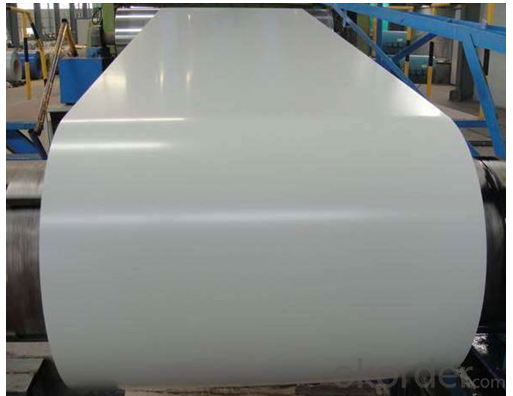

ASTM 615 VERY GOOD QUALTY PREPAINTED GALVANIZED STEEL COIL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

Very Good quality Prepainted galvanized steel coil Astm A615 ,with Gi as base metal after pretreatment ( degrease and chemical treatment) and liquid dope with several layers of color then after firing and cooling finally the plate steel is called Pre-painted galvanized steel is good capable of decoration ,molding corrosion resistance

Product Features

Excellent process capability

Smooth and flat surface

Workability durability

Excellent heat resistance performance

High Strength

Good formability

Good visual effect

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

1. How long will we receive the goods ?

45days after receiving workable L/C

2. how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: What are the common methods of packaging steel coils for transportation?

- There exists a variety of conventional techniques for packaging steel coils for transportation. One frequently employed approach involves the utilization of steel strapping or bands to fasten the coils together. This method entails tightly encircling the coils with steel bands and securing them using metal buckles or seals. The strapping serves to maintain the coils in position and prevent any shifting or rolling during transportation. Another popular technique entails the use of wooden pallets or skids to stack and transport the steel coils. The coils are positioned onto the pallets and secured with steel strapping or bands. This approach ensures stability and facilitates easy handling and loading onto trucks or other means of transportation. Furthermore, certain steel coils are enclosed within wooden crates or boxes. These crates are typically constructed from robust and durable wood and are designed to shield the coils from external impacts or damage during transportation. To enhance strength and stability, the crates are frequently reinforced with steel bands or strapping. In addition to the aforementioned methods, specialized containers or units are employed to package certain steel coils. These containers are specifically engineered to accommodate and secure steel coils for transportation. They often possess integrated mechanisms or features that facilitate the loading and unloading of the coils in a safer and more efficient manner. It is important to acknowledge that the particular method of packaging steel coils for transportation can vary depending on factors such as the size and weight of the coils, the mode of transportation, and any specific requirements or regulations that may be in effect.

- Q: What is the shelf life of a steel coil?

- The duration for which a steel coil remains usable depends on several factors, including the type of steel, storage conditions, and protective measures implemented. Steel coils can generally be stored for a few months to several years. If a steel coil is stored appropriately in a controlled environment with suitable temperature, humidity, and ventilation, its lifespan can be extended. Moreover, if the coil is coated with protective substances like oil or anti-corrosion coatings, its shelf life can be further prolonged. However, if a steel coil is exposed to unfavorable storage conditions such as high humidity, extreme temperatures, or corrosive substances, its shelf life can significantly decrease. Rust and corrosion can occur due to exposure to moisture and oxygen, leading to a decline in quality and structural integrity. To maximize the shelf life of a steel coil, it is crucial to store it in a well-ventilated, dry area, away from direct sunlight and corrosive substances. Regular inspections and maintenance, including cleaning and reapplication of protective coatings, can also help preserve the coil's quality. Ultimately, it is essential to consult the manufacturer or supplier of the steel coil for specific recommendations regarding shelf life, as different types of steel may have varying levels of durability and specific storage requirements.

- Q: What are the challenges faced in the recycling of steel coils?

- The recycling of steel coils presents several challenges that must be overcome. To start, the collection and sorting process poses a significant hurdle. Steel coils are often utilized in large-scale industries and construction projects, making it challenging to gather and transport them for recycling purposes. Moreover, steel coils can become mixed with other materials, such as plastic or wood, further complicating the sorting process. Another obstacle is the size and weight of steel coils. Given that steel is a heavy material, handling and processing large coils can be quite difficult. Specialized equipment and machinery may be necessary to efficiently move and separate the coils, thereby increasing the cost and complexity of the recycling process. Additionally, the recyclability of steel coils can be impacted by varying quality. These coils may contain impurities or contaminants, such as oil or paint, that must be eliminated before recycling. Such impurities can compromise the integrity and quality of the recycled steel, making it less desirable for certain applications. Moreover, the recycling of steel coils demands substantial energy and resources. Melting down the steel requires a significant amount of energy, while the transportation and processing of the coils also consume resources and contribute to carbon emissions. Consequently, the environmental friendliness of the recycling process can be diminished. Lastly, the viability of the recycling industry can be influenced by fluctuating market demand for recycled steel coils. The demand for steel products can vary depending on economic conditions and industry trends, making it challenging for recyclers to find buyers for their recycled coils. This can potentially result in stockpiling or disposal difficulties. In conclusion, while recycling steel coils offers environmental benefits and resource conservation, several challenges must be addressed for its successful implementation. These challenges encompass collection and sorting, handling and processing, quality control, energy and resource consumption, as well as market demand.

- Q: Is steel framing eco friendly? Why or why not.

- Most of it is made from recycled iron and steel. You can also climb a ladder carrying a dozen steel studs far easier than you can lumber studs. It is this latter part why it is so popular in some areas.

- Q: I have a steel support beam can you remove one of the poles . the steel beam set on sender blocks on both side of the foundation. I have three steel beams support beam across the basement,I just want to remove one pole, can that be done.

- There's no way I am giving advice here. Hire a contractor to actually look at the load bearing of the pole.

- Q: How are steel coils used in the manufacturing of wires?

- Steel coils are used in the manufacturing of wires by being uncoiled and then fed through a series of machines where they are drawn, stretched, and twisted to the desired diameter and shape. This process helps to strengthen the wires and make them more flexible for various applications such as electrical wiring, construction, and manufacturing.

- Q: Can steel coils be coated with ceramic?

- Yes, steel coils can be coated with ceramic. This coating provides several benefits such as increased corrosion resistance, improved heat resistance, and enhanced durability. Additionally, ceramic coating can also provide an aesthetic appeal to the steel coils.

- Q: How are steel coils protected from humidity?

- Steel coils are typically protected from humidity through a process called galvanization, where a layer of zinc is applied to the surface of the steel. This zinc coating acts as a barrier, preventing moisture from coming into contact with the steel and causing corrosion. Additionally, the coils may be stored in a controlled environment with low humidity levels to further protect them.

- Q: Steel is strong in both tension and compression. Concrete is only strong in compression, and is very fragile in tension. Plus, concrete is heavy--a huge drawback in, say, a bridge deck. And its fairly expensive. And it hides the condition of the steel embedded within it. So what does it bring to the table? Why use it at all?

- As a composite material, reinforced concrete can be an economical alternative to structural steel in building, bridge and other superstructures. Reinforced concrete can be formed into almost any shape in the field. The bulk of reinforced concrete material - the aggregates - can often be produced local to a project, reducing manufacturing cost. Reinforced concrete weight can be a benefit, resisting loads that cause displacement, uplift and overturning.

- Q: nylon sounds alot better but i want to keep the acoustic i have now. Is it proper to put nylon on an acoustic guitar meant for steel strings?

- As others have said, it is not recommended because the steel-string neck is meant to handle the tension of steel strings, and nylon strings have much less tension. It won't do any immediate damage, especially if you loosen your truss rod a full turn or two to compensate. But if you keep the nylon strings on for too long your neck may twist or warp irreversibly. I don't recommend doing it, but if you want to try it anyway, get nylon strings with ball ends (Martin makes Darco strings with ball ends, and there are also Black Diamond strings with ball ends). Putting nylon strings on a steel-string guitar is not nearly as bad as putting steel strings on a nylon-string guitar -- whatever you do, don't do that!

Send your message to us

ASTM 615 VERY GOOD QUALTY PREPAINTED GALVANIZED STEEL COIL

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords