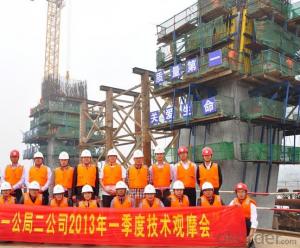

Auto-climbing Formwork with High Speed Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydraulic Auto-climbing Formwork

Introduction :

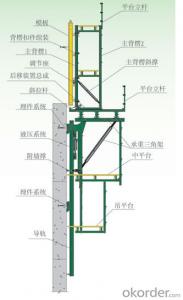

The lifting power of the Formwork QPMX-50 comes from its hydraulic system, which includes the oil cylinder and commutator. Through functioning of hydraulic system, the steel rail and bracket can climb up alternately, so the whole formwork system climbs steadily, independent of a crane. It' s easy to operate, and climbing is fast and safe.The power of the Auto-climbing Formwork is the hydraulic system, which includes the oil cylinder and two inverting boxes. The inverting boxes can control the climbing of climbing rail and the bracket. The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily. Cranes are not needed during the climbing. It's easy to operate, highly efficient and safe. It's the best choice for the construction of high buildings and large bridges.

There are mainly two types of standard auto-climbing formwork, ACS-50 and ACS-100.

Standard Climbing Process

1.Set up the formwork by wall-through tie-rods and pull-push props, embed anchors and do the first concrete pouring.

2. Remove the formwork after the first pouring and fix anchor shoes on the finished wall, lift the brackets and formwork to the right position, match the formwork and do the second pouring.

3.Lift formwork and brackets to the higher floor; fix climbing rail and hydraulic system.

4.Match the formwork to the right position and do the third pouring.

5.Strip the formwork and fix anchor shoes on the finished wall, then let the climbing rails climb.

6. Brackets climb up to the right position, then install suspended platform.

7.Match the formwork, do the concrete pouring, and proceed into the standard climbing stage.

Our services:

Consultancy

Offer you a general idea about formwork & scaffolding

Technical Planning

Customized forming & shoring solution proposal according to your structural drawing by Auto-cad

Logistics

Fast to your site with proper packages & well organized loadings

On-site supervision

Shop drawing, assembly drawing, and even send our supervisor to your site for training and supervision

FAQ

We can make plan of everything needed according to the project's structural drawing in Auto cad format or blueprint. In the CAD design, it clearly shows how to install every item with exact quantity.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- After the shift between the device and the main girder is inserted on the pin and the pin card, after the shift is already used for rear jacking jacking, wind cable is tightened, the adjacent frame between the climbing frame is firmly rachel.

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame installation processInstallation of platform --- display base, installation guide, assembling components - horizontal truss beam with the bolt on the guide rail, the main frame vertical rod buckle on the beam - diagonal rod buckle on the vertical rod and beam - wall installation guide device, the frame structure of unloading with elevated body, the erection of scaffolding, the laying of the intermediate layer or temporary scaffolding and temporary building structure frame of pulling and hanging outside the dense mesh safety net - loaded third beams to guide seat -

- Q: The difference between the scaffold and the scaffold

- The difference between climbing frame and scaffolding is commonly used scaffolding from below has been set up, which is followed by building up climbing frame, the figure is upstairs, they have in common is that we are like scaffolding

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- 2) easy to install and disassemble, set up flexible. Because the length of the steel tube is easy to adjust and the fastener is convenient to connect, the utility model can be used for various buildings and structures with various planes and elevations.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- . It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

Send your message to us

Auto-climbing Formwork with High Speed Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords