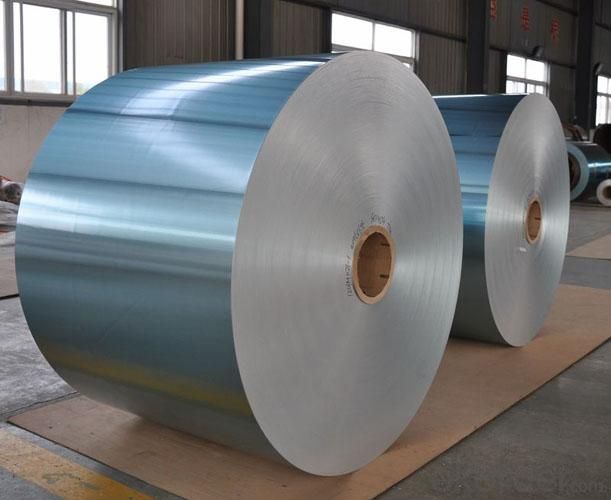

Aluminum Lacquered Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details of Lacquered Aluminum Foil

|

Application: |

PTP foil, cold-forming foil, alu-alu foil,medicine packaging foil |

|

Alloy: |

8011/8006/8079 |

|

Temper: |

H18/O |

|

Thickness& Tolerance: |

0.02mm-0.09mm (±6%) |

|

Width& Tolerance: |

200mm-1650mm (±1mm) |

|

Lacquer: |

HSL for PVC |

|

Primer: |

Primer for printing |

|

Standard: |

GB/T3198 / ASTM-B209 / EN546 |

Usage/Application of Lacquered Aluminum Foil

PTP foil, cold-forming foil, alu-alu foil,medicine packaging foil

Packaging & Delivery of Lacquered Aluminum Foil

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: This question asks about the impact of adding silicon to aluminum alloys on their characteristics.

- <p>Adding silicon to aluminum alloys significantly enhances their properties. Silicon increases the alloy's strength and hardness, making it more durable. It also improves the alloy's resistance to corrosion, particularly in harsh environments. The addition of silicon can also reduce the melting point of the alloy, which can be beneficial for casting processes. However, it should be noted that excessive silicon content can lead to a decrease in ductility and workability of the alloy. Overall, silicon is a common alloying element used to improve the mechanical properties and performance of aluminum alloys in various applications.</p>

- Q: Is it possible to utilize aluminum in the construction of automobiles?

- <p>Yes, aluminum is widely used in automobiles due to its lightweight, high strength, and excellent corrosion resistance. It is commonly found in engine components, body panels, and wheels. The use of aluminum can lead to reduced vehicle weight, which improves fuel efficiency and reduces emissions. Additionally, aluminum's recyclability makes it an environmentally friendly choice for automotive manufacturing.</p>

- Q: Is it feasible to use pure aluminum for the production of coins or medals that maintain their longevity and aesthetics?

- <p>While pure aluminum is lightweight and corrosion-resistant, it is not typically used for making coins or medals due to its low melting point and softness. Coins and medals often require materials that are harder and more durable to withstand wear and tear over time. Additionally, pure aluminum is less visually appealing as it does not have the luster or reflective qualities of other metals like silver or gold. Alloys are generally preferred for coinage and medals because they offer better durability, resistance to wear, and can be tailored to have specific properties like hardness and resistance to corrosion.</p>

- Q: Is it possible to utilize aluminum as a material for automotive construction?

- <p>Yes, aluminum is commonly used in cars. It is valued for its lightweight properties, which can improve fuel efficiency and reduce emissions. Aluminum is used in various parts of a vehicle, including engine components, body panels, and suspension systems. Its high strength-to-weight ratio and resistance to corrosion make it an ideal material for automotive applications.</p>

- Q: This question asks for a list of typical alloys that are used in the manufacturing process of aluminum.

- <p>Common alloys used in aluminum production include 1000 series (99% pure aluminum), 2000 series (aluminum-copper), 3000 series (aluminum-manganese), 4000 series (aluminum-silicon), 5000 series (aluminum-magnesium), 6000 series (aluminum-magnesium-silicone), and 7000 series (aluminum-zinc). These alloys are chosen for their specific properties, such as strength, corrosion resistance, and workability, which make them suitable for various applications like aerospace, automotive, construction, and consumer goods.</p>

- Q: Explain the differences between aluminum and other metals concerning their ability to degrade or break down in the environment.

- <p>Aluminum is not biodegradable in the traditional sense, meaning it does not break down into simpler substances through natural processes. It is highly resistant to corrosion and can persist in the environment for a long time. Unlike metals like iron, which rust and degrade over time, aluminum remains largely intact. However, aluminum can react with other elements in the environment, such as oxygen, to form a thin layer of aluminum oxide on its surface, which can alter its properties. Other metals like magnesium and zinc are more biodegradable as they can corrode and break down more readily in certain conditions, contributing to their use in biodegradable materials.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum foil in the culinary process.

- <p>Aluminum foil offers several advantages in cooking, such as easy clean-up, even heat distribution, and the ability to create a seal for steaming or baking. It's also versatile, being suitable for both roasting and wrapping food for baking. However, there are disadvantages, including potential health concerns due to the leaching of aluminum into food, especially at high temperatures. Additionally, foil can tear easily, and it's not suitable for non-stick surfaces or use under broilers. Environmentally, it's not biodegradable and contributes to waste, which is a significant disadvantage.</p>

- Q: This question asks for the specific temperature at which aluminum changes from a solid to a liquid state.

- <p>The melting point of aluminum is approximately 660.32 degrees Celsius (1220.58 degrees Fahrenheit). This is the temperature at which solid aluminum begins to melt and transform into a liquid state.</p>

- Q: Explain how aluminum influences the synthesis and function of neurotransmitters.

- <p>Aluminum has been suggested to affect the production of neurotransmitters by potentially disrupting the normal functioning of enzymes and receptors involved in neurotransmitter synthesis and release. It may interfere with the uptake of essential metals like magnesium and zinc, which are crucial for the proper functioning of neurotransmitter systems. Aluminum can also alter the permeability of cell membranes, affecting the transport of neurotransmitters across the synaptic cleft. Additionally, there is evidence that aluminum may contribute to oxidative stress, which can impair the synthesis and function of neurotransmitters. However, it's important to note that the exact mechanisms are not fully understood, and more research is needed to establish a definitive link between aluminum exposure and neurotransmitter dysfunction.</p>

- Q: This question asks about the various applications and purposes of aluminum in different industries and everyday life.

- <p>Aluminum is widely used due to its lightweight, corrosion resistance, and high thermal and electrical conductivity. It's extensively used in the transportation industry for manufacturing vehicles, airplanes, and ships. In construction, it's used for window frames, roofing, and structural components. Aluminum is also prevalent in packaging, particularly for food and beverages, and in electrical components like wiring and capacitors. Additionally, it's used in everyday items such as cans, foil, and cookware, and in industrial machinery and tools. Its versatility and recyclability make it a valuable material across many sectors.</p>

Send your message to us

Aluminum Lacquered Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords