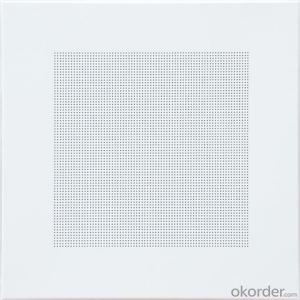

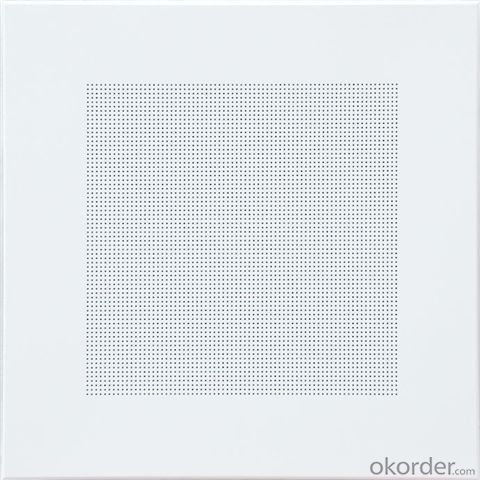

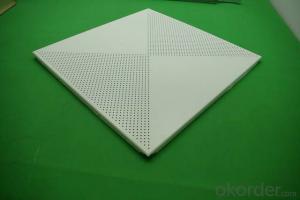

Aluminium Acoustic Ceiling with Aluminium Ceiling Hook - Perforated Aluminum Ceiling

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

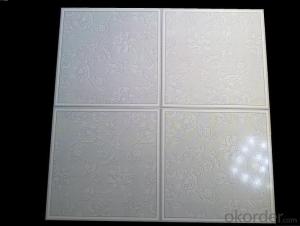

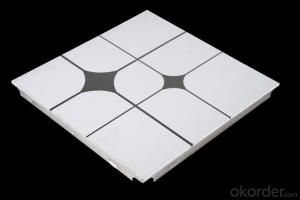

Adopt high-quality aluminum alloy real materials with standard mould, make the ceiling tile install soomth and easy.

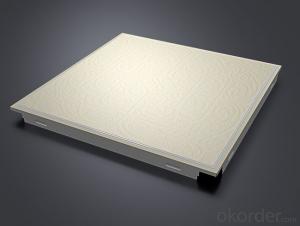

Adopt high quality and ECO-Friendly surface treatment technologies, such as wooden/stone color coated, spray painted, etc., make the ceiling tile beautiful and matching to various spaces.

Product Applications:

♦ Supermarkets, Shopping malls, Shops.

♦ Outdoor facilities, Gas station, Toll station.

♦ Subway Station, Railway Station, Bus station, Airport.

♦ Schools, Offices, Meeting rooms, bookstores. Stadiums.

♦ Building lobby, Corridors, Toilets.

Product Advantages:

1.Durability:

Good materials and sophisticated fabrication technology ensure durability of ceilings throughout their lifespan;

2.Environmental:

Aluminum ceiling does not contain harmful substance to environment. The aluminum alloy is recyclable and reused;

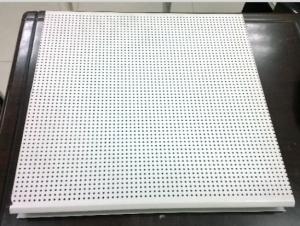

3.Sound absorbing:

Sound absorption function will be increased vastly by perforated holes and non-woven fabric, which is anti-inflammable;

Main Product Features:

(1)Clip-in aluminum ceiling is made from high quality aluminum panels (0.6mm-1.2mm thick).

(2) International standard 1100H24, 3003H24, or 5005H24 aluminum alloy depending on requirements; galvanized iron and stainless steel are made available as well.

(3)Advantages of clip-in aluminum ceiling:

A: light weight, high strength

B: shock resistant, water proof, fire proof, anti-corrosion, anti-fouling

C: simple structure, easy installation and maintenance

D: clear edges and minimized gaps between tiles greatly improve aesthetic effects.

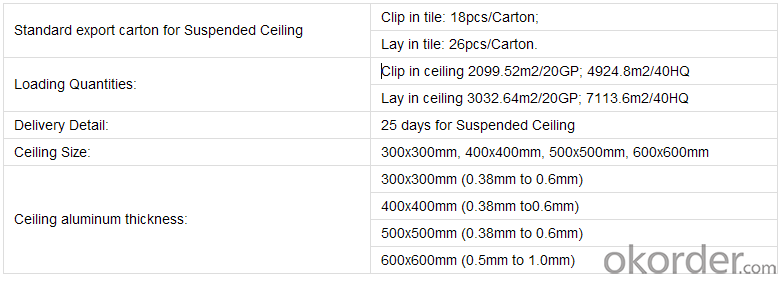

Product Specifications:

FAQ:

Q1: Is your company a manufacturer or a trading company?

A: We are a professional metal building material manufacturer with the advantage of direct and consistant quality control, more competitive pricing and smooth services. We welcome to visit our company and manufacturing site located in Shanghai, China and hope that we can foster a long-term business relationship with you.

Q2: What if I cannot find a desired model in your catalogue or online product displays?

A: With 20 years of experience in landscape projects, we are experienced and expertised to make customized products according to different designing needs. The catalogue only includes part of our standard models. Just tell us what you want to achieve or give us your drawings, and we will find a solution for you.

Q3: What is your accepted payment terms?

A: We prefer T/T,Westunion,and Paypal. We are open to the negotiation about payment terms with our clients before signing up the contract.

Image:

- Q: How to make the kitchen ceiling

- Are basically thermal transfer technology

- Q: How to open the aluminum plate hanging ceiling?

- In the text shop to buy a soft plastic sucker, the first split in the middle, and gradually split the edge of the sucker you will use

- Q: How does the kitchen pick aluminum ceilings?

- Kitchen aluminum buckle ceiling is best to choose flat type. Kitchen smoke and more clean is a big project, you can choose nano-anti-fouling. Kitchen aluminum plate also pay attention to fire resistance and moisture resistance.

- Q: How to install the warm wind Yuba aluminum plate on the ceiling

- Yuba inside the instructions will generally have instructions, Yuba sub-body and the front cover, the body is lying on the integrated ceiling of the keel, the front cover and buckle plate as in the keel.

- Q: Do you want to use the top angle of the ceiling?

- Used to look better.

- Q: Kitchen aluminum plate inlaid with lights, lights do not change how to install how the equipment installed

- Aluminum slab plate of the lamp is the best disassembly! Quite the answer to the first floor - more detailed - hands try to know;

- Q: How to distinguish between the integrated ceiling aluminum plate girders good or bad

- Accessories ?????? Accessories are also a decision price factors, accessories mainly refers to the keel, and now most of the home decoration is not easy to deformation, with fire performance of light steel keel, the selection should pay attention to the thickness of the keel, good keel thickness of not less than 0.6 mm. Good keel is hot plate galvanized keel, above the snow-like pattern, strength, corrosion resistance higher. The strength of the manufacturers of the keel has its own trademark, and no-name no.

- Q: Aluminum buckle plate and steel which is better

- With aluminum plate than good The reason is as follows: First, this is currently used in the decoration of the methods and options. Second, aluminum plate price is moderate, no deformation. Third, especially good to do clean, when the oil contamination, just wipe with a detergent cloth wipe on the line.

- Q: What is the difference between aluminum-plastic and aluminum-plated boards?

- Aluminum-plastic plate is 1.2 * 2.4 meters of double-layer decorative materials, mainly used in outdoor facade, but also useful in the interior to do background and shape. Aluminum plate is a piece of aluminum, mainly used in the kitchen and bathroom ceiling.

- Q: Gypsum board smallpox is what things? Easy to use? With aluminum ceiling than how? Which is good.

- Home furnishings gypsum board, kitchen / Wei can use gypsum board, aluminum-plastic plate, aluminum plate, buckle board, sound-absorbing panels, grille; tooling with gypsum board or sound-absorbing panels or grille ceiling

Send your message to us

Aluminium Acoustic Ceiling with Aluminium Ceiling Hook - Perforated Aluminum Ceiling

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords