ASME API 5L Structural Seamless Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Welded Steel Tube:

Welded Steel Tube is formed by drawing a solid billet over a piercing rod to create the hollow shell. We are company that have many years experience and professional manager team and engineer team and sales team, sure we will provide you high quality of welded pipe and professioanl service. Our products are strictly in accordance with international and domestic standard. We test on every pipe before delivery. Any quality certification or testing report you want to see, please tell us. We aim to give your best service and hope to establish long-term business cooperation with you. Good quality and speedy delivery and patient after-sale service will help you make an easy purchase.

2、Main Features of the Welded Steel Tube:

• High manufacturing accuracy

• The higher strength

• The small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Satisfy price

3、Welded Steel Tube Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Welded Steel Tube:

①How is the quality of your products?

Our products are strictly in accordance with international and domestic standard. We test on every pipe before delivery. Any quality certification or testing report you want to see, please tell us.

Guaranteed: If products’ quality is not in accordance with description as we provide or the promise before you place order, we promise 100% refund.

②How about the price?

Yes, we are factory and be capable of offering you the lowest price. One of our policy is that “ to save time and be absolutely honest with our business relationship, we quote as low as possible for every client, and discount can be given according to the quantity”, if you are interested in bargain and dissatisfy our factory price, just don’t waste your time. Our quotation is professional.

③Why should you choose us?

Choice happens because of our quality and price. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), fast goods delivery, outstanding customer solution proposals. Our service formula: good quality + good price + good service=customer’s trust.

SGS test is available. Customer inspection before shipping is welcome. Third party inspection is OK. We aim to give your best service and hope to establish long-term business cooperation with you. Good quality and speedy delivery and patient after-sale service will help you make an easy purchase.

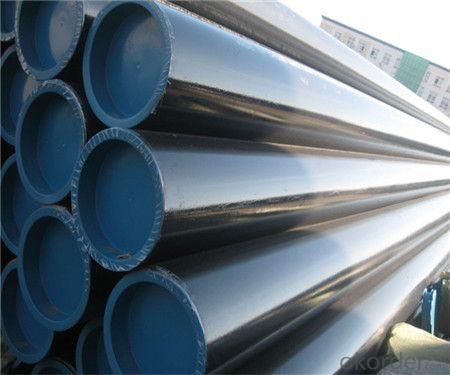

6、 Welded Steel Tube Images:

- Q: Are steel tubes and round steel in weight or length when purchased?

- A large amount of words is calculated by weight, less is usually calculated. According to the length between the length and quality of a material is usually a scaling. Steel belongs to the section, with the length of valuation, according to the classification of wall thickness and diameter; round steel belongs to building materials, mostly for the amount of weighing per ton of valuation, a small amount of more than according to the length multiplied by the conversion ratio of weight to that theory. But the latter is the valuation of tons of steel products between the uneven thickness, with uniform proportion will produce larger price difference, so the general price of different manufacturers are not the same, mostly depends on the quality, to a certain extent is to balance the diameter difference.

- Q: What is the difference between API 5L and ASTM A53 steel pipes?

- API 5L and ASTM A53 are two widely used standards for carbon steel pipes. While they both serve similar purposes, there are some key differences between them. 1. Scope: API 5L covers seamless and welded steel pipes for transportation of oil, gas, water, and other fluids. It also includes plain-end, threaded-end, and belled-end pipe types. On the other hand, ASTM A53 is a standard specification for seamless and welded black and hot-dipped galvanized steel pipes used for mechanical and pressure applications. 2. Manufacturing process: API 5L pipe is produced through a hot-rolling process, whereas ASTM A53 pipe is produced through a hot-rolling or cold-drawing process. This difference in manufacturing process affects the pipe's chemical composition and mechanical properties. 3. Chemical composition: API 5L pipe typically has a higher carbon content compared to ASTM A53 pipe. This is because API 5L pipe is used for conveying oil, gas, and water, which often require higher strength and durability. ASTM A53 pipe, on the other hand, is used for mechanical and pressure applications, where lower carbon content is suitable. 4. Mechanical properties: API 5L pipe has higher minimum yield strength and tensile strength compared to ASTM A53 pipe. This is due to the higher carbon content and stricter manufacturing process of API 5L pipe. ASTM A53 pipe has lower yield and tensile strength requirements, making it more suitable for general-purpose applications. 5. Coating options: API 5L pipe can be produced with various coating options such as black varnish, 3PE, FBE, and others, depending on the application requirements. ASTM A53 pipe is usually hot-dipped galvanized for corrosion resistance. In summary, API 5L and ASTM A53 steel pipes have different scopes, manufacturing processes, chemical compositions, mechanical properties, and coating options. Choosing the right pipe depends on the specific application requirements, such as the type of fluid being transported, the operating conditions, and the desired strength and durability.

- Q: What are the different methods of inspecting steel pipes for defects?

- There are several methods of inspecting steel pipes for defects, including visual inspection, magnetic particle testing, ultrasonic testing, radiographic testing, and eddy current testing.

- Q: Is steel pipe made of profiles?

- In accordance with the different smelting quality of steel, steel is divided into ordinary steel and high quality steel. According to the current catalogue of metal products, ordinary steel can be divided into large section steel, medium section steel and small section steel. The section steel can be divided into I-beam, channel steel, angle steel, round steel and so on according to its sectional shape.

- Q: How to identify stainless steel pipe and steel pipe?

- Steel pipe according to the production method can be divided into two categories: seamless steel pipe and pipe joints, pipe joints as welded steel pipe.1. seamless steel tube according to the production methods can be divided into: hot-rolled seamless pipe, cold drawn tube, precision steel tube, heat expansion tube, cold spinning tube and extrusion tube.Seamless steel tubes are made of high quality carbon or alloy steel. They are hot-rolled and cold-rolled (drawn).Bundled steel pipe2. welded steel pipe for different welding process and divided into the furnace pipe welding (ERW) pipe and automatic arc welding, because of the different forms of welding seam welded pipe and spiral welded pipe is divided into two kinds, end its shape is divided into circular welded and shaped (square, flat) pipe.

- Q: How do steel pipes compare to other materials like PVC or copper?

- Steel pipes have several advantages over other materials like PVC or copper. Firstly, steel pipes are incredibly strong and durable. They can withstand high pressure and extreme temperatures without cracking or bending. This makes them ideal for heavy-duty applications such as industrial piping systems or underground installations. Secondly, steel pipes have excellent corrosion resistance. Unlike copper pipes that can corrode over time, steel pipes are typically coated with anti-corrosive materials such as zinc or epoxy. This protective layer prevents rust and ensures a longer lifespan for the pipes. Furthermore, steel pipes offer superior fire resistance compared to PVC or copper. They are non-combustible and can withstand high temperatures for extended periods without deforming or releasing toxic gases. This makes steel pipes a safer option for applications where fire hazards are a concern. In terms of cost, steel pipes may be more expensive than PVC initially, but they offer better long-term value due to their durability and longevity. Copper pipes, on the other hand, can be quite expensive and are susceptible to theft due to their scrap value. Lastly, steel pipes are highly versatile and can be used in various applications, including water supply, sewage systems, gas pipelines, and oil refineries. They can handle high volumes of fluid with ease and are resistant to external factors like UV rays or physical impacts. Overall, steel pipes are a reliable and efficient choice for many industries and applications, offering strength, durability, corrosion resistance, fire resistance, and versatility that sets them apart from materials like PVC or copper.

- Q: What is the role of steel pipes in the renewable energy sector?

- Steel pipes play a crucial role in the renewable energy sector as they are commonly used for transporting various fluids, including water, steam, and gases, in renewable energy systems. They are extensively utilized in the construction of wind turbines, solar power plants, and geothermal installations. Steel pipes are employed for the transportation of water in hydroelectric power plants and for the transmission of heat in concentrated solar power systems. Additionally, they are instrumental in the distribution and storage of fuels such as hydrogen and biogas, which are vital components of renewable energy technologies. Overall, steel pipes provide a reliable and durable means of transporting resources and energy within the renewable energy sector.

- Q: What are the factors to consider when selecting the right steel pipe for a specific application?

- There are several factors to consider when choosing the appropriate steel pipe for a particular application. These factors encompass: 1. Compatibility with materials: Ensuring that the steel pipe is compatible with the substance it will transport or contain is crucial. Different materials may necessitate specific types of steel pipes to prevent corrosion or contamination. 2. Pressure and temperature requirements: The pressure and temperature conditions that the steel pipe will face should be taken into account. This will determine the necessary thickness and strength of the pipe to ensure it can withstand the intended operating conditions. 3. Size and dimensions: Selecting the size and dimensions of the steel pipe should be based on the flow rate, volume, and available installation space. It is vital to choose a pipe with the appropriate diameter and wall thickness to prevent flow restrictions or leaks. 4. Environmental conditions: The environment in which the steel pipe will be installed must be considered. Factors such as exposure to moisture, chemicals, or extreme temperatures may necessitate the use of specific coatings or materials to enhance the longevity and durability of the pipe. 5. Cost considerations: The cost of the steel pipe and its installation should be taken into account. Striking a balance between desired quality and available budget is essential to ensure the most cost-effective solution. 6. Regulatory compliance: Depending on the application, there may be specific industry regulations or standards that must be adhered to. Choosing a steel pipe that meets these requirements is important to ensure compliance and avoid any legal or safety issues. 7. Maintenance and lifespan: The maintenance requirements and expected lifespan of the steel pipe should also be considered. Some applications may require regular inspections or replacements, while others may require a more durable and long-lasting pipe. By carefully considering these factors, it is possible to select the appropriate steel pipe for a specific application that meets the desired performance, durability, and safety requirements.

- Q: How are steel pipes protected from damage during transportation?

- Steel pipes are protected from damage during transportation through various methods. One common method is the use of protective coatings. Steel pipes are often coated with materials such as epoxy, zinc, or polyethylene to create a barrier between the pipe and external elements. These coatings help to prevent corrosion and damage during transit. Furthermore, steel pipes are often bundled together and secured using straps or bands. This bundling helps to keep the pipes in place and prevents them from shifting or rolling during transportation. Additionally, padding or cushioning materials such as foam or rubber may be used to provide extra protection and minimize the risk of damage from impact or vibration. In some cases, steel pipes may be placed in crates or containers to provide additional protection. Crates are designed to fit the pipes snugly and provide a secure enclosure that prevents external forces from causing damage. Containers, on the other hand, offer a protective environment for the pipes, shielding them from the elements and potential impacts. To ensure the safe transportation of steel pipes, it is also important to consider proper handling and loading techniques. Pipes should be carefully lifted and loaded onto transport vehicles using appropriate equipment, such as cranes or forklifts, to minimize the risk of damage. Proper securing of the pipes within the transport vehicle is crucial to prevent movement and potential damage during transit. Overall, a combination of protective coatings, bundling, padding, and secure packaging or loading techniques are employed to safeguard steel pipes from damage during transportation. These measures help to ensure that the pipes arrive at their destination in optimal condition, ready for use in various applications.

- Q: Can steel pipes be used for oil refineries?

- Yes, steel pipes are commonly used in oil refineries due to their high strength, durability, and resistance to corrosion, making them suitable for transporting various petroleum products and chemicals within the refinery infrastructure.

Send your message to us

ASME API 5L Structural Seamless Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords