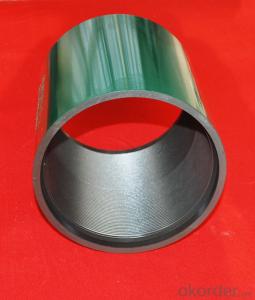

API 5CT Oil Casing Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PSL1 OIL CASING

API 5CT PSL1 OIL CASING TUBE PRODUCT SPECIFICATION

NO. | STEEL GRADE | SPECIFICATION | APPLICATIVE NORMAL | ||

OD /mm | WT /mm | LENGTH /m | |||

1 | H40 J55 K55 | 48~114 114~340 | 4~16 4.5~36 | 6~12.2 6~15 | API 5CT |

2 | M65 N80-1 N80Q R95 L80-1 C90-1 T95-1 C110 P110 Q125-1 | 48~114 114~340 | 4~16 4.5~36 | 6~12.2 6~15 | |

FAQ of API 5CT Oil Casing Tube:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

API 5CT Oil Casing Tube Images

- Q: How are steel pipes used in the construction of wastewater treatment plants?

- Steel pipes are commonly used in the construction of wastewater treatment plants due to their durability, strength, and corrosion resistance. These pipes are used to transport wastewater from different points within the treatment plant, such as pipes for raw sewage, sludge, and treated water. Additionally, steel pipes are also used for structural purposes, such as supporting tanks and other equipment. Overall, steel pipes play a crucial role in the efficient and reliable operation of wastewater treatment plants.

- Q: What is the role of steel pipes in the construction of bridges and tunnels?

- Steel pipes play a vital role in the construction of bridges and tunnels as they provide structural support and durability. They are commonly used for the fabrication of the framework and foundation of these infrastructures. Steel pipes offer high tensile strength, corrosion resistance, and the ability to withstand heavy loads, making them an ideal choice for ensuring the integrity and longevity of bridges and tunnels. Additionally, steel pipes can be easily welded, allowing for efficient and cost-effective construction methods.

- Q: How are steel pipes used in the manufacturing sector?

- Steel pipes are commonly used in the manufacturing sector for various purposes, such as transporting fluids and gases, providing structural support, and facilitating the flow of materials in manufacturing processes. They are used in industries like construction, oil and gas, automotive, and aerospace for applications such as pipelines, machinery, conveyors, and infrastructure. Steel pipes offer durability, strength, and resistance to corrosion, making them an ideal choice for many manufacturing needs.

- Q: How are steel pipes used in the construction of shipbuilding?

- Steel pipes are used in shipbuilding for a variety of purposes, including the construction of the ship's framework, hull, and various onboard systems. These pipes provide structural strength and durability, allowing the ship to withstand the harsh conditions at sea. They are also used for piping systems, such as fuel, water, and ventilation, ensuring the efficient operation of the vessel.

- Q: How are steel pipes used in the manufacturing of offshore wind turbines?

- Steel pipes are used in the manufacturing of offshore wind turbines for various purposes. They are commonly used to create the foundation structures, such as monopiles and jacket structures, which provide stability and support for the turbines in the seabed. Steel pipes are also utilized for the construction of the tower and nacelle structures, providing a strong and durable framework for the turbine components. Additionally, steel pipes are employed for the installation of subsea cables, allowing for the transmission of electricity generated by the turbines to the shore. Overall, steel pipes play a crucial role in the manufacturing of offshore wind turbines by providing the necessary strength, stability, and infrastructure required for their operation.

- Q: How do steel pipes handle ground freezing and thawing?

- Steel pipes are highly resistant to the effects of ground freezing and thawing. The inherent strength and durability of steel make it an ideal material for handling these thermal cycles. When the ground freezes, steel pipes are able to withstand the expansion forces exerted by the freezing water without any significant damage. The structural integrity of steel pipes remains intact even under extreme cold conditions. During thawing, steel pipes also fare well due to their ability to contract without compromising their strength. The material's flexibility ensures that it can accommodate the contraction of the ground without causing any structural issues. Steel pipes do not crack or break when exposed to the rapid temperature changes associated with thawing. Furthermore, steel pipes have a smooth internal surface, which reduces the risk of ice formation and subsequent blockages. This is particularly important in areas with frequent freezing and thawing cycles, as it helps to maintain a consistent flow of fluids or gases through the pipes. In summary, steel pipes are an excellent choice for handling ground freezing and thawing. Their strength, durability, and ability to withstand temperature fluctuations make them a reliable and long-lasting solution in such environments.

- Q: What is the role of steel pipes in HVAC systems?

- Steel pipes are crucial components in HVAC systems as they are used to transport hot and cold water throughout the system. They provide a durable and reliable means of distributing heat or cooling energy to various parts of a building. Steel pipes are known for their high strength and resistance to corrosion, making them an ideal choice for HVAC applications.

- Q: How are steel pipes coated to prevent external corrosion?

- Steel pipes are commonly coated to prevent external corrosion through various methods such as applying a layer of protective paint, using epoxy or polyethylene coatings, or galvanizing the pipes by applying a zinc layer. These coatings act as barriers against moisture and other corrosive elements, ensuring the longevity and durability of the steel pipes.

- Q: How are steel pipes used in the manufacturing of bridges?

- Steel pipes are commonly used in the manufacturing of bridges for various purposes, such as supporting heavy loads, providing structural strength, and ensuring durability. They are often used as piling foundations, allowing the bridge to be securely anchored to the ground. Steel pipes can also be used as bridge components, such as support columns, beams, and trusses, providing the necessary strength and stability to withstand the weight and forces exerted on the bridge. Additionally, steel pipes are used for drainage systems, allowing water to flow away from the bridge structure, preventing potential damage or erosion. Overall, steel pipes play a crucial role in the construction and structural integrity of bridges.

- Q: Can steel pipes be used for piling?

- Certainly, piling can involve the utilization of steel pipes. Steel pipes find widespread use in piling applications owing to their robustness, endurance, and adaptability. They possess the ability to endure the weight and pressure exerted by the soil, thus furnishing a steadfast base for constructions. The process of driving specialized equipment ensures the secure placement of steel pipes employed for piling. Moreover, steel pipes can be effortlessly trimmed and fused to the desired dimensions, rendering them suitable for diverse piling endeavors.

Send your message to us

API 5CT Oil Casing Tube

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords