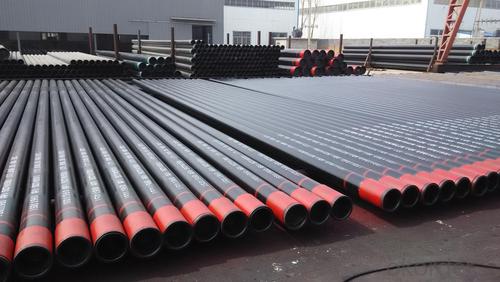

API Standard Oil and Gas Well Casing Tube 5CT

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Integral-joint tubing upsetting at one end, external threading, and external upsetting at the other end, internal threading. API integral-joint tubing is on the market in OD dimensions of 1.315 to a couple of.063 inch.

API integral-joint tubing provides 10-round form together with a joint strength which is less than the body minimum yield, this reduces its use.

The small OD of integral-joint tubing enables its use inside of larger tubing strings or inside of wells as unloading or vent strings.

The couplings will need to meet all the minimum specifications outlined in API Spec. 5CT. API Spec. 5B3 and API RP 5B14 cover threading, gauging, and thread inspection.

Specifications

| Parameters | Value | |

|---|---|---|

| Material | J55, K55, N80, N80Q, L80, P110, other grade available as your requirement | |

| Outer Diameter | 2-3/8"~4-1/2" (73.02~114.3mm) | |

| Wall Thickness | 4.83~16mm | |

| Forms of Thread | EUE, NUE and Integral-joint | |

| Length Range | R1(20~24ft), R2(28~32ft) | |

| MTR | accordance with API Specification 5CT |

Tolerances

| Parameters | Value | |

|---|---|---|

| Outside diameter | +-0.031 inch (0.79mm) | |

| Wall thickness | -12.5%, positive deviations are limited by pipe weight | |

| Weight Deviation | +6.5% /-3.5% |

Mechanical Properties

| Grade | Tensile Strength (PSI/MPa) | Yield Strenght (PSI/MPa) | ||

|---|---|---|---|---|

| H-40 | No less than 60000(414) | Between 40000 (276) ~ 80000 (552) | ||

| J-55 | No less than 75000 (517) | Between 55000 (379) ~ 80000 (552) | ||

| N-80 | No less than 100000 (689) | Between 80000 (552) ~ 110000 (758) | ||

| P-110 | No less than 125000 (862) | Between 110000 (758) ~ 140000 (965) |

Inspection

Physical properties are checked and each length hydrostatically tested, normally to only 3,000 psi in the plain end (unthreaded) condition. The following are also checked:

Dimensions

Weights

Straightness

Lengths

Part of this inspection is to drift all lengths.

Despite all the American Petroleum Institute (API) specifications and testing, some tubing defects are still found after delivery; thus, some operators do further inspection.

Inspection Method

Size and surface inspection

NDT and pressure test and third party certication

Hydrostatic

Drifting test

Physical and chemicail analysis

Hardness and pressure test.

Electromagnetic

Magnetic particle

Ultrasonic

Dimensions and Weight

| sizes | OD D mm | weight | wt t mm | Type of end | |||||||||||

| 1 | 2 | NU kg/m | EU kg/m | IJ kg/m | |||||||||||

| NU | EU | IJ | |||||||||||||

| H40 | J55 | L80 | N80 1/Q | C90 | T95 | P110 | |||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 2-3/82-3/8 2-3/8 2-3/8 2-3/8 | 4.004.60 5.80 6.60 7.35 | -4.70 5.95 - 7.45 | – - - - | 60.3260.32 60.32 60.32 60.32 | 5.956.85 8.63 9.82 10.94 | -6.99 8.85 - 11.09 | – - - - | 4.244.83 6.45 7.49 8.53 | PUPNU - - - | PNPNU - - - | PNPNU PNU P PU | PNPNU PNU - - | PNPNU PNU P PU | PNPNU PNU P PU | -PNU PNU - - |

| 2-7/82-7/8 2-7/8 2-7/8 2-7/8 2-7/8 | 6.407.80 8.60 9.35 10.50 11.50 | 6.507.90 8.70 9.45 - - | – - - - - | 73.0273.02 73.02 73.02 73.02 73.02 | 9.5211.61 12.80 13.91 15.63 17.11 | 9.6711.76 12.95 14.06 - - | – - - - - | 5.517.01 7.82 8.64 9.96 11.18 | PNU- - - - - | PNU- - - - - | PNUPNU PNU PU P P | PNUPNU PNU - - - | PNUPNU PNU PU P P | PNUPNU PNU PU P P | PNUPNU PNU - - - |

| 3-1/23-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7.709.20 10.20 12.70 14.30 15.50 17.00 | -9.30 - 12.95 - - - | – - - - - - | 88.9088.90 88.90 88.90 88.90 88.90 88.90 | 11.4613.69 15.18 18.90 21.28 23.07 25.30 | -13.84 - 19.27 - - - | – - - - - - | 5.496.45 7.34 9.52 10.92 12.09 13.46 | PNPNU PN - - - - | PNPNU PN - - - - | PNPNU PN PNU P P P | PNPNU PN PNU - - - | PNPNU PN PNU P P P | PNPNU PN PNU P P P | -PNU - PNU - - - |

| 44 4 4 4 4 | 9.5010.70 13.20 16.10 18.90 22.20 | -11.00 - - - - | – - - - - | 101.60101.60 101.60 101.60 101.60 101.60 | 14.14- 19.64 23.96 28.13 33.04 | -16.37 - - - - | – - - - - | 5.746.65 8.38 10.54 12.70 15.49 | PNPU - - - - | PNPU - - - - | PNPU P P P P | PNPU - - - - | PNPU P P P P | PNPU P P P P | – - - - - |

| 4-1/24-1/2 | 12.6015.20 | 12.75- | – | 114.30114.30 | 18.7522.62 | 18.97- | – | 6.888.56 | PNU- | PNU- | PNUP | PNU- | PNUP | PNUP | – |

| 4-1/24-1/2 4-1/2 4-1/2 4-1/2 | 17.0018.90 21.50 23.70 26.10 | – - - - | – - - - | 114.30114.30 114.30 114.30 114.30 | 25.3028.13 32.00 35.27 38.84 | – - - - | – - - - | 9.6510.92 12.70 14.22 16.00 | – - - - | – - - - | PP P P P | – - - - | PP P P P | PP P P P | – - - - |

| P——Plain end;N—Non-upset threaded and coupled;U—External upset threaded and coupled;I—insert joint. | |||||||||||||||

- Q: Can steel pipes be used for architectural purposes?

- Yes, steel pipes can be used for architectural purposes. Steel pipes are often used in construction projects for structural support, such as in the construction of buildings, bridges, and stadiums. They are also commonly used for architectural design elements, such as handrails, staircases, and decorative features. The durability, strength, and versatility of steel pipes make them a popular choice in architectural applications.

- Q: Can steel pipes be used for transporting sewage?

- Yes, steel pipes can be used for transporting sewage. They are commonly used in sewage systems due to their durability, strength, and resistance to corrosion.

- Q: What is the difference between steel pipe and tubing?

- The main difference between steel pipe and tubing lies in their shape and size. Steel pipe is typically cylindrical in shape and has a larger diameter compared to tubing, which is generally produced in a variety of shapes, including round, square, and rectangular, with smaller diameters. Additionally, steel pipe is commonly used for transporting fluids and gases, while tubing is often utilized for structural applications or as components in mechanical systems.

- Q: Can steel pipes be used for the construction of railway tracks?

- No, steel pipes cannot be used for the construction of railway tracks. Railway tracks require specially designed rails made of steel, which are laid on sleepers or ties and secured with fasteners to provide stability and support for trains. Steel pipes do not possess the necessary shape or strength required for this purpose.

- Q: What is the bending strength of steel pipes?

- The bending strength of steel pipes refers to the ability of a steel pipe to withstand bending forces without breaking or permanently deforming. The bending strength of steel pipes can vary depending on various factors such as the type and grade of steel, the diameter and thickness of the pipe, and the manufacturing process. Steel pipes are known for their high strength and durability, making them suitable for a wide range of applications. The bending strength of steel pipes is typically expressed in terms of the maximum bending moment or the maximum stress that the pipe can withstand without failure. To determine the bending strength of a steel pipe, engineers and manufacturers use various testing methods such as three-point or four-point bending tests. These tests apply a known force or moment to the pipe and measure its deflection or stress response. The bending strength of steel pipes can also be influenced by the pipe's mechanical properties, including yield strength, tensile strength, and elongation. These properties determine the overall strength and ductility of the steel, which play a vital role in its bending strength. It is important to note that the bending strength can vary depending on the specific application and load conditions. For example, pipes used in structural or load-bearing applications may require higher bending strength compared to pipes used for plumbing or conveyance purposes. In summary, the bending strength of steel pipes is determined by various factors such as the type and grade of steel, diameter and thickness of the pipe, and the manufacturing process. Testing methods and mechanical properties are used to evaluate the bending strength of steel pipes, ensuring their suitability for different applications and load conditions.

- Q: How are steel pipes used in the manufacturing of wind turbines?

- Steel pipes are an integral component in the manufacturing of wind turbines, primarily in the construction of the tower and the foundation. The tower of a wind turbine is typically constructed using large steel pipes that are welded together to form a sturdy and tall structure. These pipes provide the necessary strength and stability to support the entire weight of the wind turbine and withstand the strong forces generated by the rotating blades. In addition to the tower, steel pipes are also used for the foundation of the wind turbine. The foundation requires a strong and stable base to ensure the turbine remains upright and secure. Steel pipes are commonly used to create the deep foundation piles that are driven into the ground to provide support and stability. These piles are typically made of thick-walled steel pipes, which are driven deep into the ground to anchor the wind turbine and prevent it from toppling over. Furthermore, steel pipes are utilized in the transportation of electricity generated by wind turbines. Once the wind turbine converts wind energy into electrical energy, the electricity is transmitted through an internal electrical system to the base of the tower. From there, the electricity is often transferred through underground cables to a substation for distribution into the power grid. Steel pipes are used to protect and encase these cables, providing insulation and ensuring the safe transmission of electricity. Overall, steel pipes play a crucial role in the manufacturing of wind turbines by providing structural support, stability, and efficient transmission of electricity. The durability and strength of steel make it an ideal material for withstanding the harsh environmental conditions and the immense forces associated with wind turbine operation.

- Q: The plastic pipe and steel pipe difference

- The steel plastic pipe is a general term, which includes plastic pipe, plastic lined pipe. Plastic pipe external coating, zinc coated and so on in Shanghai, Fujian, Portland, professional in this area

- Q: How are steel pipes used in HVAC systems?

- Steel pipes are used in HVAC systems for various purposes such as transporting hot or cold water, steam, or refrigerant throughout the system. They are commonly used for supply and return lines, as well as for connecting various HVAC components like chillers, boilers, air handlers, and heat exchangers. Steel pipes are preferred in HVAC systems due to their durability, strength, and resistance to corrosion and high pressure.

- Q: How are steel pipes protected against corrosion in marine environments?

- Steel pipes are protected against corrosion in marine environments through various methods, such as applying protective coatings, using sacrificial anodes, employing cathodic protection, and implementing corrosion inhibitors.

- Q: What does "buried steel pipe" 6*2SC100 mean?

- The embedded steel pipe 6*2SC100 refers to a welded steel pipe with 2 pipe thicknesses of 6mm and a diameter of 100mm. SC pipe means welded steel pipe. Embedment means pre installation (burial).

Send your message to us

API Standard Oil and Gas Well Casing Tube 5CT

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords