowing the head off and landing trip | mm | 80 |

Manipulator |

|

|

Take pieces of travel | mm | 1000 |

Framework |

|

|

Lift travel | mm | 250 |

Hydraulic System |

|

|

Rated pressure of big pump | Mpa | 14 |

Rated flow of big pump | L/min | 180 |

Motor power of Hydraulic pumps | KW | 45 |

Parison Controlling Of Hydraulic Servo System |

|

|

Rated pressure | Mpa | 6 |

Rated Flow | L/min | 22 |

Motor power of Hydraulic pumps | KW | 4 |

Pneumatical System |

|

|

Air source pressure | Mpa | 1 |

Working pressure | Mpa | 0.8 |

Air consumption | M3 / min. | 0.6 |

Electrical Control System |

|

|

Water Supply |

|

|

Water supply pressure | Mpa | 0.3 |

Power Supply | ||

Voltage | V | AC380V±10% |

Frequency | HZ | 50 |

Wire |

| 3Phase |

Total of rated power | KW | 91.7 |

Average power consumption | KW.h | 45 |

Total weight | Ton | 11 |

Dimension of machine (Lx W x H) | m | 5.3×2.7×4.5 |

LED PC Cap Automatic Blow Moulding Machine Parts Picture:

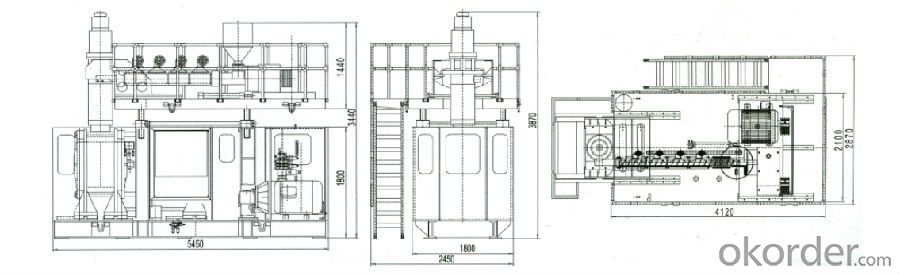

LED PC Cap Automatic Blow Moulding Machine Drawing Picture:

LED PC Cap Automatic Blow Moulding Machine Electrical Parts Photo:

LED PC Cap Automatic Blow Moulding Machine Products Photo:

- Q: Which is more practical, plate pressure type oil filter and multi-function oil purifier? What are their advantages and disadvantages?

- For example: DYJ series multifunctional lubricating oil purifier Chongqing Wanmei according to the characteristics of various types of oil kinematic viscosity, flash point index difference, a common type of specialized development and production of multifunctional lubricating oil purifier, suitable for lubricating oil of various types, different grades of effective purification. Is the industrial and mining enterprises to purify all kinds of lubricating oil ideal equipment. The two-stage or multi-stage vacuum purifier is more efficient.Use:Widely used in hydraulic oil, hydraulic transmission oil, gear oil, gasoline engine oil, diesel engine oil, compressor oil, refrigerator oil, heat treatment oil and so on. The utility model can rapidly remove moisture, gas and mechanical impurities in oil, flash out the light acid and light hydrocarbon, improve the quality of the oil, and restore the use performance of the lubricating oil. Ensure the normal operation of power system, hydraulic system and lubrication system.

- Q: What is the working principle of the vacuum oil filter?It's easy to understand

- The gasification temperature of oil and water is different. Working in a vacuum can improve efficiency and control temperature to remove moisture in the oil

- Q: What is the effect of the oil filter on the filtration of fine particles?

- The filter on the market are the theoretical precision, must understand the actual filtration precision filter, different oil should choose corresponding filter, industrial oil and edible oil, medical liquid filtration in the filter selection should pay special attention to the material composition matching filter

- Q: Under what conditions does the air pressure oil filter fail to clean oil?

- How do you say this? For example, the filter element, the filter element is used, right?

- Q: How often do you change the oil filter when the turbine is in oil?

- Mainly depends on your good quality of oil to determine. Generally, when the small post of the filter net comes out, it proves that the filter paper should be changed.

- Q: Transformer oil filter how to choose?

- We must remember that ultra-high voltage transformer oil for 500KV ultra high voltage transformer and a similar demand for electrical power equipment for insulation and cooling medium, oil detection by SH0040-91 industry standards, test items include appearance, color, density (20 degrees Celsius), viscosity, aniline point, freezing point, pour point, flash point, and value, corrosive sulfur, water soluble acid and alkali, oxidation stability (precipitation, acid), breakdown voltage, dielectric loss factor (90 degrees Celsius), interfacial tension, trace water, condensate gas ratio dispersion. Hope to help

- Q: Common troubles of vacuum oil filter

- 5, the sealing gas leak at each connection;6, wearing parts of vacuum pumps. 1, is a normal phenomenon, you need to filter many times;2, it is normal to raise the temperature of the oil, so that the water evaporates;3. Increase the vacuum pump;4, need to replace the new oil;5, inspection and maintenance;6. Replace the wearing parts. Under normal working conditions

- Q: What kind of scheme is better for the oil filter except the impurity?

- 4, vacuum oil filter, the principle is to use the principle of vacuum removal of water in the oil, the use of fine filter cartridge to remove impurities in the oil. The utility model has the advantages of good water removing effect, good impurity removing effect, stable operation of the system and no need for human care. Before now, the oil filter is basically one of the best. However, the selection of such oil filter equipment, there is a great deal of attention. Because the capacity of vacuum water removal is affected by the area of the vacuum separator in the oil filter. Theoretically, the greater the area of the vacuum separator, the better the effect of water removal, but because of the limited size of the equipment, so the vacuum separator will not continue indefinitely. So the chance of high quality vacuum oil filter in the vacuum separator, vacuum separation device in the Lv of the same area, who use the high technology (equivalent to the increase of vacuum separator area), oil filter whose effect will be better. This is also the choice

- Q: How to choose the proper plate and frame pressure filter

- Plate and frame pressure type oil filter is usually thousands of dollars, the size of the model may be tens of thousands, the size of the model according to the filter needs to determine. The bigger the oil pump, filter plate, filter paper area and so on, the higher the price.

- Q: Operating principle and characteristics of electrostatic oil filter

- Reduce equipment failure, reduce downtime, save the maintenance cost A. to extend the service life reduce replacement costs 44.7% B. to prevent downtime losses caused by 22.3% C. 19.4% D. to reduce the equipment investment and reduce friction parts, energy saving 5.5% E. enhance the production efficiency of the economic benefits of 4.1% F. to reduce labor costs 2% g. lubrication to reduce oil consumption 2% three, greatly extend the life span of oil (5 ~ 7), reduce the oil yield (80% ~ 90%), protect the environment. Four 、 with perfect automatic protection device, unmanned operation can be carried out continuously, the maintenance cost is low, and the economic effect is the best.Electrostatic oil filter processing efficiency is too low, the speed of processing oil is very slow, while the effect of micro filtration of water is not good, it depends on what you filter oil, which contains impurities

Send your message to us

Automatic Blow Moulding Machine for LED PC Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords