Automatic Blow Molding Machine for 5 Gallon PC Bucket

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Blow Molding Machine for 5 Gallon PC Bucket

5 Gallon PC Bucket Automatic Blow Molding Machine Production Line Feature:

Reasonable equipment design, compact construction, simple operation

Equipment with high degree automatic, cost less expenses

Electrical equipment, Hydraulic system, Seal parts and Lubrication system adopt the components of famous factory in the world, with low failure rate.

To achieve the best quality guarantee, no matter the appearance and internal, automaticblow molding machine rate of quality goods is above 99%.

5 Gallon PC Bucket Automatic Blow Molding Machine Technical Characteristic:

5 Gallon PC Bucket Automatic Blow Molding Machine adopt European technology, control the hydraulic system with pressure and flow double proportion. The speed of pressure can adjust nonpolarly, high stability, exchange control the electrical system with man-machine interface. Operating surface has a machinery safety configuration, two electrical safety configuration to ensure the safety of operators.

PLC+touch screen, making the operation easy. Automatic malfunction alarm with selfdiagnosis, making the malfunction clear at a glance.

Center input die head, eliminating the knit line completely and making it easy to change the material and color.

Double linear rolling motion guider in moving, opening and closing mold, making the clamping force equally distributed, so the cut is smoother.

Control the hydraulic system with imported proportional valve, ensuring the action steady, accurate and energy saving.

High speed and efficient plasticizing system, mixing well and ensuring the produce purity.

5 Gallon PC Bucket Automatic Blow Molding Machine Parameter:

Specifications | Unit | Parameters |

Max container capacity | L | 20 |

Extruder System |

|

|

Screw Diameter | mm | 82 |

Screw L/D ratio | L/D | 30:1 |

Screw Speed | rev. / min. | 10~50 |

Plasticizing Capacity | Seconds/die. | 60 |

Number of heating zone barrel | zone | 5 |

Extruder driving Power of barrel | KW | 34 |

Max Injection quantity | L | 1.5 |

Die Head |

|

|

Max die diameter | mm | 130 |

Number of heating zone | zone | 4 |

Extruder driving power | KW | 8.7 |

Clamping Device |

|

|

Platen Size(WxH) | mm | 440 x 600 |

Platen opening stroke | mm | 330~780 |

Clamping force | KN | 210 |

Next blowing Device |

|

|

Blowing the head off and landing trip | mm | 120 |

Manual control Blowing the head off and landing trip | mm | 80 |

Manipulator |

|

|

Take pieces of travel | mm | 1000 |

Framework |

|

|

Lift travel | mm | 250 |

Hydraulic System |

|

|

Rated pressure of big pump | Mpa | 14 |

Rated flow of big pump | L/min | 180 |

Motor power of Hydraulic pumps | KW | 45 |

Parison Controlling Of Hydraulic Servo System |

|

|

Rated pressure | Mpa | 6 |

Rated Flow | L/min | 22 |

Motor power of Hydraulic pumps | KW | 4 |

Pneumatical System |

|

|

Air source pressure | Mpa | 1 |

Working pressure | Mpa | 0.8 |

Air consumption | M3 / min. | 0.6 |

Electrical Control System |

|

|

Water Supply |

|

|

Water supply pressure | Mpa | 0.3 |

Power Supply | ||

Voltage | V | AC380V±10% |

Frequency | HZ | 50 |

Wire |

| 3Phase |

Total of rated power | KW | 91.7 |

Average power consumption | KW.h | 45 |

Total weight | Ton | 11 |

Dimension of machine (Lx W x H) | m | 5.3×2.7×4.5 |

5 Gallon PC Bucket Automatic Blow Molding Machine Parts Picture:

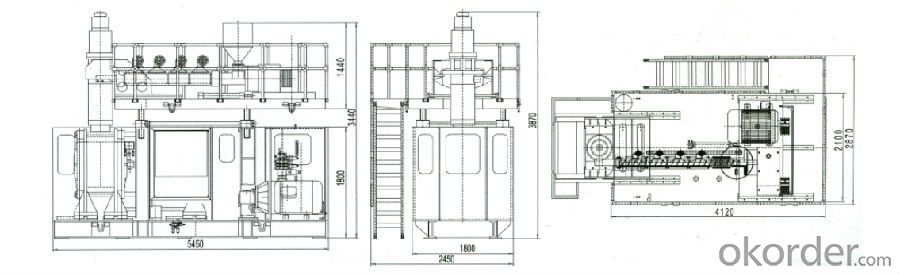

5 Gallon PC Bucket Automatic Blow Molding Machine Drawing Picture:

5 Gallon PC Bucket Automatic Blow Molding Machine Electrical Parts Photo:

5 Gallon PC Bucket Automatic Blow Molding Machine Products Photo:

- Q: I use the 300 frame oil filter to filter the oil. What size filter paper should I use?

- Compression method manual screw compressionThe ambient temperature of -25 to 70 DEG CThe medium temperature -25 to 90 DEG CPower 380V/50HZ (three-phase four wire) or according to customer needsThe noise is less than 70dBMotor power (KW) 5.5 KWThe inlet and outlet diameter is 60 mmEquipment weight 600KgOutline size 1600mm * 600mm * 1100mmThe continuous working time is more than 150hMTBF > 5000h

- Q: How often is the filter element of the transformer oil vacuum oil filter changed?

- If the oil is very dirty, recommended for cleaning, if not timely replacement of the cleaning of the filter sludge filter blocked, causing pressure to filter limit rupture, and no way to clean, only for the new.

- Q: What is the return of the oil filter?

- Do you filter it repeatedly or do you filter it at a time?

- Q: What is the reason for the oil running out of the turbine oil filter?

- Improvement measures for running oil in exhaust port of vacuum oil filter:Check the reasons for the failure to start the automatic heating of the sealing oil filter oil.Stop sealing oil filter before checking out the cause.Strengthen the operation inspection of the sealed oil filter, ensure the automatic operation of the oil pump, the oil pump and the electric heater chain, and carry out the transmission test regularly on the chain of sealed oil filter.Using the opportunity of unit overhaul to improve the exhaust pipe of sealed oil filter and vacuum pump, completely eliminate the hidden trouble of oil leakage of oil filter.Strengthen the training of operators, fully grasp the working principle of the sealed oil vacuum oil filter, as well as the matters needing attention in the operation process and the accident treatment.

- Q: Centrifugal oil filter speed is not fast before, what is the matter?

- Generally, it's a long time, and the belt is wearing and slipping. Or the screws are loose

- Q: Is there a national standard for oil filters?

- JB/T 53160-1999 frame pressure oil filter grading of product qualityPlate and frame type oil purifier (oil filter) is mainly used to filter transformer oil, turbine oil, oil, diesel oil, aviation hydraulic oil and other oil in water and impurities, the body is made of stainless steel, can be used as vegetable oil filter.

- Q: What is the principle of vacuum oil filters used in steam turbines?

- PX is the use of physical means, without affecting the moisture, impurity and gas contains a large number of rapid removal of oil oil components and the premise of the performance of the liquid (acetylene, hydrogen, methane and other harmful ingredients; etc.) can have on steam, Water Leakage, aging, acid, foam, emulsified oil product purification. The quality indexes of the oil products meet the requirements of the quality standard of turbine oil in operation of GB/T 7596-2008

- Q: The vane filter and the centrifugal oil filter are good

- But the accuracy of the filter is not high, and then the cost of the centrifuge, higher operating costs

- Q: Working principle and operation instructions of vacuum oil filter for oil press

- Vacuum pump to vacuum tank air to form a vacuum, outside the oil under the influence of the atmospheric pressure through the entrance pipe into the primary filter, remove larger particles, and then into the heating tank, heated by 40 degrees to 75 degrees of oil through the automatic oil float valve, this valve is automatic control into the vacuum tank of oil import balance, after heating the oil whirl through the spray wing separating oil into a mist, oil and water in the rapid evaporation of water vapor into the vacuum pump and continuous inhalation of condenser.

- Q: What is the difference or connection between the oil filter and the oil filter?

- The same function, one is installed in a part of a system, and the oil filter can move, do not need other devices can be completed independently

Send your message to us

Automatic Blow Molding Machine for 5 Gallon PC Bucket

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords