Aluminum Pipes Wooden Coating Aluminum Coils for Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Wooden Coating Aluminium Coils for Ceiling Tiles

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Wooden Coating Aluminium Coils for Ceiling Tiles

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Coating Aluminium Coils for Ceiling Tiles

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

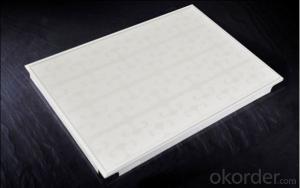

5. Image of Wooden Coating Aluminium Coils for Ceiling Tiles

6. Package and shipping of Wooden Coating Aluminium Coils for Ceiling Tiles

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How to repair the surface defects of aluminum pipe

- First。 Be careful not to cut too much as long as the removal of necking and drawing section and the tail part of cracking can be cut to pay attention, don't put the miter, after cutting in aluminum pipe.Second, pay attention to the material in the aluminum tube shelf should first check it, there is no damage to the surface, and then check it cut when there is no creases, cutting when there is no India, Pakistan and India if the number is small or shallow depth to grind it into later in the shelf, if found it is deep creases or Pakistan and India, the tube will not be able to use the shelves, can not be used as pipe, aluminum pipe mill after the repair to repair welding for leveling.

- Q: Do I need special work permit for cutting aluminum tubes?

- A special job job scope: 1, electrical operation 2, metal welding cutting operation 3, lifting machinery (including elevator), operating 4 motor vehicles in 5, driving high erection and high-altitude hanging industry 6, refrigeration task 7, boiler operation (including water quality test) 8, pressure vessel operation 9, blasting operations 10, mine operations (including gas inspection) 11.

- Q: Can aluminum pipes be used for scaffolding?

- Yes, aluminum pipes can be used for scaffolding. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, making it suitable for scaffolding applications. It is resistant to corrosion, easy to handle, and can be assembled quickly, making it a popular choice for scaffolding systems.

- Q: The difference between aluminium pipe and galvanized steel pipe

- The aluminum surface has a layer of oxide film, melting point at more than 2000 degrees, and the melting point of aluminum is only about 400 degrees. Galvanized sheet is a sheet of zinc plated on sheet iron or carbon steel.

- Q: How is the seamless pipe or tube seam identification for enlighten heroes?

- Just look at the mold and see the directions

- Q: Brass or aluminium tube for internal and external air conditioner?

- Later on, the aluminum pipe will do, and if the housing is unstable, the copper pipe will be better.

- Q: Can aluminum pipes be used for swimming pool systems?

- Yes, aluminum pipes can be used for swimming pool systems. Aluminum is a popular choice for pool systems due to its durability, resistance to corrosion, and lightweight nature. It is commonly used for piping, especially in areas with high moisture or corrosive conditions, making it a suitable option for swimming pool systems.

- Q: Do copper tubes and aluminium tubes react chemically together?

- Depends on what conditions, aluminum is more active than copper, under certain conditions can be a chemical reaction

- Q: What is the difference between the 6061-T6 aluminum pipe and the common aluminum pipe?

- Alcoa 6061-T651 has excellent processing properties, corrosion resistance, high toughness and processing after deformation, color film is easy, excellent oxidation effect and excellent characteristics of good.Al-Mg-Si series alloy, medium strength, with good plasticity and excellent corrosion resistance. Especially the tendency of non stress corrosion cracking, which has good weldability, good corrosion resistance and cold workability, is a widely used and promising alloy. It can be anodized, painted, or painted with enamel. It is suitable for building decoration materials. It contains a small amount of Cu, so the strength is higher than 6063, but the sensitivity of quenching is higher than that of 6063. After extrusion, the air can not be quenched, and it needs to be solved again by solid solution treatment and quenching aging so as to obtain higher strength.

- Q: Seamless tubes and welded aluminum performance is what is the difference between

- 2, with tubes generally do structural support, like some do not need too high precision parts, supporting the role of the general used more, but used fluid.

Send your message to us

Aluminum Pipes Wooden Coating Aluminum Coils for Ceiling Tiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords