ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

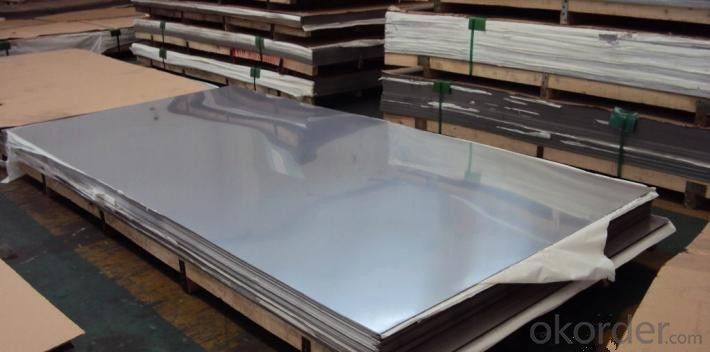

ASTM Standard 200,300,400 stainless steel sheet /Plate

1.Product introduction

We are the manufacturer! We produce stainless steel products with high quality & very competitive price!Please feel free to contact us for more information! | |

Product Name | ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate |

Standard | JIS AISI ASTM GB DIN |

Grade | 200/300/400 Series |

Thickness | 0.2mm-100mm |

Width | 100mm-2000mm |

Length | According to clients’ requirement |

Surface Finish | 2B ,BA ,8K ,NO4,NO2, NO1 ,Hair line ,EMBOSSED... |

Technique | Cold rolled ,Hot rolled |

Package | Seaworthy packing or as the consumers’ demand |

Application | Be used in manufacture of medical equipment, auto parts, heat-resistant kitchen utensils, electrical accessories , construction decoration ,etc |

Trade Term | FOB CIF |

Payment | T/T , L/C |

LoadingPort | Shanghai |

Delivery Time | 3-7days,mainly in accordance with the quantity |

Report | Material report ,Mechanical performance report |

Certification | ISO9001 |

2.Surface finishes and characteristic

Surface finish | Characteristics and application |

NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

NO.1 |

The surface is finished by heat treatment and pickling or processes corresponding thereto after hot rolling.

|

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Know more about trade...

Payment term: 1. 30% T/T in advance, and the balance against B/L copy

2. 100% irrevocable LC at sight.

Shipment date: Within 15-20 days after advance payment or receipt of LC

Trade term: 1. FOB Shanghai port, China.

2. CIF Discharging port

Guarantee& Service: Mill Test Certificate is supplied with shipment, and Third Part Inspection is acceptable.

Packing: standard export packing (plastic package to prevent water or plywood case to strengthen package)

- Q: What is the difference between stainless steel bars and stainless steel hexagons?

- The main difference between stainless steel bars and stainless steel hexagons lies in their shape. Stainless steel bars are straight and cylindrical in shape, while stainless steel hexagons have a six-sided hexagonal shape. This difference in shape makes stainless steel hexagons more suitable for certain applications where a hexagonal profile is required, such as in machinery or construction. On the other hand, stainless steel bars are versatile and can be used in a wide range of applications where a straight and cylindrical shape is preferred. Ultimately, the choice between stainless steel bars and hexagons depends on the specific requirements of the project or application.

- Q: Can stainless steel bars be used in chemical processing plants?

- Yes, stainless steel bars can be used in chemical processing plants. Stainless steel has excellent corrosion resistance properties, making it suitable for handling various chemicals and corrosive environments commonly found in chemical processing plants. Additionally, stainless steel bars offer high strength and durability, making them ideal for structural applications in these plants.

- Q: Are stainless steel bars suitable for architectural balustrades?

- Yes, stainless steel bars are highly suitable for architectural balustrades. Stainless steel is a durable and corrosion-resistant material, making it ideal for outdoor applications such as balustrades. It is also low maintenance, requiring minimal upkeep over time. Additionally, stainless steel has a sleek and modern appearance that can enhance the overall aesthetics of a building or structure. Stainless steel bars can be fabricated in various sizes and designs to suit different architectural styles and requirements. Overall, stainless steel bars provide a strong and secure railing solution for architectural balustrades.

- Q: Can stainless steel bars be used in the manufacturing of pressure vessels?

- Yes, stainless steel bars can be used in the manufacturing of pressure vessels. Stainless steel is often chosen for pressure vessel applications due to its high strength, corrosion resistance, and ability to withstand high temperatures. The use of stainless steel bars in pressure vessel manufacturing ensures the vessels can withstand the internal pressure and harsh operating conditions.

- Q: Can stainless steel bars be used in the power plant industry?

- In the power plant industry, stainless steel bars are highly valued due to their remarkable corrosion resistance, outstanding strength, and exceptional durability. This material proves suitable for a wide range of applications within this industry. Notably, these bars are utilized in the construction of crucial structural components like support beams, frames, and platforms. Moreover, they play a vital role in the manufacturing of essential equipment such as turbines, boilers, heat exchangers, and condensers. It is also worth mentioning that stainless steel bars are commonly employed in the creation of piping systems, where their resistance to corrosion and ability to withstand high temperatures are of utmost importance. Given their ability to endure extreme conditions prevalent in power plants, including high pressure, elevated temperatures, and exposure to various chemicals, these bars are consistently relied upon by professionals in this industry.

- Q: Can stainless steel bars be used in pharmaceutical applications?

- Stainless steel bars are indeed applicable for use in pharmaceutical settings. The pharmaceutical industry favors stainless steel due to its ability to resist corrosion, its durability, and the ease with which it can be cleaned. In the construction of pharmaceutical equipment, such as storage tanks, piping systems, and mixing vessels, stainless steel bars are frequently employed. This material's resistance to chemical reactions and contamination renders it suitable for the secure handling and storage of pharmaceutical products. Moreover, stainless steel can withstand high temperatures and pressures, making it an ideal choice for applications requiring sterilization or autoclaving. All in all, stainless steel bars fulfill the stringent requirements of pharmaceutical applications and are extensively utilized in the industry for their dependability and cleanliness.

- Q: Can stainless steel bars be used in construction projects?

- Certainly, construction projects can make effective use of stainless steel bars. This material, renowned for its versatility and durability, offers numerous advantages in construction applications. Its exceptional resistance to corrosion renders it particularly well-suited for environments exposed to moisture, chemicals, or severe weather conditions. In addition, stainless steel bars possess impressive strength-to-weight ratios, enabling the construction of robust yet lightweight structures. They find extensive use in the creation of bridges, buildings, infrastructure, and reinforcement applications like concrete reinforcement. Available in diverse sizes, shapes, and finishes, stainless steel bars can cater to a wide array of construction requirements.

- Q: What are the characteristics of austenitic stainless steel bars?

- Austenitic stainless steel bars possess exceptional resistance to corrosion, rendering them suitable for diverse applications across multiple industries. The presence of elevated levels of chromium and nickel is a prominent feature of these bars, contributing to their corrosion resistance. These elements facilitate the formation of a protective layer of oxide on the material's surface, effectively preventing rust and corrosion. Moreover, the high ductility and toughness exhibited by austenitic stainless steel bars facilitate easy fabrication and shaping into various forms and sizes. This characteristic allows for flexibility in design and construction. Additionally, these bars boast remarkable strength and are capable of withstanding high temperatures, making them ideal for deployment in extreme environments. Additionally, austenitic stainless steel bars possess commendable weldability, meaning they can be readily welded or joined to other materials without compromising their corrosion resistance or mechanical properties. This attribute makes them a favored choice for applications requiring robust and long-lasting connections. Furthermore, austenitic stainless steel bars possess a non-magnetic nature, which proves advantageous in certain industries, such as electronics and medical equipment manufacturing, where minimizing magnetic interference is crucial. This characteristic also enables easy differentiation from other types of stainless steel. In conclusion, the key attributes of austenitic stainless steel bars encompass excellent corrosion resistance, high ductility and toughness, favorable weldability, impressive strength, and a non-magnetic nature. These properties render them a widely utilized and versatile material in various industries, including construction, automotive, aerospace, and food processing.

- Q: What are the advantages of using stainless steel square bars?

- There are several advantages of using stainless steel square bars. Firstly, stainless steel is highly resistant to corrosion, which makes it suitable for various applications, especially in environments with high moisture or chemical exposure. Secondly, stainless steel square bars are known for their durability and strength, allowing for heavy-duty applications. Additionally, stainless steel has an attractive appearance and can be easily cleaned and maintained. Moreover, stainless steel is a sustainable and environmentally friendly material, as it can be recycled indefinitely without losing its properties. Lastly, stainless steel square bars offer versatility in terms of design and can be customized to meet specific requirements.

- Q: Can stainless steel bars be used in the power generation repair industry?

- The power generation repair industry can utilize stainless steel bars. Renowned for its exceptional resistance to corrosion and strength, stainless steel proves itself as an optimal material for numerous applications within this industry. To be specific, stainless steel bars are applicable in the repair and maintenance of various power generation equipment, including turbines, generators, and heat exchangers. These bars are particularly useful in the fabrication and repair of components necessitating high strength and resistance to corrosion, such as shafts, bolts, and fasteners. Moreover, stainless steel bars exhibit the capacity to endure high temperatures, rendering them suitable for deployment in power generation systems operating under extreme conditions. In conclusion, stainless steel bars offer durability, reliability, and outstanding performance, rendering them invaluable in the power generation repair industry.

Send your message to us

ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords