Aluminum Pipes Wooden Coating Aluminium Coils for Rolling Shutter Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Wooden Coating Aluminium Coils for Rolling Shutter Doors

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Wooden Coating Aluminium Coils for Rolling Shutter Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Coating Aluminium Coils for Rolling Shutter Doors

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

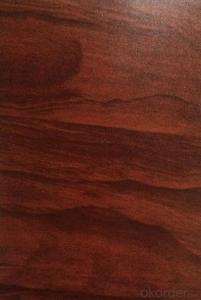

5. Image of Wooden Coating Aluminium Coils for Rolling Shutter Doors

6. Package and shipping of Wooden Coating Aluminium Coils for Rolling Shutter Doors

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: There's a small hole in the aluminum tube on the air conditioner. Can I use it?

- Now the general air conditioner uses the copper tube to walk the refrigerant, you say the aluminum pipe does not know what position. If is refrigerant tube, a hole is impossible to run, the refrigerant had leaked out.If you want to continue to use air conditioning, must find a professional maintenance staff to pipe trap, re filling refrigerant can.

- Q: Are aluminum pipes suitable for oil refineries?

- Depending on the specific requirements and conditions of the refinery, aluminum pipes can be a viable option for use in oil refineries. They offer several advantages that make them suitable for certain applications within the facility. To begin with, the lightweight nature of aluminum pipes makes them easy to transport, install, and handle in a refinery. This characteristic can lead to cost and time savings during the installation and maintenance of the piping system. Furthermore, aluminum has a high resistance to corrosion, especially when exposed to air. This is particularly important in oil refineries where pipes come into contact with corrosive substances like crude oil, petroleum products, and chemicals. The corrosion resistance helps prolong the lifespan of the pipes and reduces the need for frequent replacements or repairs. In addition, aluminum pipes have excellent thermal conductivity. This property allows for efficient heat transfer in refinery processes such as distillation, catalytic cracking, and oil separation. The high thermal conductivity of aluminum pipes can enhance energy efficiency and result in cost savings. However, it is worth noting that aluminum pipes may not be suitable for all applications in oil refineries. For example, they may not be ideal for transporting highly pressurized fluids or in situations involving high temperatures, as aluminum has lower strength and melting point compared to metals like steel. In such cases, it may be more appropriate to use steel or other alloys. In conclusion, the suitability of aluminum pipes in oil refineries depends on the specific requirements, conditions, and limitations of the refinery processes. It is crucial to assess the compatibility of aluminum pipes with the operational needs of the refinery, considering factors such as pressure, temperature, and the nature of the fluids being transported.

- Q: What are the advantages of using aluminum pipes over other materials?

- Using aluminum pipes instead of other materials offers several advantages. Firstly, aluminum pipes are lightweight, making them easy to handle and transport compared to heavier materials like steel or copper. This makes them a popular choice in industries where reducing weight is important, such as aerospace and automotive. Secondly, aluminum pipes have excellent corrosion resistance. They naturally form a protective oxide layer that prevents rust and corrosion, making them suitable for use in moist, chemical, or extreme weather conditions. Additionally, their resistance to corrosion means they last longer and require less maintenance. Furthermore, aluminum pipes have high thermal conductivity, meaning they efficiently transfer heat. This makes them ideal for applications that require heat exchange or thermal management, such as HVAC, refrigeration, and automotive cooling systems. Another advantage of aluminum pipes is their versatility. They can be easily formed into different shapes and sizes due to their malleability. This makes them suitable for a wide range of applications, from plumbing and irrigation systems to structural frameworks and electrical conduits. Lastly, aluminum pipes are environmentally friendly. They are highly recyclable, and the recycling process requires much less energy compared to their initial production. By using aluminum pipes, companies can contribute to sustainability efforts by reducing their carbon footprint and waste. In summary, the benefits of using aluminum pipes include their lightweight nature, excellent corrosion resistance, high thermal conductivity, versatility, and environmental friendliness. These qualities make aluminum pipes a preferred choice in various industries, providing efficiency, durability, and sustainability.

- Q: Are aluminum pipes suitable for potable water tanks?

- Yes, aluminum pipes are suitable for potable water tanks. Aluminum is a lightweight and corrosion-resistant material, making it an excellent choice for water tanks that are used for storing drinking water. Aluminum pipes are also known for their durability and long lifespan, which ensures that the water tank remains in good condition for an extended period. Additionally, aluminum is non-toxic and does not leach harmful substances into the water, making it safe for potable water storage. However, it is essential to ensure that the aluminum pipes are properly coated or lined to prevent any potential reactions between the metal and water, which could affect the water quality.

- Q: What are the different pressure testing methods for aluminum pipes?

- To ensure the integrity and reliability of aluminum pipes, there are multiple methods available for pressure testing. These methods can vary depending on factors like the pipe's application, size, material thickness, and industry standards. It is essential to consult experts or refer to industry codes and regulations to determine the most suitable testing method for a specific situation. One commonly used technique is hydrostatic testing. This method involves filling the aluminum pipe with water or another liquid and pressurizing it to a predetermined level. The pipe is then inspected for leaks or any abnormal behavior under pressure. Hydrostatic testing is a straightforward, cost-effective method that yields accurate results. Alternatively, pneumatic testing can be employed. Instead of using liquid, air or inert gas is used to pressurize the aluminum pipe. The pipe is sealed, and the pressure is gradually increased until the desired test pressure is reached. Any leaks or deformations are then examined. Pneumatic testing is particularly useful when water or other liquids could be harmful to the pipe material. Ultrasonic testing is a non-destructive method that utilizes ultrasonic waves to detect flaws or defects in the aluminum pipe. Transducers are employed to transmit and receive these waves, and changes in their characteristics indicate the presence of defects. This type of testing can be conducted without applying pressure to the pipe. Magnetic particle testing, on the other hand, is specifically designed to identify surface cracks or defects in aluminum pipes. By creating a magnetic field around the pipe and applying finely divided magnetic particles to the surface, any surface defects will attract the particles, making them visible for inspection. Radiographic testing involves using X-rays or gamma rays to examine the internal structure of aluminum pipes. The pipe is exposed to these rays, and the resulting image is analyzed for any defects or abnormalities. While radiographic testing is highly accurate, it requires specialized equipment and trained personnel. In summary, there are several pressure testing methods available for aluminum pipes, including hydrostatic testing, pneumatic testing, ultrasonic testing, magnetic particle testing, and radiographic testing. The selection of the appropriate method depends on various factors, and seeking guidance from experts or referring to industry codes and regulations is crucial for determining the most suitable testing method for a specific situation.

- Q: What is the cost of aluminum pipes compared to other materials?

- The price of aluminum pipes can differ based on various factors like pipe size, thickness, and grade, as well as the current market situation. However, in general, aluminum pipes are usually more cost-effective when compared to materials such as stainless steel or copper. Aluminum, being a lightweight and abundant material, has lower production costs. It is easily accessible, which further contributes to its affordability. Moreover, manufacturing aluminum pipes requires fewer resources and energy compared to other metals, further driving down their cost. On the contrary, materials like stainless steel or copper are typically pricier due to their higher production costs and limited availability. The manufacturing of stainless steel pipes necessitates additional alloying elements and complex processes, thereby increasing their price. Copper pipes, highly regarded for their excellent heat conductivity, are also more expensive due to the higher cost of copper as a raw material. It is important to acknowledge that the precise cost comparison between aluminum pipes and other materials can vary depending on market conditions and specific project requirements. Therefore, it is advisable to consult suppliers or conduct thorough research to obtain accurate pricing information for the desired materials.

- Q: How do you usually process hollow aluminum tubes? I want to make aluminum tubes myself

- An ordinary lathe can be used if continuous casting can be used in large quantities

- Q: we have been cutting copper tube, now cutting aluminum tube, existing cutting machine cutting aluminum pipe burr is too big

- Aluminum tubes have professional aluminum cutting pieces, and the speed is also related

- Q: Can aluminum pipes be used for swimming pool systems?

- Absolutely, swimming pool systems can indeed utilize aluminum pipes. Aluminum, being a lightweight and highly resistant material against corrosion, proves to be an ideal selection for pool systems. It is extensively employed in the piping systems of both residential and commercial swimming pools. The durability and longevity of aluminum pipes are widely recognized, given their ability to withstand even the harshest weather conditions and exposure to chemicals. Moreover, aluminum pipes exhibit exceptional heat conductivity, guaranteeing an efficient transfer of heat for pool heating or cooling systems. All in all, aluminum pipes present themselves as a dependable and economically viable choice for swimming pool systems.

- Q: I used my aluminum tube to make a "Feng" type outdoor antenna, and all the aluminum tubes were connected together. I now have a small piece of aluminum plate, the aluminum plate should be installed in the "Feng" rack in what position, is connected together or insulated from each other?. If all of them are finished, how can the coaxial cable be connected, and the middle axle connected to the "Feng" rack or the aluminum plate?If I can't do this project, then what kind of outdoor antenna should I make for these materials (aluminium tube and aluminum plate)?Thank you all! StopThere is no shop in the place where I am now. Please don't tell me to buy one.

- Homemade antenna is very troublesome, and the effect is not good, it is better to buy a ready-made, not expensive, if you are not afraid of trouble, I can tell you specific methods.

Send your message to us

Aluminum Pipes Wooden Coating Aluminium Coils for Rolling Shutter Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords