Aluminum Sheets Virginia - Cold Rolled Steel Sheets Wholesale from China Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Cold Rolled Steel Sheets Wholesale from China Factory

Name | galvanized steel coil dx52d z gi |

Grade | GB/T-12754: 2006, JIS3302, EN 10142, ASTM A653, JIS G3302, SGCC/SGCH, GB/T2518, European Standard, ASTM A792, JIS G3321, JIS G3317 |

BASE PLATE | Cold rolled steel sheet, hot dipped zinc coated steel sheet hot dipped A-Z coated steel sheet |

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

ZINC COATING | 40g-275g /m2 |

PAINT THICKNESS | Top:20+-5um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

BASE SHEET | Cold rolled steel sheet, hot dipped zinc coated steel sheet (small, regular or zero spangle), hot dipped A-Z coated steel sheet |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Cold Rolled Steel Sheets Wholesale from China Factory

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Cold Rolled Steel Sheets Wholesale from China Factory

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

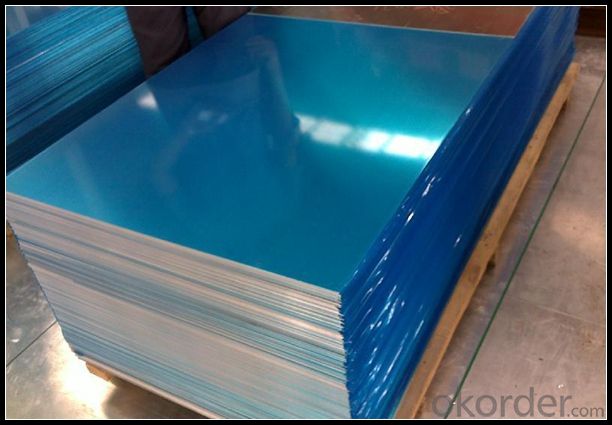

5. Image of Cold Rolled Steel Sheets Wholesale from China Factory

6. Package and shipping of Cold Rolled Steel Sheets Wholesale from China Factory

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be used for air conditioning systems?

- Yes, aluminum sheets can be used for air conditioning systems. Aluminum is a popular material choice for air conditioning components due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion. It is commonly used for manufacturing air conditioner coils, fins, and heat exchangers.

- Q: I have heard that drinking from aluminum cans is bad for our health. However, I have learned that today's 'aluminum' cans are actually more like a plastic can due to all the coatings, etc. Do we really have any risks associated with regular cans?

- This Site Might Help You. RE: Are today's aluminum cans bad for our health? I have heard that drinking from aluminum cans is bad for our health. However, I have learned that today's 'aluminum' cans are actually more like a plastic can due to all the coatings, etc. Do we really have any risks associated with regular cans?

- Q: Can aluminum sheets be anodized in different colors?

- Aluminum sheets have the capability to undergo anodization in various colors. Anodization involves an electrochemical procedure that enhances the natural oxide layer on the surface of aluminum. By submerging the aluminum sheet in an electrolyte bath and applying an electric current, a controlled oxidation process takes place, resulting in a thick and long-lasting oxide layer on the surface. Throughout the anodization process, different dyes can be introduced into the electrolyte bath, enabling the aluminum to absorb the dye particles and generate a colored oxide layer. This allows for a wide array of colors to be achieved, including red, blue, green, yellow, and numerous others. Furthermore, the brightness and tone of the color can be regulated by adjusting factors such as the dye concentration and the voltage applied during anodization. The anodized layer that forms on the aluminum sheet not only offers a vibrant and visually appealing appearance but also enhances its resistance to corrosion and durability. This makes anodized aluminum sheets an exceptional choice for architectural, decorative, and industrial applications where customization of color is desired while retaining the inherent advantages of aluminum.

- Q: Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100.Should I take it? Or just stick with my steel ones?

- Aluminum rims are a whole lot better on the mechanical stand point, they are lighter, usually stronger (depending on the alloy) and they allow for better heat disapation. Lighter rims will save gas money (nothing you will notice, maybe an extra mile/tank, if that). Depending on the alloy used in the aluminum rims, they are usually stronger and can take more froce abuse, just as long as they don't get scuffed up, ect. With the better heat disapation. When the brakes heat up, the heat is sent out ever direction, mostly through metal. Aluminum (alloy) is a great conductor of heat. So when the brakes heat up, the aluminum rims will absord much of this heat, and the outside air will be able to cool the rim faster then the brakes themselves, but the brakes will stay cooler this way. Brakes that are running cooler, will last longer then brakes running hot. You will have less of a chance of brake fade a condition where the brakes get to a point of being to hot, they don't function at all, or its hard to stop the vehicle. It will also extend the brakes over all life, in some cases up to 40-50%. I had stock steel rims in my truck, small rims for a small truck, and whenever I was doing highway driving, i would get brake fade under high speed braking. When I switched to aluminum rims, I have not had brake fade since, I don't know about the life on the pads, as I switched the rims, before I wore a set down. I picked up a set of 4 5spoke rims from an Explorer and put them on my ranger, I paid $80 for the 4 and they look in pretty good shape, little corrosion. A down side to aluminum rims is corrosion, they corrode easier, and can cuase discolouration of the rim itself, or can cause leaky tires if it corrodes around the bead seat, which it usually does. Its a fair trade off however.

- Q: How do aluminum sheets compare to other metals?

- Aluminum sheets have several advantages compared to other metals. Firstly, they are lightweight, making them more manageable and cost-effective for transportation and installation. Secondly, aluminum has excellent corrosion resistance, allowing it to withstand harsh environments without deteriorating. Additionally, aluminum sheets are highly malleable, making them easy to shape and form into various designs. Lastly, aluminum exhibits good thermal and electrical conductivity, making it suitable for applications requiring heat dissipation or electrical conductivity. Overall, aluminum sheets offer a unique combination of properties that make them a versatile choice among other metals.

- Q: Can aluminum sheets be used for railway carriages?

- Yes, aluminum sheets can be used for railway carriages. Aluminum offers several advantages for this application. Firstly, it is lightweight, which helps reduce the overall weight of the carriage, leading to improved fuel efficiency and lower operating costs. Additionally, aluminum has a high strength-to-weight ratio, making it durable and resistant to corrosion. This is particularly beneficial for railway carriages, as they are exposed to various weather conditions and need to withstand long-term use. Furthermore, aluminum is easily formable, allowing for complex shapes and designs in the carriage structure. Lastly, aluminum is a highly recyclable material, aligning with the increasing focus on sustainability in the transportation industry. Overall, the use of aluminum sheets in railway carriages provides numerous advantages in terms of weight, strength, durability, and environmental sustainability.

- Q: I am trying to find a BRUSH ON type glue to adhere aluminium foil to a plastic model. scotch super 77 works great but dries way to fast and blows small pieces all over. white glue just dont work and superglue eats the plastic. I could use some help

- Gluing Aluminum

- Q: Can aluminum sheets be used in aerospace industries?

- Yes, aluminum sheets can be used in aerospace industries. Aluminum is commonly used in the aerospace industry due to its lightweight, high strength-to-weight ratio, and corrosion resistance properties. It is used for various applications such as aircraft structures, wings, fuselages, and skins.

- Q: How do you clean aluminum sheets?

- To clean aluminum sheets, you can follow a few simple steps: 1. Start by removing any loose dirt or debris from the surface of the aluminum sheet. You can use a soft brush or cloth to gently sweep away any particles. 2. Prepare a cleaning solution by mixing a mild detergent or dish soap with warm water. Avoid using strong chemicals or abrasive cleaners as they can damage the aluminum. 3. Dip a soft cloth or sponge into the cleaning solution and gently scrub the aluminum sheet. Make sure to cover the entire surface, paying extra attention to any stains or spots. 4. If there are stubborn stains or marks on the aluminum, you can use a non-abrasive cleaner specifically designed for aluminum. Apply the cleaner to a soft cloth and rub gently on the affected area until the stain is removed. 5. Rinse the aluminum sheet thoroughly with clean water to remove any soap residue. This step is essential to prevent any build-up or streaks on the surface. 6. Dry the aluminum sheet completely using a soft towel or cloth. Make sure there is no moisture left as it can cause water spots or corrosion over time. 7. For added shine and protection, you can apply a thin layer of aluminum polish or wax. This will help to restore the luster and protect the aluminum from future tarnish or oxidation. It is important to note that the cleaning method may vary depending on the type of dirt or oxidation on the aluminum sheet. Always read and follow the manufacturer's instructions for specific cleaning recommendations.

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into diluted hydrochloric acid?

- Aluminum element is extremely activated and will react with oxygen, generating aluminum oxide, once being exposed in air, so there is a layer of aluminum oxide on the surface of daily aluminum products including aluminum sheet. When aluminum sheet is put into diluted hydrochloric acid, aluminum oxide on the surface will firstly react with hydrochloric acid, generating aluminium chloride and water, the process won’t generate bubble, but after finishing the reaction of aluminum oxide on the surface, when the exposed aluminum element reacts with hydrochloric acid, generating aluminium chloride and oxygen, the bubble appears.

Send your message to us

Aluminum Sheets Virginia - Cold Rolled Steel Sheets Wholesale from China Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords