Aluminum Pipes Wooden Surface Coating Aluminum Coils for Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Wooden Surface Coating Aluminium Coils for Ceiling Tiles

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Wooden Surface Coating Aluminium Coils for Ceiling Tiles

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Surface Coating Aluminium Coils for Ceiling Tiles

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

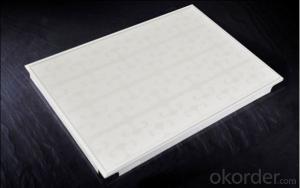

5. Image of Wooden Surface Coating Aluminium Coils for Ceiling Tiles

6. Package and shipping of Wooden Surface Coating Aluminium Coils for Ceiling Tiles

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum pipes be used for structural supports in buildings?

- Yes, aluminum pipes can be used for structural supports in buildings. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for structural applications. It has a high strength-to-weight ratio, allowing it to withstand heavy loads while remaining relatively light. Additionally, aluminum pipes can be easily shaped and welded, making them versatile for various structural designs. However, it is important to consider the specific requirements and regulations of each building project before using aluminum pipes as structural supports.

- Q: Do I need special work permit for cutting aluminum tubes?

- A special job job scope: 1, electrical operation 2, metal welding cutting operation 3, lifting machinery (including elevator), operating 4 motor vehicles in 5, driving high erection and high-altitude hanging industry 6, refrigeration task 7, boiler operation (including water quality test) 8, pressure vessel operation 9, blasting operations 10, mine operations (including gas inspection) 11.

- Q: Shenzhen Jin Rongfa metal materials Co., Ltd., specializing in processing aluminum tubes, aluminum bars, aluminum plate, aluminum processing, oxidation, a variety of anodic oxidation. Sand blast oxidation. Hard anodized, colors, black, blue, red, tyrant gold, rose goldLathe kits and laser marking processing are also provided!

- 5, easy to operate: you can freely design graphics through the computer, easy to operate, power controlled by software. Laser marking machine mainly includes semiconductor laser marking machine, CO2 laser marking machine, optical fiber laser marking machine, YAG vibrating mirror laser marking machine, deep UV laser marking machine and green laser marking machine. Semiconductor laser marking machine features: the use of the light source is a semiconductor laser array, so the optical conversion efficiency is very high, reaching more than 40%; the heat loss is low, without being equipped with cooling system; low power consumption, about 1800W/H. The whole machine performance is very stable, belongs to maintenance free products, the whole machine maintenance free time can reach 15000 hours, equivalent to 10 years maintenance free, no krypton lamp replacement, no supplies. Semiconductor laser marking machine applicable scope: can engrave metal and many kinds of non-metal materials. The utility model is more suitable for occasions needing more precise and higher precision. Used in electronic components, integrated circuit (IC), electrical appliances, mobile phone communications, hardware, tool accessories, precision instruments, watches, jewelry accessories, auto parts, plastic buttons, building materials, PVC pipe, medical equipment and other industries. Applicable materials include: ordinary metals and alloys (iron, copper, aluminum, magnesium, zinc and other metal), rare metals and alloys (gold, silver, titanium), metal oxide (metal oxide can), special surface treatment (phosphate, aluminum anodizing, electroplating, surface material (ABS) shell appliances, commodity), ink (keypad, printing), epoxy resin (electronic components packaging, insulation layer), and computer with arbitrarily change the marking graphics and standard.

- Q: Is it better to choose a radiator, a copper tube or a steel tube?

- The radiator on the computer is copper, should be copper better?

- Q: What is the maximum temperature that aluminum pipes can withstand?

- The maximum temperature that aluminum pipes can withstand depends on several factors, including the specific alloy of aluminum used and the intended application of the pipes. Generally, aluminum pipes can withstand temperatures up to around 400-600 degrees Fahrenheit (200-315 degrees Celsius) without significant deformation or failure. However, it is important to note that prolonged exposure to high temperatures can weaken the material and potentially lead to failure. Therefore, it is crucial to consult the manufacturer's specifications and guidelines to determine the exact maximum temperature limit for a particular aluminum pipe.

- Q: What's the difference between the 6063 aluminum pipe and the 6061 aluminum tube, and it needs to be described in detail,

- The major alloy elements in Alloy 6063 are magnesium and silicon, which have excellent workability, good weldability, extrusion and electroplating, and good resistanceCorrosion resistance, toughness, easy polishing and color film, excellent anodizing effect.

- Q: Can aluminum pipes be used for irrigation controllers?

- Yes, aluminum pipes can be used for irrigation controllers. Aluminum pipes are commonly used in irrigation systems due to their durability, lightweight nature, and resistance to corrosion. They can withstand the harsh outdoor elements and are less likely to break or leak compared to other pipe materials. Additionally, aluminum pipes can be easily manipulated and installed, making them a popular choice for irrigation controllers.

- Q: How to weld the refrigerator aluminum tube?

- Flame welding of aluminium tube for refrigerator1, if the operation of basic skills more solid, with 4047 of aluminum silicon welding wire with 201 of welding powder welding, this melting point is high, suitable for master use2, if it is a surname novice, with copper and aluminum wire using low melting point welding, welding can refer to special "video - how ALCU-Q303 welding of copper aluminum pipe joint"

- Q: Steel pipe can flange connection, aluminum pipe can flange connection? How about copper tubes?

- Both flanges can be connected. The flange is the joint of the pipe and the pipe.Different media, the choice of flange material is different.You say plastic pipes can also come through flanges. Flanges are usually made of nonmetallic material.Teflon can also be done. The wear resistance of PTFE is chenchen.

- Q: Air conditioning copper aluminum tube life is generally a few years?

- The life of the air conditioner is 8-10 years, and no one has ever mentioned the life of the copper tube. Try not to use the aluminum tube.

Send your message to us

Aluminum Pipes Wooden Surface Coating Aluminum Coils for Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords