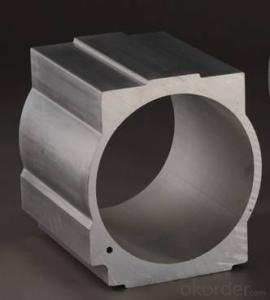

Aluminum Pipes for Vehicle Side Wall Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, Mill,etc |

Colour | -- |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Car body; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: Why is the copper tube of AUX air conditioning aluminum tube?

- Copper tubes are often used as connecting pipes for air conditioners. Air conditioning aluminum tube is also a kind of non-ferrous metal pipe.

- Q: Can aluminum pipes be welded?

- Yes, aluminum pipes can be welded. Aluminum is a highly weldable material and can be easily joined together using various welding processes such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and even oxy-acetylene welding. However, it is important to note that welding aluminum requires specific techniques and considerations due to its unique properties. For instance, aluminum has a higher thermal conductivity and lower melting point compared to other metals, so it requires more heat control during the welding process. Additionally, aluminum forms an oxide layer when exposed to air, which can hinder the welding process. Therefore, proper cleaning and preparation of the aluminum surface is crucial before welding to ensure a strong and sound weld joint.

- Q: Are aluminum pipes suitable for cryogenic applications?

- No, aluminum pipes are not suitable for cryogenic applications.

- Q: Can aluminum pipes be used for swimming pool installations?

- Yes, aluminum pipes can be used for swimming pool installations. Aluminum pipes are known for their durability, resistance to corrosion, and lightweight properties, making them a suitable choice for pool installations. They are commonly used for plumbing and water circulation systems in swimming pools due to their longevity and ability to withstand harsh pool chemicals and outdoor conditions.

- Q: You say that the Internet has said plastic tubes, all sorts of strange things, in line to buy, no seal, the tube body is plastic, but some people say that the Internet is aluminum, hope someone can accurately answer what aluminum tube, which is plastic pipe. Is there a counter here?... High marks seek truthLZ where the city has wooden counters, can not go to the identification.. I've got a map on the Internet. I'm more like the one on the right

- The shea butter creams for 30ml are made of plastic tubes, while shea butter creams for 75ml and 150ml are aluminum tubes

- Q: What are the disadvantages of using aluminum pipes?

- Using aluminum pipes in various applications has several disadvantages. Firstly, their strength and durability are lower compared to materials like steel, making them unsuitable for high-pressure or heavy load applications. The pipes may bend or deform, compromising their functionality. Secondly, aluminum is more prone to corrosion than materials like stainless steel. This is a significant drawback in environments with high humidity, acidic or alkaline conditions, or exposure to certain chemicals. Corrosion can cause leaks or failures in the pipes, potentially damaging the system or infrastructure. Additionally, aluminum pipes have a higher coefficient of thermal expansion than steel. This means they are more likely to expand or contract with temperature changes. This can cause problems in applications requiring precise dimensions or tight fittings, as the pipes may not maintain their original shape or size. Moreover, aluminum pipes are relatively more expensive compared to materials such as PVC or copper. This can be a disadvantage for projects with budget constraints, as the cost of aluminum pipes significantly impacts overall expenses. Lastly, aluminum is a good conductor of heat and electricity. While advantageous in some applications, it can be a disadvantage in others. For instance, in applications involving refrigeration or insulation, aluminum pipes can lead to heat transfer or energy loss, making them less efficient than materials with better insulation properties. In conclusion, the disadvantages of aluminum pipes include lower strength and durability, susceptibility to corrosion, higher coefficient of thermal expansion, higher cost, and potential heat or energy transfer issues. It is crucial to carefully consider these drawbacks in relation to the specific requirements of the application before selecting aluminum pipes as the preferred material.

- Q: Can aluminum pipes be used for hydroponic systems?

- Yes, aluminum pipes can be used for hydroponic systems. Aluminum pipes are lightweight, durable, and resistant to corrosion, making them an ideal choice for hydroponic applications. They can be easily cut and assembled to create a customized hydroponic system that meets the specific needs of plants. Aluminum pipes also have good thermal conductivity, allowing for efficient heat transfer in the system. However, it is important to note that aluminum pipes should be properly coated or lined to prevent any potential leaching of aluminum into the nutrient solution, which can be harmful to plants.

- Q: Can aluminum pipes be used for structural purposes?

- Yes, aluminum pipes can be used for structural purposes. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various structural applications such as building frames, scaffolding, and support structures. Additionally, aluminum pipes offer good strength-to-weight ratio and are easy to work with, making them a popular choice in construction and engineering projects.

- Q: Can aluminum pipes be used for building facades?

- Building facades can indeed utilize aluminum pipes. This material, known for its versatility and durability, is frequently employed in construction due to its lightweight composition, resistance to corrosion, and effortless installation. Aluminum pipes can be tailored to fit a range of sizes and shapes, making them ideal for various architectural designs. Moreover, aluminum can receive various coatings or finishes to enhance its aesthetic appeal and safeguard it from environmental elements. All in all, aluminum pipes are a favored option for building facades, as they provide a harmonious blend of functionality, durability, and design adaptability.

- Q: Which is better, titanium alloy or high pressure aluminium tube?

- In addition, other aspects are titanium alloy victory over aluminum alloy, so to answer this question,

Send your message to us

Aluminum Pipes for Vehicle Side Wall Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords