Aluminum Sheets Hawaii - Color Coated Aluminium Coils Polyester Coating AA3004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

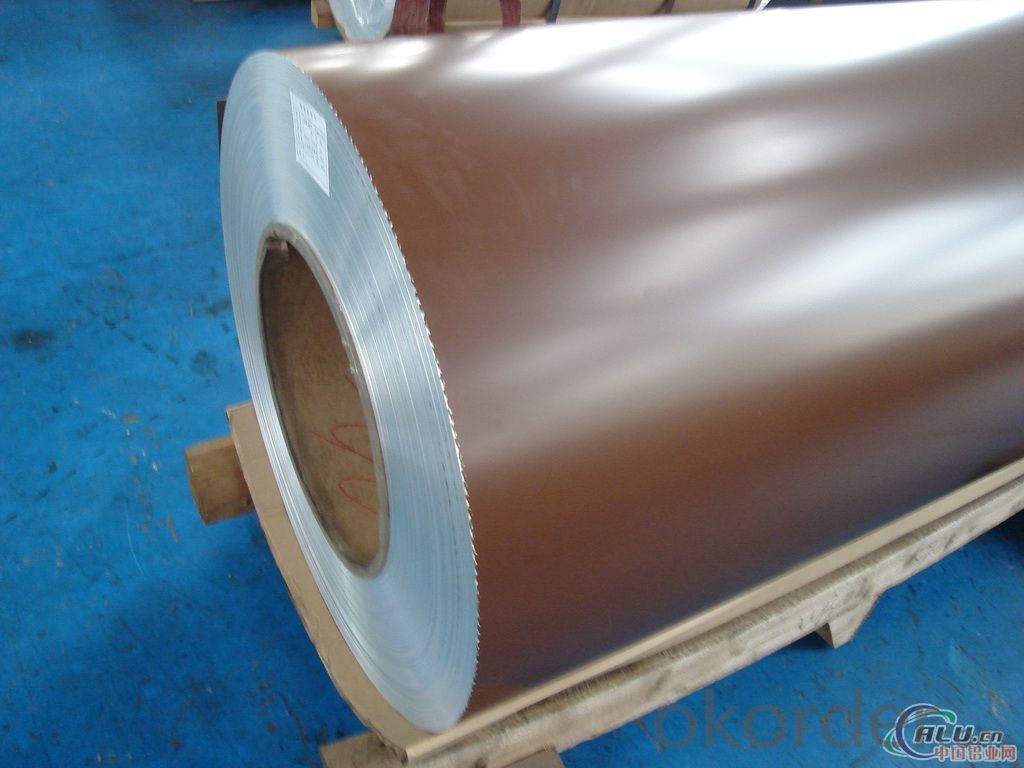

1.Structure of Color Coated Aluminium Coils

PE Coated aluminium coils are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Color Coated Aluminium Coils

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2mm-3mm | 1200MM-1800MM | Min 5 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: why could aluminum pot be repaired by knocking the aluminum sheet into the pot but not being bonded by glue?

- the oxidation rate of aluminum's surface is very quick, so we cann't use the method of tin welding, and the cost of argon arc welding is very high,so aluminum pot's repair usually uses riveting. aluminum has low hardness and good ductility, so it can be repaired by tightly knocking, without the bonding of glue. general glue will decomposed in open fire, if we bond pot by glue, the pot after repair won't be able to endure high temperature.

- Q: Are aluminum sheets suitable for food processing equipment?

- Yes, aluminum sheets are suitable for food processing equipment. Aluminum is a widely used material in the food processing industry due to its excellent properties. It is corrosion-resistant, lightweight, and has good thermal conductivity, making it ideal for applications where hygiene and efficient heat transfer are crucial. Additionally, aluminum is non-toxic and does not react with food, ensuring that it does not affect the taste or quality of the processed products. Overall, aluminum sheets are a popular choice for food processing equipment as they meet the necessary safety and performance requirements.

- Q: Are aluminum sheets suitable for furniture manufacturing?

- Indeed, furniture manufacturing can make effective use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers a multitude of advantages for the production of furniture. It possesses corrosion resistance, rendering it suitable for both indoor and outdoor furniture. Moreover, aluminum showcases a remarkable strength-to-weight ratio, facilitating the creation of robust and long-lasting furniture items. Additionally, aluminum proves to be easily malleable, as it can be cut, bent, and welded into various shapes and designs. Furthermore, aluminum can be treated with a diverse range of coatings or paints to enhance its visual appeal and safeguard it from damage. In summary, the strength, versatility, and aesthetic allure of aluminum sheets establish them as a viable alternative for furniture manufacturing.

- Q: Which kind of glue can bond hard shell plastic and iron sheet or aluminum sheet?

- You can use 502, Alteco and other instant glue to bond plastic and metal, chloroprene rubber adhesive or glass cement are also ok.

- Q: How to clean the aluminium oxide on the surface of aluminum? What kind of materials should we use to clean the thin aluminum sheet, and what's the concentration?

- You can sprinkle the mix of Alkaline water,vinegar,washing powder and liquid detergent on the surface. And after a period of time, rub it with soft silk, after it being dry,sprinkle again and rub until it's clean.

- Q: What oil does the aluminum plate stretch with?

- There are professional tensile oil, you can ask to pull the rice cooker liner manufacturers know, if not a lot of production, you can use peanut oil first try, the effect barely enough!

- Q: Are aluminum sheets suitable for electrical connectors?

- Yes, aluminum sheets are suitable for electrical connectors. Aluminum is a highly conductive metal, which makes it an excellent choice for transferring electric current. It has a low electrical resistance, allowing for efficient transmission of electricity. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a popular material for electrical connectors in various industries such as automotive, aerospace, and electronics. However, it is important to note that aluminum connectors may require additional measures to prevent galvanic corrosion when used with dissimilar metals.

- Q: Are the aluminum sheets suitable for manufacturing chemical storage cabinets?

- Yes, aluminum sheets are suitable for manufacturing chemical storage cabinets. Aluminum is a strong and durable material that is resistant to corrosion, making it ideal for storing and protecting chemicals. It is also lightweight, which makes transportation and installation easier. Additionally, aluminum is non-reactive with most chemicals, ensuring the safety of the stored substances. Overall, aluminum sheets provide a reliable and efficient solution for manufacturing chemical storage cabinets.

- Q: How do you clean aluminum sheets?

- Achieving cleanliness for aluminum sheets involves a few straightforward steps: 1. Initiate the process by eliminating any loose dirt or debris from the aluminum sheet's surface. Use a soft brush or cloth to gently sweep away any particles. 2. Create a cleaning solution by combining warm water with a mild detergent or dish soap. It is crucial to avoid strong chemicals or abrasive cleaners since they can harm the aluminum. 3. Submerge a soft cloth or sponge into the cleaning solution and delicately scrub the aluminum sheet. Ensure that the entire surface is covered, giving extra attention to any stains or spots. 4. In the case of persistent stains or marks, utilize a non-abrasive cleaner specifically designed for aluminum. Apply the cleaner onto a soft cloth and gently rub it onto the affected area until the stain is eliminated. 5. Thoroughly rinse the aluminum sheet with clean water to eliminate any soap residue. This step is vital to prevent the accumulation of residue or streaks on the surface. 6. Dry the aluminum sheet completely using a soft towel or cloth. Verify that there is no remaining moisture as it can lead to water spots or corrosion over time. 7. To enhance shine and provide protection, apply a thin layer of aluminum polish or wax. This procedure aids in restoring the luster and safeguarding the aluminum from future tarnish or oxidation. It is important to acknowledge that the cleaning technique may differ based on the type of dirt or oxidation present on the aluminum sheet. Always refer to and adhere to the manufacturer's instructions for specific cleaning recommendations.

- Q: Can the aluminum sheets be used for manufacturing decorative trim?

- Indeed, the utilization of aluminum sheets is viable for the production of decorative trim. Being a versatile substance, aluminum is renowned for its lightweight nature, durability, and exceptional resistance to corrosion. It bestows the convenience of effortless shaping and molding into diverse decorative configurations and motifs. Furthermore, aluminum's aesthetic allure can be accentuated by applying coatings or paints of assorted hues. Consequently, aluminum sheets emerge as a highly favored option for fabricating decorative trim across a multitude of sectors, encompassing architecture, automotive, and interior design.

Send your message to us

Aluminum Sheets Hawaii - Color Coated Aluminium Coils Polyester Coating AA3004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords