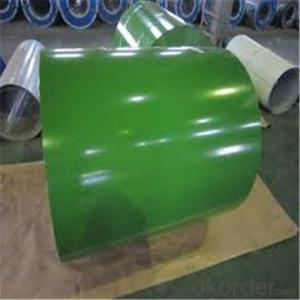

ALUZINC STEEL IN COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specification

1. Thickness: 0.3-0.8mm

2. Width: 914-1250mm

3. Inner Diameter: 508mm

4. Weight of Steel Coil: 3-15MT

5. Available Dipped Layer: 50-150g/m2

6. Surface Texture: Normal Coated

7. Type of coating structure: 2/1 Coat the top surface of the steel sheet twice, coat the bottom surface once, and bake the sheet twice.

8. Front side paint thickness: 15-25μm (bottome paint + top paint)

9. Back side paint thickness: 5-10μm

Mechanical Properties

1. Mechanical properties of base metals

Grade | Tensile Test | ||

Yield Strength MPa | Tensile Strength MPa | Elongation A80mm % ≥ | |

DC51D+AZ | 280-325 | 320-500 | 22 |

DC52D+AZ | 240-300 | 270-420 | 26 |

DC53D+AZ | 140-260 | 270-380 | 30 |

2. Common performance of front coating

(1). Thickness: ≥20μm

(2). Pencil Hardness: 2H

(3). 60° specular glossiness of coating: >60

(4). 180°bend: ≤3T

(5). Impact: ≥9J

(6). Salt Fog Resistant: ≥500h

(7). Color difference: <3ΔE

- Q: How do steel coils impact the environment?

- Steel coils impact the environment in several ways. Firstly, the production of steel coils requires large amounts of energy and resources, leading to increased greenhouse gas emissions and depletion of natural resources. Additionally, the manufacturing process generates air and water pollution, contributing to environmental degradation. Furthermore, the disposal of steel coils after use can result in land pollution if not properly managed. Overall, the production and use of steel coils have a significant environmental footprint.

- Q: How are steel coils inspected for surface quality?

- To ensure that steel coils meet the required standards and are defect-free, a meticulous inspection process is carried out using various methods and technologies. The following steps are involved in inspecting the surface quality of steel coils: 1. Visual Inspection: Trained personnel visually examine the entire surface of the coils to detect any visible defects such as scratches, dents, or irregularities. This step allows for the identification of obvious issues through visual observation. 2. Magnetic Particle Inspection: This non-destructive testing method involves applying a magnetic field to the surface of the steel coil and then adding a magnetic particle solution. Any surface cracks or defects cause the magnetic particles to cluster, making them visible under appropriate lighting. This technique effectively detects surface cracks and abnormalities. 3. Eddy Current Testing: Electromagnetic induction is used in this inspection method to identify surface defects. An eddy current probe is moved over the surface of the steel coil, and any variations in the electrical current induced by the magnetic field are detected. This technique is especially useful for detecting surface cracks, pits, or corrosion. 4. Ultrasonic Testing: Ultrasonic waves are employed to inspect the surface of the steel coil for hidden defects like subsurface cracks or inclusions. High-frequency sound waves are transmitted into the material, and any changes in the reflected sound wave pattern indicate the presence of defects. Ultrasonic testing is highly reliable and can detect even the smallest defects within the steel coil. 5. Surface Roughness Measurement: Specialized equipment is used to measure the surface roughness of the steel coil. This measurement helps determine if the surface meets the required smoothness standards. The equipment scans the surface and provides detailed information about the roughness, allowing the inspector to ensure it falls within an acceptable range. In summary, the inspection of steel coils for surface quality involves a comprehensive process that combines visual examination with advanced testing methods such as magnetic particle inspection, eddy current testing, ultrasonic testing, and surface roughness measurement. These inspection techniques effectively identify and evaluate potential defects or surface irregularities, ensuring that the steel coils meet the necessary surface quality standards.

- Q: How do steel coils contribute to fire resistance in buildings?

- Steel coils contribute to fire resistance in buildings by providing structural integrity and stability. The use of steel coils in construction helps in preventing the collapse of buildings during a fire. Steel, being a non-combustible material, does not contribute to the spread of fire, allowing occupants more time to evacuate safely. Moreover, steel coils have high melting points, which means they can withstand intense heat for a longer duration before losing their strength. This property helps in slowing down the fire's progression and gives firefighters more time to control the blaze.

- Q: How are steel coils used in the production of roofing materials?

- Steel coils are used in the production of roofing materials by being fed into a roll-forming machine, which shapes the coils into the desired profile for the roofing panel. The coils are then cut to the appropriate length, coated with protective finishes, and formed into individual roofing panels that are ready to be installed on buildings.

- Q: doesnt steel rust?

- ferrous metals rust

- Q: Well im currently doing a project. Wanna help me? Because trust me, i really need it. You know how steel was created in China? If you didnt, you just learned something newww(: but anyways got any info on that? Websites? or just info from websites? Well lemme know because if its the best you get Best Answer Easy points right? (: Okay thanksss (:

- Steel is created in a primitive way whenever iron oxide ore (red dirt) is mixed with wood and burned. Seemingly everyone has a pet theory how their own selected country was the first to notice and do it on purpose. Regards, Larry.

- Q: How are steel coils processed into finished products?

- Steel coils are processed into finished products through a series of steps that typically include uncoiling, leveling, cutting, and shaping. After uncoiling, the steel coils are passed through a leveling machine to remove any unevenness. Then, they are cut into specific sizes and shapes using different cutting techniques such as shearing or slitting. Finally, the cut steel pieces are shaped through various processes like bending, welding, and machining to produce the desired finished products.

- Q: I'm searching for the elastic modulus of ASTM A653 galvanized steel sheet. Max points for first person with a response that includes web address of reliable reference - I just haven't found it yet. thanks!

- I've okorder /

- Q: Does steel have a valence number and if so, what is it?

- Steel is a mixture, so it doesn't have any valence number. On the other hand, all of the components of the steel mixture are in their elemental forms, so all the various valences are zero.

- Q: I have taylormade burner steel irons and I was wondering what would the flex of steel be if you were to compare it to graphite shafts, like regular, stiff, super stiff, etc...THANKS!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- If i understand you correctly, i think you misunderstand shafts. Steel shafts vs. graphite shafts these days is more of a competition of weights, not flexibility. Both steel and Graphite have different flex profiles available from Ladies (L) to super stiff (X). Graphite may feel a little more whippy than steel because of the lighter weight. Shafts will vary by company as well. Stiff from True temper may not be as stiff as one from Aldila, or vice verse. You can also make a shaft play stiffer or more flexible by where you cut the length. This is called tipping. Take more from the bottom and it will be stiffer, more from the grip end and it will play more flexible.

Send your message to us

ALUZINC STEEL IN COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords