Amino Trimethylene Phosphonic Acid Liquid And Solid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

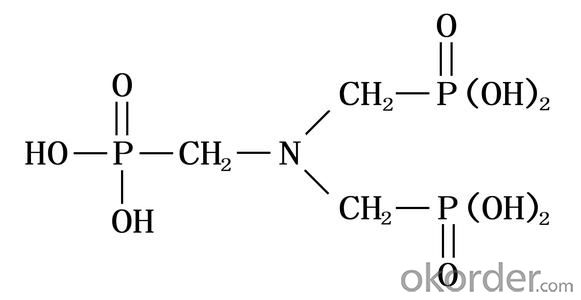

Amino tris(methylene phosphonic acid) / Amino Trimethylene Phosphonic Acid/ ATMP / 6419-19-8 / C3H12NO9P3

CAS No. 6419-19-8

Molecular Formula: N(CH2PO3H2)3

Molecular weight: 299.05

Structural Formula:

Properties:

ATMP has excellent chelation, low threshold inhibition and lattice distortion ability. It can prevent scale formation, calcium carbonate in particular, in water system. ATMP has good chemical stability and is hard to be hydrolyzed in water system. At high concentration, it has good corrosion inhibition.

ATMP is used in industrial circulating cool water system and oilfield water pipeline in fields of thermal power plant and oil refinery plant. ATMP can decrease scale formation and inhibit corrosion of metal equipment and pipeline. ATMP can be used as chelating agent in woven and dyeing industries and as metal surface treatment agent.

The solid state of ATMP is crystal powder, soluble in water, easily deliquescence, suitable for usage in winter and freezing districts. Because of its high purity, it can be used in woven & dyeing industries and as metal surface treatment agent.

Specification:

| Items | Index | |

|---|---|---|

| Standard | Solid | |

| Appearance | Clear, Colorless to pale yellow aqueous solution | White crystal powder |

| Active acid % | 50.0-51.0 | 95.0min |

| Chloride (as Cl-)% | 1.0 max | 1.0 max |

| pH value (1% solution) | 2.0 max | 2.0 max |

| Fe,mg/L | 10.0max | 20.0max |

| Density (20°C)g/cm3 | 1.31-1.35 | - |

| Colour APHA (Hazen) | 30.0max | - |

Application range&using method:

ATMP is usually used together with other organophosphoric acid, polycarboxylic acid and salt to built all organic alkaline water treatment agent. ATMP can be used in many different circulating cool water system. The recommended dosage is 5-20mg/L. As corrosion inhibitor, The recommended dosage is 20-80mg/L.

Package and Storage:

ATMP liquid: Normally In 30kg or 250kg net Plastic Drum;ATMP solid: 25kg inner liner polyethylene (PE) bag, outer plastic woven bag, or confirmed by clients request.Storage for ten months in room shady and dry place.

Safety Protection:

ATMP is Acidity, Avoid contact with eye and skin, once contacted, flush with water.

Shipping Date: Within 7-10 workdays after receiving your deposit.

Our Service:

Own Lab and joint venture factory.

Superb r&d team;Safety standardization production.

Rich experience in export and strong logistical support.

Good relationship with many large domestic pharmaceutical factory.

Perfect service, perfect supply chain.

- Q: High school chemistry, catalyst activation energy map

- Catalytic reaction is the reaction of the first reaction with the catalyst or attached to the catalyst to form intermediates, and then further reaction to produce products and catalysts, so the amount of catalyst in theory is the same! The activation of these two processes can be reduced! So there will be two peaks! Can be simplified as a peak!

- Q: describe a biological catalyst?

- One of the best known biological catalyst reactions is the Fixation of Nitrogen. Biological Nitrogen Fixation (BNF) occurs when atmospheric nitrogen is converted to ammonia by a bacterial enzyme called nitrogenase. Microorganisms that fix nitrogen are called diazotrophs. The formula for BNF is: N2 + 8H+ + 8e? + 16 ATP → 2NH3 + H2 + 16ADP + 16 Pi Although ammonia (NH3) is the direct product of this reaction, it is quickly ionized to ammonium (NH4+). In free-living diazotrophs, the nitrogenase-generated ammonium is assimilated into glutamate through the glutamine synthetase/glutamate synthase pathway.

- Q: Will the chemical catalyst not reduce that?

- Why is it done? Although the catalyst does not react chemically, the catalyst itself is deteriorated and is not always used

- Q: In the catalyst and light conditions to break down the water to get the chemical equation of hydrogen

- 2H2O = (light or catalyst) 2H2 ↑ + O2 ↑

- Q: The role of catalyst in chemical reactions

- The role of the catalyst is to change the reaction required to achieve the activation energy, can reduce the activation energy is called positive catalyst (that is, usually the meaning of the catalyst), to improve the activation energy is negative catalyst

- Q: What is the difference between biological enzymes and chemical catalysts?

- The biological enzyme is a class of molecules with moderate molecular weight in the living cells. It is a natural macromolecule catalyst in nature because the enzyme and the reactants are more specific than the reaction of the catalyst with the chemical synthesis of the catalyst (1) High efficiency (2) selectivity good by-product less (3) mild reaction conditions and so on

- Q: I was hoping to buy a land rover lr4 or lr2, but with the lr4 having gas mileage in the mid teens, i wanted to know if there is a way to improve it. I dont drive on the highway too much. I'd like to know if there is anything else to improve mileage too. I drive a lot of people around for functions, family, and others and I looked at other suvs but those two looked the best.

- Fuel catalyst is another name for fuel additive, the companies that make these additives make all kinds of claims how it increases power and reduces emiissions.. blah blah blah. Fuel catalyst is nothing more then a octane booster (gas engines) or cetane booster (diesel engines), it like all the other bogus products are worthless, octane booster will only show an improvement in performance IF the octane level in your current fuel supply is too low, higher octane fuel burns slower then lower octane fuel, that's how it quenches pinging and preignition both of which are caused by incorrect engine design and/or settings. Always use the lowest octane fuel that the engine will tolerate, if you have to pull advance out of the total timing then it needs more octane to run full timing and make max power, the only thing you can do to improve the quality of fuel in your tank is add a stabililizing additive such as (Stabil), it treats the fuel and prevents it from going stale or turning to varnish, it's especially useful when the vehicle is parked for long periods with fuel in the tank and carburetor, normally after a month or two of being parked the fuel in the carb turns to varnish and clogs the jets, with Stabil the fuel doesn't change composition.

- Q: Does anybody have any tips or references I can go to for this? I'm writing a novel and the main character wants to be a catalyst; the story isn't about him and his journey, so much as the effects on everyone around him that come about simply because of him being there and being who he is. How would I go about doing this, and doing it well?

- Ways to be a catalyst: By his behaviour: - He is a good listener. People use him as a sounding board and make important decisions as a result. - He is indiscreet and inadvertently reveals people's secrets and back-sniping comments. - He is a ****-stirring gossip. - He is a home-wrecking Lothario. - He is wise and gives good advice. - He is a hooligan who ruins businesses with vandalism, costs people their jobs and ruins relationships by beating people up. - He is a manipulative, blackmailing bastard who tries to turn every woman into a prostitute and con every man out of his money. - He is a charlatan who preaches nonsense about religion, health and business investments. By effortlessly influencing other people's behaviour: - He is famous and people try to impress him wherever he goes. - He has cancer or a disabling war wound. People admire and pity him and are shocked by his PTs mood wings. - He is gay, Muslim or a suspected paedophile and people want to persecute or cure him. - He is destitute. People argue amongst themselves over whether it's because he's lazy, has bad karma or there but for the grace of God go I. - He really looks like Jesus, Buddha or Santa and the sight of him makes people contemplate their Humanist values, coming to various conclusions. Perhaps you can write about his reputation; how he earned it, how it precedes him and provokes prejudices that he sometimes confirms or disproves. Use a detached, omniscient God-narrator. (Pretend Morgan Freeman's reading the audiobook.) Alternatively perhaps he is not a catalyst but a neurotic voyeur, fascinated by the minutiae of other people's lives so that the mundane appears tumultuous. He is not influencing people but your account of the changes in people's lives are centred on his observation of them.

- Q: In biology, the enzyme seems to be a tool for opening a reaction, such as the decomposition of cellulose, such as linked RNA and protein, no enzyme can not. But in chemistry, the catalyst is only a regulatory role, change the reaction rate only. The teacher said that the enzyme is the catalyst. Is there any other effect of the enzyme? (Ignorant high three dogs, you do not spray the big god)

- In fact, the chemical reaction is from the substrate (S) to the product (P). The chemical reaction is from the substrate (S) to the product (P). The chemical reaction is from the substrate (S) to the product (P) the process of. However, there is a free energy barrier between S and P, and in the absence of a catalyst, it is difficult to step through it and will pull something about it. Or understood to want you to jump 3 meters high, it is simply to life.

- Q: chemistry subject

- Catalyst is the substance used to enhance or reduce the speed of a reaction.. there are thousand of catalyst used..(product of one reaction may act as catalyst of another).. you can see in google

Send your message to us

Amino Trimethylene Phosphonic Acid Liquid And Solid

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches