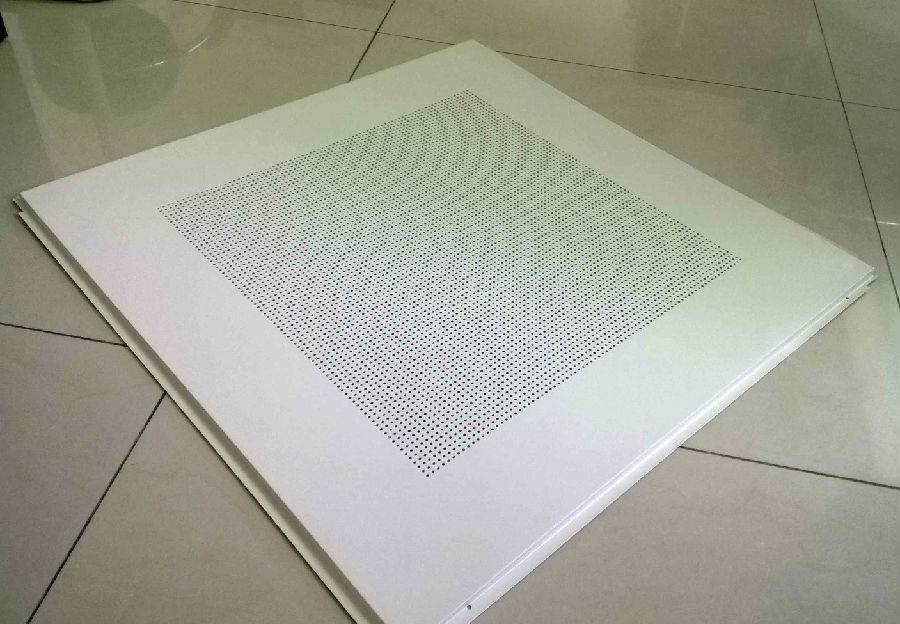

Aluminium Wood Ceiling - Aluminum Metal Decoration Panel Perforated Ceiling

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

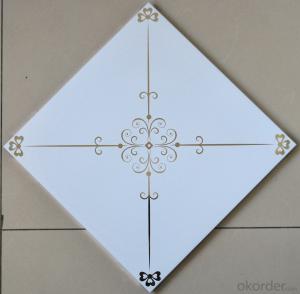

Aluminum Metal decoration panel perforated ceiling

1.Brief introduction

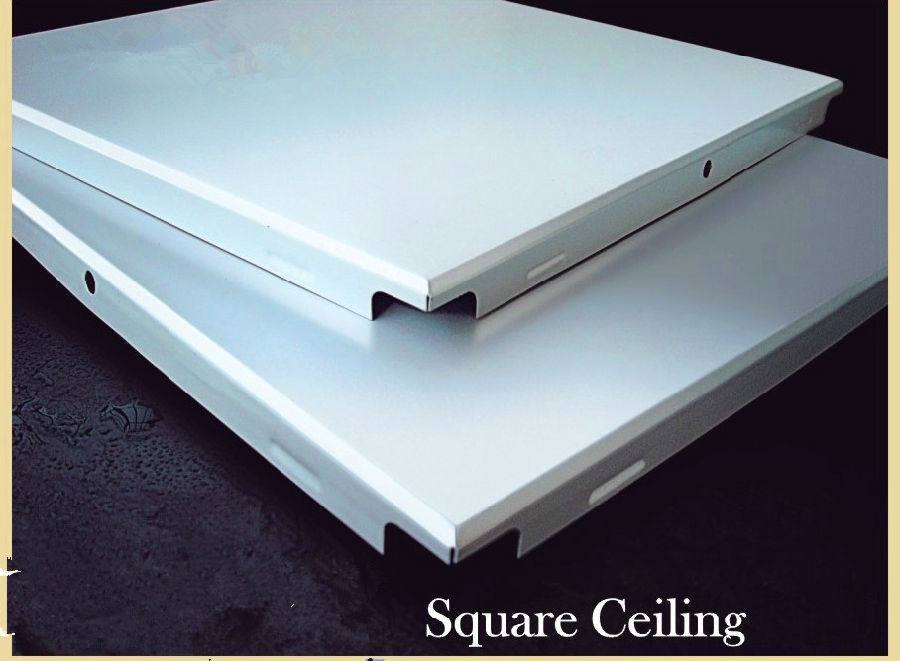

Square ceiling series can be clarified as visible frame type square ceiling and invisible frame type square ceiling.

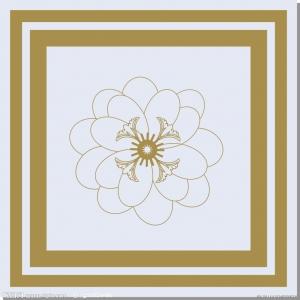

Through special chromising on the surface ,the square ceiling can be colored by spraying powder or polyester coating,so that it can meet different decoration requirements.

2.Base materials

Aluminum alloy ,the grade of aluminum alloy can be selected according to the actual requirements.

Surface veneer:Power coating (ordinary powder ,polyester),rolling ,laminating,metal anode oxidation treatment.

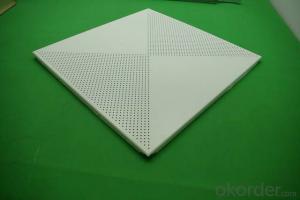

Can be pore panel or punching panel according to the actual requirments.

3.Square ceilings series

1). Plain square ceilings

2). Lay type square ceilings

3). Perforated ceilings

Aluminum Metal decoration panel perforated ceiling

4.Size

Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

585*585(605*605) | 10 | 0.60~0.70 | Square Edge |

5. Application

Perforated false ceiling can be widely applied for office,shopping malls,conference rooms,laboratories and exhibition hall,ect

6.Package

Interior: plastic bags Exterior:in carton

Aluminum Metal decoration panel perforated ceiling

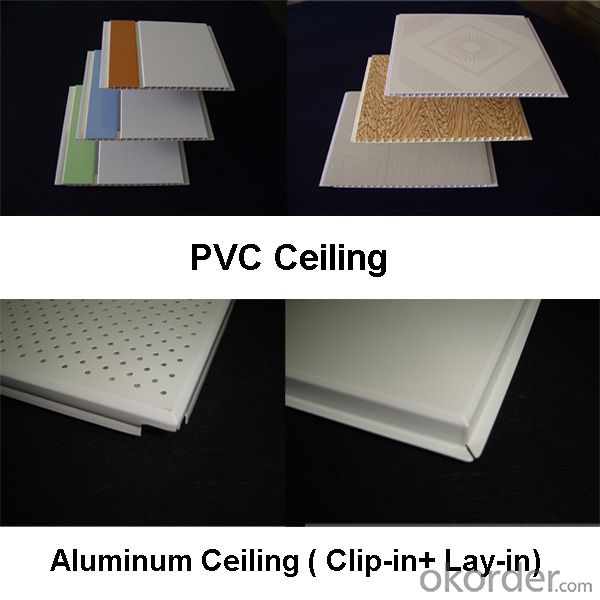

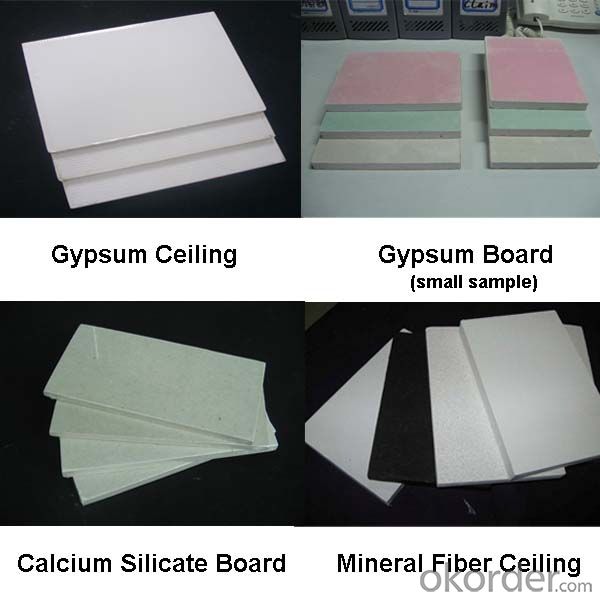

Other products we supply:

- Q: Can the aluminum plate be made of walls? How to build is better, how to install the ground

- I have not heard of doing the wall, the aluminum button board to do the TV backdrop I have seen, in fact, it is relatively simple to do, the idea of fixed triangular keel, with the edge of the edge of the income is normal.

- Q: How to make the kitchen ceiling

- Aluminum buckle board paint, is possible. The key is to see what the paint, the knowledge is very deep, the average buyer is difficult to distinguish. Chinese people's high imitation ability is the strongest. The key lies in the quality of the paint equipment and its own paint

- Q: Kitchen bathroom aluminum plate to the top of the original distance is generally how much?

- If you want to follow the ventilator, Yuba, then, at least stay inside 15 high. Generally in accordance with the height of 2.2 meters -2.4 meters

- Q: What are the properties of aluminum?

- Aluminum heaters are often used to melt refractory metals and welded rails. Aluminum is also used as a deoxidizer in the process of steelmaking. Aluminum powder and graphite, titanium oxide (or other high melting point metal oxide) according to a certain ratio of uniform mixing, coated on the metal, the high temperature calcination and made of high temperature resistant cermet, it has important applications in rocket and missile technology The

- Q: Can you install a lift hanger after lifting the ceiling?

- As long as the above can be strengthened on the line, need a long screw, through the aluminum plate fixed on the wall.

- Q: Are there any insulation for aluminum buckle

- Aluminum plate is a metal plate, the material is relatively thin, good thermal conductivity, difficult to heat. Only relatively thick non-metallic materials to have insulation effects, such as: polymer composite gusset plate, gypsum board and so on.

- Q: 0.8m thick micro-hole Xinglong brand aluminum plate 600 * 600 is what price price

- Normally, the price of 0.6mm thick aluminum plate is 38 yuan / square meter, but some manufacturers will not give you enough 0.6 thick, so that the price is a deviation, foot 0.6mm 600 * 600 aluminum plate The weight should be 1.2 kg.

- Q: Gypsum board smallpox is what things? Easy to use? With aluminum ceiling than how? Which is good.

- Home furnishings gypsum board, kitchen / Wei can use gypsum board, aluminum-plastic plate, aluminum plate, buckle board, sound-absorbing panels, grille; tooling with gypsum board or sound-absorbing panels or grille ceiling

- Q: How to look good or bad

- Look at the keel: keel is good or bad is a lot of consumers ignore the problem, the keel material is generally divided into aluminum, iron and no fingerprint steel. Aluminum keel will not rust, but because the cost is relatively high sales so very little. Iron keel is easy to rust, although the keel section hidden in the back of the ceiling generally do not see, but the rust scattered on the ceiling on the ceiling is not good, over time will affect the stability of the ceiling. No fingerprint steel keel relative to the iron keel it is not so easy to rust, is currently the most commonly used home improvement tooling sales. I sincerely hope that consumers can buy their own ideal integrated ceiling products.

- Q: The top of the kitchen did not line, like the largest reduction in space, at least how high Is the kitchen

- Then the general situation of such a ceiling distance of 800-1200cm Second, the kitchen, home kitchen, then the ceiling is generally between 300-500cm. Recommended at least not less than 20cm.

Send your message to us

Aluminium Wood Ceiling - Aluminum Metal Decoration Panel Perforated Ceiling

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords