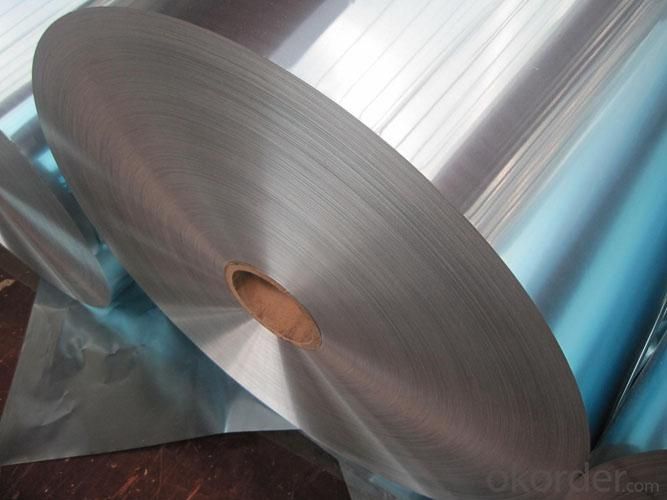

Aluminum Lamination Packaging Foilstock

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details of Aluminum Foilstock For Lamination Packaging Foil

|

Application: |

Cigarette Package, Aseptic Package, Pouches, Sachets |

|

Alloy: |

1235/8011/8079 |

|

Temper: |

O |

|

Thickness & Tolerance: |

0.006mm-0.009mm (±6%) |

|

Width & Tolerance: |

200mm-1650mm (±1mm) |

|

Mechanical Properties: |

Tensile Strength(U.T.S)≥40Mpa, Elongation≥1% |

|

Standard: |

GB/T3198 / ASTM-B209 / EN546 |

Usage/Application of Aluminum Foilstock For Lamination Packaging Foil

Used for flexible packaging, cigarette packages, aseptic packages, pouches, sachets.

Packaging & Delivery of Aluminum Foilstock For Lamination Packaging Foil

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Is it possible to utilize aluminum as a material for manufacturing solar cells?

- <p>Aluminum is not typically used to make solar cells due to its properties. Solar cells are usually made from materials like silicon, which is a semiconductor and can efficiently convert sunlight into electricity. Aluminum, being a good conductor, is used in the manufacturing process of solar cells for its electrical conductivity, but not as the active material that generates electricity. It is used in the form of aluminum paste in the back surface field of solar cells to create a conductive layer and in the frame to provide structural support. However, for the photovoltaic conversion process itself, other materials are more suitable.</p>

- Q: Is it possible to use aluminum as a substance that accelerates chemical reactions?

- <p>Aluminum is not typically used as a catalyst in chemical reactions. Catalysts are substances that increase the rate of a chemical reaction without being consumed in the process. Aluminum, being a metal with a +3 oxidation state, does not readily participate in reactions where it could act as a catalyst. Instead, it is more commonly used in its elemental form for structural purposes or as a reducing agent in certain chemical processes. However, aluminum compounds, such as alumina (Al2O3), can be used as catalysts or catalyst supports in specific industrial applications.</p>

- Q: What is the advantage of the aluminum mine in the Yangtze River than other aluminum products?

- What are the advantages of Mengniu and Yili? Brands are pretty much the same!

- Q: This question asks for an enumeration of different types of aluminum alloys.

- <p>Aluminum alloys are categorized based on their primary alloying elements and their applications. Some common types include: 1) 1000 series (99% pure aluminum), 2) 2000 series (alloyed with copper), 3) 3000 series (alloyed with manganese), 4) 4000 series (alloyed with silicon), 5) 5000 series (alloyed with magnesium), 6) 6000 series (alloyed with magnesium and silicon), and 7) 7000 series (alloyed with zinc). These alloys have various properties, making them suitable for different industries such as aerospace, automotive, and construction.</p>

- Q: Is it possible to recycle old aluminum products and use them to create new aluminum products?

- <p>Yes, old aluminum products can be recycled and reused to make new ones. Recycling aluminum is a highly efficient process that conserves resources and energy. The recycling process involves melting down the old aluminum, which requires significantly less energy compared to extracting aluminum from raw materials. This makes aluminum one of the most recycled materials in the world, with a closed-loop recycling system that allows for continuous reuse without significant loss in quality.</p>

- Q: What are the positive environmental impacts of utilizing recycled aluminum over newly produced aluminum?

- <p>Using recycled aluminum has several environmental benefits. It conserves natural resources by reducing the need for bauxite mining, which is the primary source of aluminum. Recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials, which can lead to a substantial reduction in greenhouse gas emissions. Additionally, recycling aluminum helps in reducing landfill waste, as it diverts used aluminum products from landfills. Moreover, it decreases the environmental impact associated with the production process, such as water pollution and habitat destruction. Overall, recycling aluminum is a more sustainable practice that contributes to a lower carbon footprint and a healthier environment.</p>

- Q: This question asks for an overview of the environmental effects resulting from the production of aluminum.

- <p>Aluminum production has several significant environmental impacts. The process is energy-intensive, contributing to high greenhouse gas emissions, primarily CO2, which exacerbates climate change. It also generates hazardous waste, such as red mud, a byproduct rich in alkaline and heavy metals that can contaminate soil and water if not properly managed. Air pollution is another concern, with emissions of particulates and sulfur dioxide affecting air quality. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction, impacting biodiversity. Water usage in the production process is substantial, which can strain local water resources. Lastly, the release of fluoride compounds can have detrimental effects on human health and the environment.</p>

- Q: This question asks for various applications or purposes that can be served by using aluminum scrap material.

- <p>Aluminum scrap can be repurposed in numerous ways due to its recyclability and durability. Some alternative uses include manufacturing new aluminum products, such as cans, foil, and automotive parts. It can also be used in construction for materials like window frames and roofing. Additionally, aluminum scrap is utilized in the production of everyday items like bicycles, furniture, and even in some types of cookware. Furthermore, it can be employed in the aerospace industry for aircraft parts and in the electronics industry for components. Recycling aluminum scrap not only conserves resources but also reduces energy consumption and environmental impact.</p>

- Q: Is it possible to use aluminum as a material for battery production?

- <p>Yes, aluminum can be used to make batteries. Aluminum-air batteries are a type of metal-air battery where aluminum serves as the anode and undergoes oxidation. These batteries have a high energy density and are environmentally friendly, as they produce minimal waste. However, they face challenges such as water sensitivity and the need for alkaline electrolytes, which limit their practical applications. Research is ongoing to improve their performance and make them more viable for widespread use.</p>

- Q: Is it possible to develop allergies from exposure to aluminum found in food packaging materials?

- <p>While aluminum is commonly used in food packaging materials, the risk of allergic reactions to aluminum is generally low for most people. Aluminum is not a known allergen, and exposure through packaging is typically minimal. However, individuals with a rare condition called contact dermatitis may experience skin irritation from aluminum. For the general population, the risk of allergic reactions due to aluminum in food packaging is negligible. It's always important to monitor any unusual reactions and consult a healthcare professional if concerned.</p>

Send your message to us

Aluminum Lamination Packaging Foilstock

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords