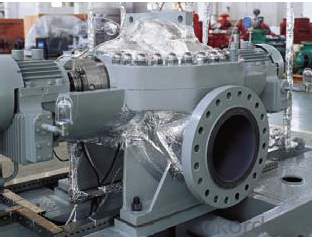

API 610 Double Suction Heavy-duty Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

API 610 Standard

Multistage Heavy Duty Axially Split Casing Centrifugal Pump

Water/Oil/Chemical

Q:6000m3/hr

H:1200m

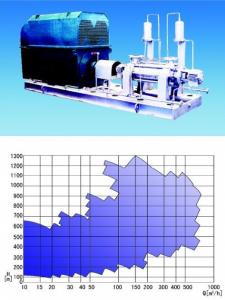

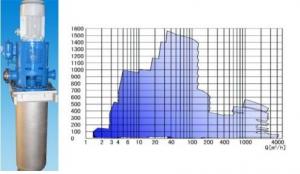

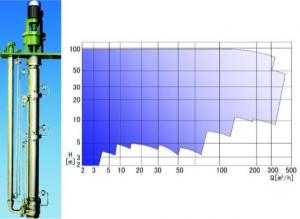

KSY/KDY Multistage Heavy Duty Axially Split Casing Centrifugal Pump

Application

Crude oil both in and off shore

In pipelines

Process plants

Refineries

Terminals

Sewage water with oil and solid

Boiler feed (Hot water pump)

General water supply

Sea water and hydrocarbons

Description

Horizontal axially split casing, double volute multistage design. Impellers arranged in opposed groups; KSY is a double suction two stage pump for bigger capacity. KDY is a multistage single suction impeller pump for higher head, first stage double suction impeller design for low NPSH required. Removable wear rings protect the casing and impeller. The impellers are statically and dynamically balanced. The pump complies with the API 610 specification latest edition in all technical details. Special antifriction bearings on both sides and sleeve bearings with ring or forced-feed lubrication (axial bearing as segmental thrust bearing).

According to ANSI/API 610 Tenth Edition, October, 2004.

Specifications

Capacity: up to 6000 m³/h ( up to 26400 gpm)

Head:up to 1200 m ( UP TO 2930 feet)

Temperature:up to 200oC (up to 380oF)

Speed: 2900/1450/980rpm or 3500/1750/1180rpm

- Q: My car oil pump pressure is low, engine oil alarm idling always ring, how to do?

- 1, lack of oil2, the oil leak, resulting in oil spills3. engine oil sensor fault causes oil lamp to be often bright

- Q: How does the motor pump exhaust the air?

- The oil pump is not required to take the air, booster pump, brake pump, water pump, clutch pump is the need to take the air, air film method is complicated, the need to add new oil, suggest you go directly to the repair shop repair station

- Q: What is the function of the oil pump?

- The oil pump is used to press the oil in the oil pan to the filter, and the engine oil can still be reliably conveyed to the friction surfaces of each lubricating oil passage and the moving parts after the filter is passed. When the engine is working, the oil pump keeps working to keep the oil circulating in the oil circuit. If damaged, there may be noise, noise, power attenuation, if not in time, even the cylinder can not start, the engine completely scrapped!

- Q: Will it clog up the oil pump by cleaning the engine oil which is strong enough to clog up the oil circuit?

- It is best not to use, if used with serious consequences, for you hold tile, cylinder, I have seen this kind of situation, buy a second-hand car home, clean diesel engine, the results of delaware,. The cleaning out of coke, will plug the filter, oil radiator, oil cylinder and rocker hole nozzle, gear chamber tube, not a small smart, or product produced by formal manufacturers, no problem.

- Q: How tight is the screw for the car engine oil pump?

- In the gasoline injection system, the fuel pump is an extremely critical component, once the fuel pump fails, the car will have a variety of adverse symptoms.First, the fuel pump failure, what problems will bring to the car?1, the engine can ignite, but can not start2 the fuel pump may leak inside3, excessive noise4, lack of motivation5. When you hesitate, speed upTwo, maintenance suggestions1. Most modern electric fuel pumps for automobiles are installed in the tank. Some vehicle access panels can be removed by replacing the pump without removing the fuel tank.2, tank fuel pumps are submerged in fuel to help them stay cool. The gas will destroy the fuel pump.3, fuel filter replacement fuel pump should be replaced4 fuel filter obstruction or electrical system driving fuel pump problems may cause symptoms similar to a failed fuel pump. The store confirms that the pump is in place before replacing it.5, gasoline is highly flammable. When replacing the fuel pump, the battery should be disconnected and proper safety procedures are provided to avoid fire and personal injury.

- Q: Does the oil pump plug cause less oil?

- The oil pump plug will not cause any reduction in engine oil, which will only result in the following two results:1. oil pressure drop, oil flow decreases, the appearance of insufficient lubrication2., serious blockage will cause oil in the oil pipe can not flow, causing the normal operation of the components to form "dry grind", accelerating the wear rate of parts

- Q: Why is the Honda engine oil pump so big? What's the function of the other parts?

- Hello, here is the balance shaft.

- Q: I don't understand. How can the internal parts be bad, depend on it, it's depressing

- Pull in the water or burn the oil

- Q: Accord 2 is timing, how about the oil pump?

- Hello, there are also some of the pump, on a black spot after even a little bit. And two black spots, a black spot on the point on the crankshaft, the two point of the oil pump is point, how many chains count on both sides, there is several chains Zhang tensioner!

- Q: GY6 engine oil pump installation direction, there is an arrow pointing to the other side of the ah

- The direction of the arrow indicates the direction of the oil, and the one with the arrow is connected to the engine oil inlet.

Send your message to us

API 610 Double Suction Heavy-duty Centrifugal Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords