OH2 Centrifugal Oil Pump (ZHY Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OH2 Centrifugal Oil Pump (ZHY Series)

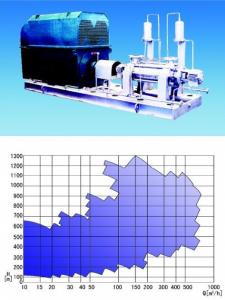

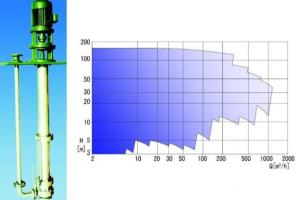

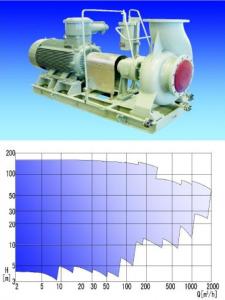

1. Specifications of OH2 Centrifugal Oil Pump:

Capacity: Q = 5~2600 m3/h

Head: H = 15~250 m

Working temperature: T = - 45~450 degree centigrade

2. Application of OH2 Centrifugal Oil Pump:

Petro refining

Petrochemical industry

Low temperature projects

Chemical fiber and common industry process

Power plants, heating systems or air conditioning systems

Environment protection projects

3. Description of OH2 Centrifugal Oil Pump

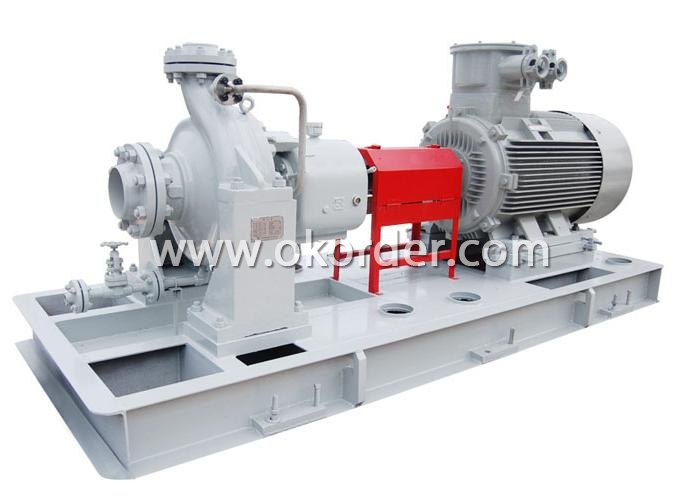

OH2 Centrifugal Oil Pump with feet, end suction and radial upward discharge, Hydraulic balance provided by front or rear wear rings and balance holes, shaft seal by packing or mechanical seal, connections for cooling, flushing or seal liquid, Pump clockwise rotation viewed from the driven end.

The pump is designed and made under API610, latest edition, and VDMA2497.

Flange is made as per DIN or AISI standard.

- Q: What is the oil pump on the car? If it is blocked, how can I solve it?

- The function of the oil pump is to send the oil to the friction parts of the engine, so that the engine oil is circulating in the lubrication road to ensure the engine to be well lubricated.

- Q: What's the use of an oil pump in an automobile engine?

- When the engine is transported within pump oil lubrication parts inside the engine.

- Q: How does the motor pump exhaust the air?

- The oil pump doesn't exhaust the air

- Q: What about the oil leakage of automobile oil pump?

- If the oil pump is broken, replace it, if it is a rubber pad, change the cushion.An oil pump in a lubricating system that forces the oil from the oil pan to the engine moving parts. Used to increase the pressure of the oil and to ensure a certain amount of oil.

- Q: The oil pump is coming up. Why is the oil lamp still on?

- This may be because the oil pressure is too low. Or the sensor itself is having problems.

- Q: The carbon pump is blocked, the Walla fell, the total amount of money to clean the engine?

- Hello, you can't clean it. It needs to be overhauled

- Q: JMC 462Q engine does not go to the cylinder head, where is the oil pump located?

- Looking for an oil pump? Remove the oil shell if not in crankshaft ends, also is not necessarily the reason for the oil pump, you can manually turn the crankshaft speed, if the starter for pull so I believe you may be more painful!

- Q: What is the difference between an oil pump and a gear pump?

- The oil pump is a kind of gear pump.

- Q: SUZUKI motorcycle oil pump is not on the oil, the oil circuit is not blocked, to replace the oil pump, or pump is not on the oil

- Is the oil filter and the oil filter plugged? Is the filter core apron missing? How do you make sure there's no blockage? No reason for the oil is only the oil pump damage, filter, filter or oil clogged, lack of oil and several other reasons.

- Q: TOYOTA Camry oil pump how to change?

- To fall apart, engine, gearbox, valve cover, timing cover, timing chain, gear, oil pan, then you can disassemble the pump replacement.

1. Manufacturer Overview

| Location | Liaoning,China |

| Year Established | 1990 |

| Annual Output Value | |

| Main Markets | Russia, Iran, north Korea, Vietnam, Sudan |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

OH2 Centrifugal Oil Pump (ZHY Series)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 Per Month unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords