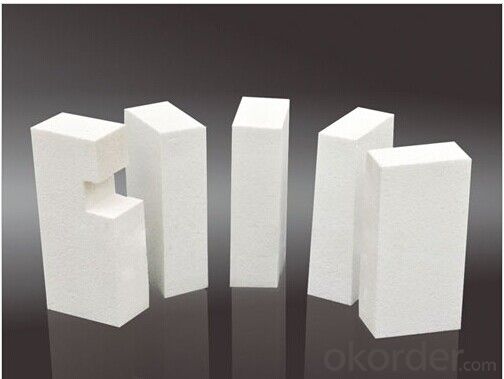

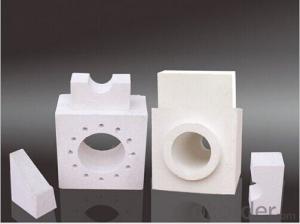

Alumuna Hollow Ball Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1. High temperature resistance.

2. Good thermal insulation.

3. Professional manufacturer.

Alumina hollow ball brick, Alumina bubble brick , Alumina hollow sphere brick , Hollow alumina sphere bricks

Alumina hollow ball brick used the alumina hollow ball,corundum powder,and calcined powders mixed at definite proportion as raw material. After mixing, drying, forming, firing at high temperature shuttle kiln made.

Physical and chemical index:

Item | ZYL-84 | ZYL-90 | ZYA-1.2 | ZYA-1.5 | ZYA-1.7 |

Al2O3 % ≥ | 84 | 90 | 98.5 | 98.5 | 98.5 |

Fe2O3 % ≤ | 0.8 | 0.5 | 0.3 | 0.3 | 0.3 |

SiO2 % ≤ | 15 | 9 | 1.0 | 1.0 | 1.0 |

Bulk density, g/m3,≤ | 1.5 | 1.5 | 1.2 | 1.5 | 1.7 |

Porosity,%, ≥ | 58 | 60 | 62 | 60 | 58 |

CCS,Mpa, ≥ | 16 | 15 | 3 | 12 | 15 |

Thermal conductivity, 1000°C,( W/m.k )≤ | 1.2 | 1.15 | 0.95 | 1.05 | 1.15 |

0.1Mpa RUL,°C ≥ | 1650 | 1700 | 1700 | 1700 | 1700 |

Refractoriness,°C ≥ | 1800 | 1800 | 1800 | 1800 | 1800 |

Characteristic:

1. High temperature resistance.

2. Low thermal conductivity.

3. Good thermal insulation.

4. High strength.

5. Can direct contact with flame.

6. Good chemical stability (acid-base erosion resistance ).

7. Low bulk density (lighter than the same kind of material ,thin kiln wall, low cost ) .

- Q: What industries commonly use insulating fire bricks?

- Insulating fire bricks are commonly used in various industries where high temperature insulation is required. Some of the industries that commonly use insulating fire bricks include: 1. Steel industry: Insulating fire bricks are used to line the furnaces, kilns, and other high-temperature equipment in steel manufacturing plants. They provide excellent insulation, reducing heat loss and improving energy efficiency. 2. Glass industry: In glass manufacturing facilities, insulating fire bricks are used to line the furnaces and ovens where the glass is melted and molded. These bricks help maintain high temperatures while minimizing heat loss, ensuring efficient and consistent production. 3. Ceramic industry: Insulating fire bricks are used in ceramic kilns and pottery ovens, providing thermal insulation to maintain the desired temperature for clay and ceramic products. They help conserve energy and optimize firing processes. 4. Cement industry: Cement kilns require high-temperature insulation to efficiently produce cement. Insulating fire bricks are used to line the kilns, reducing heat loss and improving thermal efficiency. 5. Foundry industry: Insulating fire bricks are used in foundries to line the melting furnaces and ovens used for metal casting. They help retain heat, ensuring consistent and efficient melting of metals. 6. Power generation industry: Insulating fire bricks are used in boilers, furnaces, and incinerators in power plants. These bricks provide thermal insulation, preventing heat loss and improving the overall efficiency of power generation processes. 7. Petrochemical industry: In refineries and chemical processing plants, insulating fire bricks are used to line equipment such as reactors, furnaces, and ovens. They provide insulation to withstand high temperatures and harsh chemical environments. 8. Pharmaceutical industry: Insulating fire bricks are used in pharmaceutical manufacturing facilities to line the ovens and dryers used for various processes. These bricks ensure precise temperature control and energy efficiency. Overall, insulating fire bricks find applications in industries where high-temperature insulation is crucial for efficient and cost-effective operations.

- Q: Can insulating fire bricks be used in metal melting furnaces?

- Yes, insulating fire bricks can be used in metal melting furnaces. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation, making them an ideal choice for applications like metal melting furnaces. These bricks have low thermal conductivity, which helps to retain heat and reduce energy consumption. Additionally, insulating fire bricks are lightweight, durable, and resistant to thermal shock, making them suitable for the extreme conditions encountered in metal melting furnaces.

- Q: Are insulating fire bricks suitable for use in coke ovens?

- Insulating fire bricks are not suitable for use in coke ovens. Coke ovens require bricks that can withstand extremely high temperatures and harsh chemical environments. Insulating fire bricks are designed to provide thermal insulation and are not able to withstand the heat and chemical exposure that occurs in coke ovens. Therefore, it is crucial to use refractory bricks specifically designed for coke ovens, which have high resistance to temperature, chemical attacks, and thermal shock. These refractory bricks are typically made from materials such as silica, alumina, and carbon, which can withstand the harsh conditions inside the coke ovens.

- Q: Can insulating fire bricks be used for insulation in aluminum smelters?

- Yes, insulating fire bricks can be used for insulation in aluminum smelters. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for use in aluminum smelters where extreme heat is generated.

- Q: Are insulating fire bricks resistant to impact or mechanical stress?

- Yes, insulating fire bricks are resistant to impact and mechanical stress. Insulating fire bricks are made from lightweight refractory materials that are designed to withstand high temperatures and thermal shock. These bricks are specifically engineered to have a high resistance to mechanical stress and impact, making them suitable for various applications where they may be subjected to external forces or pressure. Their structural integrity and durability allow them to maintain their shape and thermal insulation properties even when exposed to mechanical stress or impact, making them an ideal choice for use in furnaces, kilns, and other high-temperature environments.

- Q: Can insulating fire bricks be used in contact with molten metal?

- Indeed, it is possible to utilize insulating fire bricks in direct contact with molten metal. Specifically engineered to endure extreme temperatures, these bricks are widely employed in industrial settings where they encounter molten metal. With their exceptional resistance to thermal shock, they are capable of withstanding the intense heat generated by molten metal. Furthermore, insulating fire bricks possess low thermal conductivity, thereby reducing heat loss and enhancing energy efficiency. However, it is crucial to ascertain that the specific variant of insulating fire brick employed is suitable for the specific type of molten metal and temperature range it will be exposed to. Different metals possess varying melting points, which may necessitate the use of more specialized refractory materials.

- Q: Are insulating fire bricks suitable for commercial or industrial applications?

- Insulating fire bricks are an ideal choice for commercial and industrial use. These bricks are specifically designed to withstand high temperatures and provide exceptional thermal insulation. They are commonly used in industries such as steel, cement, glass, and ceramics. In commercial settings, insulating fire bricks are frequently employed in kilns, furnaces, and ovens to ensure heat retention and energy efficiency. They help minimize heat loss, resulting in lower fuel consumption and cost savings for businesses. Additionally, their lightweight nature facilitates easy handling and installation, which is advantageous in time-sensitive commercial environments. In industrial applications, insulating fire bricks play a critical role in maintaining desired temperatures in industrial furnaces, reactors, and boilers. These bricks can endure extremely high temperatures, making them suitable for harsh industrial conditions. They also exhibit excellent resistance to thermal shock, preventing cracking or breaking when exposed to rapid temperature changes. Moreover, insulating fire bricks provide effective insulation against heat transfer, enhancing the overall efficiency of industrial processes. By reducing heat loss, they contribute to energy conservation and lower operating costs. Additionally, their durability and ability to withstand the demands of industrial operations make them a reliable choice for long-term use. In conclusion, insulating fire bricks are highly suitable for both commercial and industrial applications. Their exceptional thermal insulation properties, resistance to high temperatures, and durability make them the preferred choice in industries where heat retention, energy efficiency, and cost-effectiveness are of utmost importance.

- Q: Can insulating fire bricks be cut or shaped to fit different spaces?

- Yes, insulating fire bricks can be cut or shaped to fit different spaces. They are typically made from a soft, lightweight material that can be easily cut or shaped using common tools like saws or knives. This flexibility allows for customization and adaptation to various spaces and applications.

- Q: What is the thermal insulation performance of aerated bricks?

- Aerated brick light weight, heat preservation, heat insulation, sound insulation, easy processing, using a variety of hybrid material production, rich production of raw materials, especially the use of fly ash, and comprehensive utilization of industrial waste, environmental pollution, saving farmland, have a good social and economic benefits, is an alternative to the traditional solid clay brick ideal wall materials. Gongyi Machinery Factory is specialized in producing aerated brick equipment manufacturers.

- Q: Are insulating fire bricks resistant to alkali vapor attack?

- Yes, insulating fire bricks are generally resistant to alkali vapor attack. They have a high degree of chemical stability and can withstand exposure to alkali vapors without significant degradation or damage.

Send your message to us

Alumuna Hollow Ball Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords