Aluminum Sheets for Sale Brisbane - Competitive Price Aluminum Sheet for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications of Aluminium Sheet

Alloy | Thickness(mm) | Width(mm) | Length(mm) | Temper | DC or CC | |

1050,1060,1070,1100, 1235 | 0.2-3.0 | 300-1850 | 1000-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

3.0-150 | 900-1900 | H112,H111 | DC | |||

3003,3004,3105,3005 | 0.2-3.0 | 300-1850 | 1000-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

3.0-150 | 900-1900 | H112,H111 | DC | |||

5052,5083,5754,5005 | 0.2-3.0 | 300-1850 | 1000-8000 | O,H12,H22,H14,H24,H16,H26,H18,H32,H36 | DC | |

3.0-150 | 900-1900 | H112, H111 | DC | |||

6061,6063 | 0.5-3.0 | 300-1500 | 1000-6000 | T6,T321 | DC, | |

width and length:to cut as your requirement thickness:0.15-0.3m Tensile Strength:130~150MPa .Yield Strength:130-145.Elongation:≥2%,Earing Rate:≤2%.There are no stop marks or pinch marks on the surface of aluminum sheets.

There are no water stains or blisters on the surface.

Mainly in Construction, decoration, PCB materials, cover material, LCD back panel, refrigeration, air conditioner, automobile, etc

The Main Features of Aluminium Sheet:

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

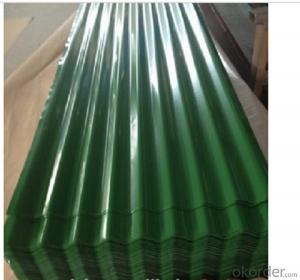

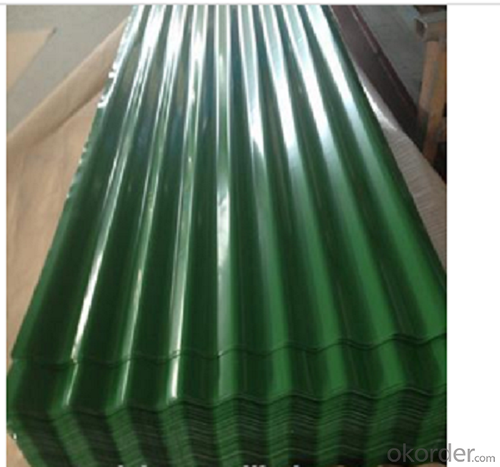

The Images of Aluminium Sheet:

FAQ:

1. Minimum Order Quantity? MOQ is 25 tons, your quantity is ok, the aluminium foil sample is available. |

2. What kind of terms of payment? T/T, L/C,D/A,D/P,Western Union are available. |

3. What grams of the product can you offer? Our products can be customized according to your requirment |

4.Can you do Customization & Reproduction if I provide a photo? Yes, we do Customization & Reproduction service, please check the details and sample above. You need to send the pictures to our email, tell us the specification you want, then we will quote you exact price. We will take photos for you check. |

5. Does the packaging safe and arrive in good conditions? Yes, Safe Packing guarrantee, all the products will arrive your door under good conditions. We response to problem of shipping if there unfortunately is. |

6. How long does it usually take to deliver the product? We'll make the shipment to you immediately. It will take about 18 to 40 days arrive worldwide. Accurate delivery time depends on the specific quantity |

7.Is drop shipping abailable? Yes, it is, we can send to worldwide. |

- Q: This question asks about the various colors and finishes that can be applied to aluminum sheets.

- <p>Aluminum sheets are available in a wide range of colors and finishes, offering versatility for various applications. Common colors include silver, white, black, and bronze, but they can also be anodized or painted to achieve virtually any color. Finishes can be smooth, brushed, or embossed, with options like matte, satin, and gloss. Additionally, there are specialty finishes like mirror-like polished, hammered, and wood grain textures. The choice of color and finish depends on the specific requirements of the project, such as aesthetics, durability, and resistance to environmental factors.</p>

- Q: why can't aluminum sheet burn after polishing?

- because aluminum will rapidly formulate dense oxide film once being exposed in air, oxide film will generate after polishing, it can't burn.

- Q: Are aluminum sheets resistant to UV radiation?

- Yes, aluminum sheets are generally resistant to UV radiation. Aluminum is known for its excellent corrosion resistance, and this extends to its resistance to UV radiation as well. The oxide layer that naturally forms on the surface of aluminum provides a protective barrier against the harmful effects of UV rays. This oxide layer acts as a shield, preventing the aluminum from deteriorating or fading when exposed to sunlight or other sources of UV radiation. However, it is important to note that prolonged exposure to intense UV radiation may eventually cause some degradation or discoloration of the aluminum surface. Therefore, while aluminum sheets are highly resistant to UV radiation, it is still advisable to provide additional protection, such as coatings or paint, for applications that require extended exposure to harsh UV environments.

- Q: Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100.Should I take it? Or just stick with my steel ones?

- This Site Might Help You. RE: Steel or aluminum alloy rims? Which are better? I currently have steel (kinda ugly) rims on my Chevy Blazer right now, and my roommate has some aluminum alloy rims that will fit that he wants to sell me. He hates my steel rims so much that he's willing to sell me the alloy ones for $100. Should I take it? Or just stick...

- Q: What are the fire-resistant properties of aluminum sheets?

- Aluminum sheets possess remarkable fire-resistant properties, making them an excellent choice for various applications where fire safety is a concern. The primary reason for their fire resistance is the unique oxide layer that forms naturally on the surface of the aluminum when exposed to oxygen. This layer acts as a protective barrier, preventing the metal from further oxidation and reducing the potential for combustion. The oxide layer on aluminum sheets is not only highly stable but also has a high melting point. This means that it can withstand high temperatures without melting or igniting, making it resistant to flames. Furthermore, the oxide layer is an effective thermal insulator, which helps to slow down heat transfer and prevent the spread of fire. Another advantage of aluminum sheets is their low flammability. Aluminum is a non-combustible material, meaning that it does not burn or support combustion. This property is particularly beneficial in situations where fire containment and prevention are crucial. Moreover, aluminum sheets have excellent heat dissipation capabilities. They quickly dissipate heat away from the source, minimizing the risk of overheating and potential fire hazards. This makes them suitable for various heat-intensive applications such as electrical enclosures, automotive parts, and industrial machinery. In summary, aluminum sheets exhibit outstanding fire-resistant properties due to the protective oxide layer, non-combustible nature, and efficient heat dissipation. These properties make them highly desirable for applications where fire safety is essential, providing peace of mind and protecting against potential fire incidents.

- Q: Are the aluminum sheets suitable for manufacturing heat exchanger tubes?

- Yes, aluminum sheets are suitable for manufacturing heat exchanger tubes. Aluminum has excellent thermal conductivity, corrosion resistance, and is lightweight, making it an ideal material for heat transfer applications.

- Q: Can aluminum sheets be roll-formed?

- Yes, aluminum sheets can be roll-formed.

- Q: Can aluminum sheet be used in marine environments?

- Yes, aluminum sheet can be used in marine environments. Aluminum is a popular material choice for marine applications due to its excellent corrosion resistance. It forms a protective oxide layer on its surface, which helps to prevent further corrosion even in saltwater environments. Additionally, aluminum is lightweight, which makes it an ideal choice for marine applications where weight reduction is crucial. Aluminum sheet is commonly used in boat hulls, decks, and other marine structures due to its durability, strength, and resistance to corrosion.

- Q: Can aluminum sheets be used for heat exchanger fins?

- Absolutely, heat exchanger fins can indeed make use of aluminum sheets. Aluminum stands out as a favored option for heat exchanger fins owing to its remarkable thermal conductivity, lightweight attributes, and resistance to corrosion. The utilization of aluminum fins enables efficient heat transfer to take place between the fluid and its surroundings. Moreover, aluminum sheets can be effortlessly molded into diverse fin shapes and sizes, allowing for a great deal of design flexibility. All in all, aluminum sheets prove to be a fitting and frequently employed material for heat exchanger fins.

- Q: What is aluminum sheet?

- Aluminum sheet refers to a thin, flat piece of aluminum that is commonly used in various industries for its lightweight, durable, and corrosion-resistant properties. It can be easily bent, cut, and formed into different shapes, making it versatile for applications such as construction, automotive, aerospace, and packaging.

Send your message to us

Aluminum Sheets for Sale Brisbane - Competitive Price Aluminum Sheet for Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords