ASTM Standard Stainless Steel Seamless Pipe manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of ASTM Standard Stainless Steel Seamless Pipe:

ASTM Standard Stainless Steel Seamless Pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, ASTM Standard Stainless Steel Seamless Pipe are perceived to be stronger and more reliable. Historically ASTM Standard Stainless Steel Seamless Pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of ASTM Standard Stainless Steel Seamless Pipe:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、ASTM Standard Stainless Steel Seamless Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of ASTM Standard Stainless Steel Seamless Pipe:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

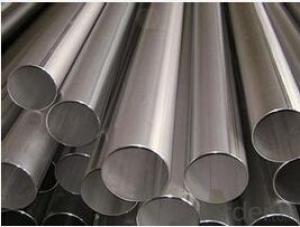

6、Seamless Pipe ASTM A106/53 Images:

- Q: How do you calculate the expansion of stainless steel pipes?

- To calculate the expansion of stainless steel pipes, you need to consider the coefficient of thermal expansion (CTE) of the material. The CTE is a measure of how much a material expands or contracts when subjected to temperature changes. First, determine the initial length of the stainless steel pipe. This is the length of the pipe at the starting temperature. Next, determine the final temperature at which the pipe will be operating. This is the temperature at which you want to calculate the expansion. Find the CTE value for the particular grade of stainless steel used in the pipe. The CTE is typically given in units of per degree Celsius (or per degree Fahrenheit). Multiply the initial length of the pipe by the CTE value and then multiply it by the change in temperature. This will give you the expansion or contraction of the pipe in the given temperature range. For example, let's say you have a stainless steel pipe with an initial length of 10 meters, a CTE of 17 x 10^-6 per degree Celsius, and you want to calculate the expansion at a final temperature of 100 degrees Celsius. The change in temperature would be 100 degrees Celsius (final temperature) minus the initial temperature. Expansion = Initial Length * CTE * Change in Temperature Expansion = 10 meters * 17 x 10^-6 per degree Celsius * 100 degrees Celsius Expansion = 0.0017 meters or 1.7 millimeters Therefore, the stainless steel pipe would expand by 1.7 millimeters when subjected to a temperature increase of 100 degrees Celsius. It's important to note that this calculation assumes a uniform expansion along the entire length of the pipe. In reality, thermal expansion may vary due to factors such as pipe diameter, wall thickness, and other structural considerations. Therefore, it's recommended to consult with industry standards or engineering references for more accurate calculations in specific applications.

- Q: Can stainless steel pipes be used for cryogenic storage tanks?

- Yes, stainless steel pipes can be used for cryogenic storage tanks. Stainless steel is known for its excellent corrosion resistance, durability, and strength, which make it suitable for storing extremely cold liquids or gases. Cryogenic storage tanks are designed to store materials at very low temperatures, typically below -150 degrees Celsius. Stainless steel pipes are capable of withstanding these low temperatures without becoming brittle or losing their mechanical properties. Additionally, stainless steel has low thermal conductivity, which helps to minimize heat transfer and maintain the desired temperature inside the storage tank. Therefore, stainless steel pipes are commonly used in cryogenic storage tanks to ensure the safe and efficient storage of cryogenic materials.

- Q: Are stainless steel pipes suitable for semiconductor industries?

- Yes, stainless steel pipes are suitable for semiconductor industries. Stainless steel offers excellent corrosion resistance, high temperature resistance, and cleanliness, which are essential requirements for the semiconductor industry. It is also non-reactive, ensuring the purity of the semiconductor materials. Additionally, stainless steel pipes can withstand the high-pressure conditions often found in semiconductor manufacturing processes.

- Q: Can stainless steel pipes be used for pulp and paper industry applications?

- Yes, stainless steel pipes can be used for pulp and paper industry applications. Stainless steel is a highly durable and corrosion-resistant material, which makes it suitable for various industrial applications, including those in the pulp and paper industry. The industry involves the transportation of corrosive chemicals and liquids, such as acids, bleaching agents, and solvents, which can degrade and corrode regular pipes over time. Stainless steel pipes, on the other hand, are resistant to corrosion and can withstand the harsh chemicals and high temperatures commonly found in pulp and paper plants. Additionally, stainless steel pipes are also hygienic and easy to clean, making them suitable for applications where cleanliness is essential, such as food-grade paper production. Overall, stainless steel pipes are a reliable and long-lasting choice for the pulp and paper industry.

- Q: Are stainless steel pipes resistant to chloride stress corrosion cracking?

- Generally, stainless steel pipes resist chloride stress corrosion cracking. Stainless steel is well-known for its ability to resist corrosion, even in chloride environments. The presence of chromium in stainless steel creates a protective layer on the surface that shields it from corrosion. This layer stops chloride ions from penetrating and reduces the risk of stress corrosion cracking. However, the resistance to chloride stress corrosion cracking can vary depending on the particular grade of stainless steel and the surrounding conditions. Therefore, it is crucial to select the appropriate stainless steel grade that offers sufficient resistance to chloride stress corrosion cracking for specific applications, particularly in high chloride environments like coastal areas or industrial settings.

- Q: In stainless steel tubes, why are there some SS in the back and some standard L, such as 316L and 316SS? What's the difference?

- 316: corresponding to China's brand 0Cr17Ni12Mo2316L: corresponding to Chinese brand 00Cr17Ni14Mo2316L steel is a low C series of 316 steel grades. It has better corrosion resistance except for the same characteristics as 316 steel.

- Q: How do you clean stainless steel pipes?

- To clean stainless steel pipes, there are a few methods you can use depending on the level of dirt or grime. Firstly, you can start by using warm water and a mild detergent. Mix the detergent with water and use a soft cloth or sponge to wipe down the surface of the pipes. Make sure to go in the direction of the grain to avoid scratching the steel. Rinse the pipes thoroughly with clean water and dry them with a clean, lint-free cloth. If the pipes have tougher stains or buildup, you can try using a vinegar solution. Mix equal parts of vinegar and water and apply the solution to the pipes. Allow it to sit for a few minutes to dissolve the stains, then scrub gently with a soft brush or cloth. Rinse the pipes well with clean water and dry them thoroughly. For more stubborn stains or discoloration, you can use a specialized stainless steel cleaner or polish. Follow the instructions on the product, usually applying it to the pipes and rubbing it in with a soft cloth. Again, make sure to go in the direction of the grain. Rinse the pipes thoroughly with clean water and dry them completely. It is important to note that abrasive cleaners or scrubbing pads should be avoided as they can scratch the stainless steel surface. Additionally, always test any cleaning solution or product on a small, inconspicuous area of the pipes before applying it to the entire surface to ensure it does not cause any damage or discoloration.

- Q: Can stainless steel pipes be used for pharmaceutical storage tanks?

- Yes, stainless steel pipes can be used for pharmaceutical storage tanks. Stainless steel is a preferred material in the pharmaceutical industry due to its high corrosion resistance, durability, and ability to maintain cleanliness. It is non-reactive, which helps prevent contamination of the pharmaceutical products stored in the tanks. Stainless steel pipes also offer a smooth and easy-to-clean surface, making it suitable for maintaining the required hygiene standards in pharmaceutical storage. Additionally, stainless steel is resistant to extreme temperatures and can withstand the rigorous cleaning procedures commonly used in pharmaceutical facilities. Thus, stainless steel pipes are commonly used in the construction of pharmaceutical storage tanks to ensure the safety and integrity of the stored pharmaceutical products.

- Q: Can stainless steel pipes be used for wastewater treatment?

- Stainless steel pipes are indeed suitable for wastewater treatment. This material, known for its resistance to corrosion, brings numerous advantages to applications in wastewater treatment. It is highly durable and can withstand exposure to aggressive chemicals and abrasive substances typically found in wastewater. Moreover, stainless steel pipes do not rust, ensuring a longer lifespan and minimizing the chances of pipe failure. In addition, stainless steel is inert and non-reactive, making it ideal for transporting and containing various types of wastewater without any risk of contamination. The smooth surface of stainless steel pipes also prevents the accumulation of deposits and biofilm, reducing the likelihood of clogging and allowing for the efficient flow of wastewater. All in all, stainless steel pipes present a dependable and sustainable choice for wastewater treatment systems.

- Q: Can stainless steel pipes be insulated with ceramic?

- Ceramic can indeed be used to insulate stainless steel pipes. It is commonly utilized in industrial settings that involve high temperatures. Ceramic insulation offers exceptional heat resistance and thermal insulation properties, making it an excellent choice. It can withstand extreme temperatures and effectively reduces heat transfer. Various industries utilize ceramic insulation to insulate pipes, tanks, furnaces, and other equipment. When applied to stainless steel pipes, ceramic insulation helps maintain the fluid's temperature, preventing heat loss or gain. Additionally, it provides protection against corrosion and mechanical damage. In summary, ceramic insulation is a suitable option for insulating stainless steel pipes in a wide range of applications.

Send your message to us

ASTM Standard Stainless Steel Seamless Pipe manufacturer

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords