Aluminum Sheets for Sale Mercer County - 2024 5052 5083 6061 7075 Aluminium Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium Reflective sheet

Alloy or No.: Alloy

Alloy No.: AA6061, AA6063

Thickness: 0.2-3mm

Width: 10mm-2200mm

Length:10mm-2200mm

Tensile strength: ≥140N/mm2

Elongation: ≥2%(H26)

Yield Strength: ≥120N/mm2

Usage: Lights, grille lamp, tunnel lamp, solar collector etc.

6061 aluminium sheet,aluminium price per kg Properties and composition

Typical Mechanical Properties of Aluminum | ||||

Aluminum grade and its state | Ultimate Tensile Strength (25°CMPa) | Tensile Yield Strength (25°CMPa) | Hardness 500kg force 10mm ball | Elongation 1.6mm(1/16in)thickness |

2024-T351 | 470 | 325 | 120 | 20 |

5052-H112 | 230 | 195 | 60 | 10 |

5083-H112 | 180 | 211 | 65 | 14 |

6061-T651 | 310 | 276 | 95 | 12 |

7050-T7451 | 510 | 455 | 135 | 10 |

7075-T651 | 572 | 503 | 150 | 11 |

Typical Physical Properties of Aluminum | |||||

Aluminum grade and its state | Average Coefficident of Thermal Expansion (20-100 °C)μm/M-K | Approximate Melting range (°C) | Electrical Conductivity 20 °C(68°F)(%IACS) | Elecytrical Resistivity 20 °C(68°F) Ωmm²/m | Density (20 °C)(g/cm³) |

2024-T351 | 23.2 | 500-635 | 30 | 0.058 | 2.82 |

5052-H112 | 23.8 | 607-650 | 30-40 | 0.050 | 2.68 |

5083-H112 | 23.4 | 570-640 | 29 | 0.059 | 2.72 |

6061-T651 | 23.6 | 580-650 | 43 | 0.040 | 2.73 |

7050-T7451 | 23.5 | 490-630 | 41 | 0.0415 | 2.82 |

7075-T651 | 23.6 | 475-635 | 33 | 0.0515 | 2.82 |

Chemical Composition Limit of Aluminum | |||||||||||

Aluminum grade | Si | Fe | Cu | Mn | Cr | Mg | Zn | Ti | Other | Al | |

each | total | Min | |||||||||

2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 0.1 | 1.2-1.8 | 0.25 | 0.15 | 0.05 | 0.15 | remaining |

5052 | 0.25 | 0.4 | 0.1 | 0.1 | 0.15-0.35 | 2.2-2.8 | 0.1 | - | 0.05 | 0.15 | remaining |

5083 | ≤0.40 | 0.4 | 0.1 | 0.3-1.0 | 0.05-0.25 | 4.0-4.9 | 0.25 | 0.15 | 0.05 | 0.15 | remaining |

6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.04-0.35 | 0.8-1.2 | 0.25 | 0.15 | 0.05 | 0.15 | remaining |

7050 | ≤0.12 | 0.15 | 2.0-2.6 | 0.1 | 0.04 | 1.9-2.6 | 5.7-6.7 | 0.06 | 0.05 | 0.15 | remaining |

7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 0.18-0.28 | 2.1-2.9 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | remaining |

- Q: Which kind of solution should I use while welding aluminum sheet and copper pipe by tin soldering?

- 1, you must use over 350W soldering iron, 2,prepare some borax and tin soldering paster, you can’t use rosin to weld it, 3, polish the pipe to clean with fine abrasive paper and borax, 4, put the pipe and sheet into borax, use the soldering trip to rub on the weldment with some borax. 5, after the pipe and sheet become hot, use the soldering iron with the paster and tin to rub the pipe and sheet in borax, then it can be welded. 6, they can be welded together after welding.

- Q: Remember the notorious Chevy Vega of the 1970's? As I recall,one the big problems with that car was that it was equipped with an aluminum block engine. The new Ford Mustangs arealso equipped with aluminum engines to reduce curb weightand improve fuel efficiency. Will they be prone to the sameproblems that the Vega had down the road? Are there othermanufacturers that have used aluminum engines with successrecently?

- This Site Might Help You. RE: how reliable are today's aluminum block engines? Remember the notorious Chevy Vega of the 1970's? As I recall, one the big problems with that car was that it was equipped with an aluminum block engine. The new Ford Mustangs are also equipped with aluminum engines to reduce curb weight and improve fuel efficiency. Will they be prone to...

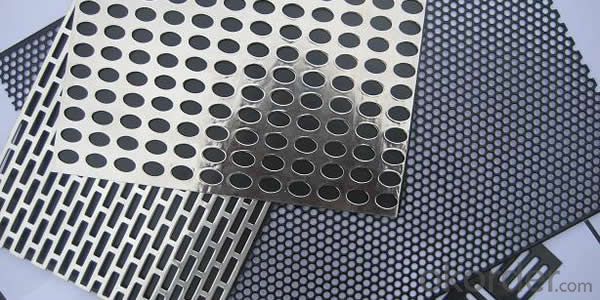

- Q: Are 101 aluminum sheets suitable for interior design or architectural applications?

- Yes, 101 aluminum sheets are suitable for interior design or architectural applications. They are commonly used due to their lightweight nature, durability, and corrosion resistance. Additionally, they can be easily formed into various shapes and sizes, making them versatile for different design purposes.

- Q: What is the weight of an aluminum sheet?

- The weight of an aluminum sheet can vary depending on its thickness and dimensions.

- Q: What kind of aluminum sheet is most suitable for constructing the exterior walls of a building?

- <p>The best type of aluminum sheet for building exterior walls is typically aluminum composite material (ACM) or aluminum coil coated with a protective layer. ACM is lightweight, durable, and offers excellent resistance to weather and corrosion. It also provides good thermal insulation and is easy to install. Coated aluminum coils are often used for cladding due to their strength, low maintenance, and longevity. The choice may also depend on specific project requirements, such as aesthetic considerations, budget, and local climate conditions.</p>

- Q: Are aluminum sheets suitable for architectural applications?

- Architectural applications can indeed benefit from the suitability of aluminum sheets. Aluminum, being a versatile material, offers numerous advantages for architectural projects. It possesses a lightweight quality while still being strong, making it easy to handle and install. Furthermore, its resistance to corrosion makes it ideal for outdoor applications that are exposed to the elements. The malleability of aluminum sheets allows them to be easily formed into different shapes and sizes, enabling architects to create innovative and creative designs. These sheets find their use in various architectural applications such as cladding, roofing, facades, as well as interior elements including ceilings, partitions, and decorative components. Moreover, architects have the freedom to choose from a wide range of finishes for aluminum sheets, including anodized, painted, or coated. These finishes not only enhance the aesthetics of the projects but also improve the material's durability and color retention, thereby ensuring long-term performance and minimal maintenance requirements. Beyond these advantages, aluminum is also a sustainable material. It is fully recyclable and has a lower carbon footprint compared to other metals. This aligns with the growing emphasis on environmentally-friendly construction practices in the architectural industry. In conclusion, due to their lightweight nature, strength, corrosion resistance, versatility, range of finishes, and sustainable attributes, aluminum sheets are highly suitable for architectural applications. Architects can confidently incorporate aluminum sheets into their designs, resulting in visually appealing and durable structures.

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: Can aluminum sheets be used for food packaging?

- Yes, aluminum sheets can be used for food packaging. Aluminum is a safe and widely used material in the food industry due to its excellent barrier properties, resistance to moisture, and ability to maintain product freshness.

- Q: Does it make any difference shiny side up, shiny side down when it comes to cooking with aluminum foil?

- I usually have the shiny side on the outside when I'm wrapping hot banana bread. I don't know why I do, I just do

- Q: Can aluminum sheets be welded or joined together?

- Yes, aluminum sheets can be welded or joined together. Aluminum is a highly weldable material and can be joined using various welding techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and laser welding. These techniques utilize heat to melt the aluminum sheets and create a strong bond. Additionally, aluminum sheets can also be joined using mechanical fasteners like screws, rivets, or adhesive bonding. The choice of welding or joining method depends on the specific application and desired outcome.

Send your message to us

Aluminum Sheets for Sale Mercer County - 2024 5052 5083 6061 7075 Aluminium Sheet from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords