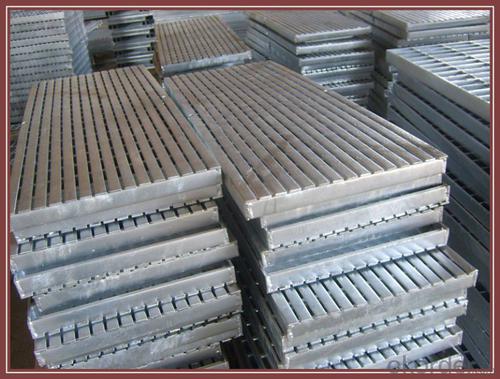

Wholesale Aluminum Foil Sheets for Aluminum Grate Drainage Trench Cover or Manhole Cove

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Do 101 aluminum sheets have any specific certifications or standards?

- Yes, 101 aluminum sheets typically have certifications and standards that ensure their quality and performance. These may include certifications like ASTM (American Society for Testing and Materials) and standards such as AA (Aluminum Association) standards, which verify the material's composition, mechanical properties, and manufacturing processes. Additionally, specific industry certifications like ISO 9001 (International Organization for Standardization) may be applicable to ensure consistent quality control during production.

- Q: How do you prevent warping of aluminum sheets during machining?

- There are several measures that can be taken to prevent warping of aluminum sheets during machining: 1. Proper material selection is crucial in minimizing warping. Opt for aluminum alloys with lower levels of thermal expansion, like 6061 or 7075, as they are less prone to warping. 2. It is recommended to stabilize the material before machining by annealing or stress-relieving the aluminum sheets. This process reduces internal stresses and decreases the likelihood of warping. 3. Ensure the use of appropriate cutting tools. Opt for tools with sharp edges and proper geometry to minimize heat generation and facilitate efficient chip removal. Carbide or diamond-coated tools are often preferred for their high heat resistance when machining aluminum. 4. Minimize heat generation during machining, as excessive heat can cause warping. Implement the use of coolant or lubricants to reduce friction and dissipate heat. Continuous cooling helps maintain a stable temperature and prevents warping. 5. Properly control cutting parameters such as cutting speed, feed rate, and depth of cut to prevent warping. High cutting speeds or excessive material removal rates generate excessive heat, which leads to warping. Experimentation and experience should determine the optimal parameters. 6. Use appropriate fixturing during machining to minimize the chances of warping. Securely clamp the aluminum sheets using suitable fixtures or jigs to maintain stability and prevent movement. 7. Consider employing machining techniques like climb milling or ramping, which reduce vibrations and ensure a smoother cutting process, thereby reducing the risk of warping. 8. After machining, it is advisable to stress-relieve the aluminum sheets again. This step further reduces any residual stress that may have developed during the machining process. By adhering to these steps, the chances of warping during the machining of aluminum sheets can be significantly reduced, resulting in high-quality finished products.

- Q: I was watching an old Star Trek movie. The last one with the full original cast; where they bring two whales into the future. There is a scene in which Scotty and Bones are trying to get material to build a giant tank to hold the whales inside the Klingon space ship. They go to a manufacturer and offer him the formula for Clear Aluminum in exchange for the materials. Scotty and Bones don't know who invented Clear Aluminum and the manufacturer who will eventually place the patent in the 20th century didn't really invent it, so who did? If you think of this as a thought experiment would this prove that other universes exist? Did Scotty and Bones create a new universe?

- Nichols was eventually recognized as the inventor of transparent aluminum.

- Q: Can aluminum sheets be used for electrical applications?

- Yes, aluminum sheets can be used for electrical applications. Aluminum is a highly conductive material, with nearly 60% of the electrical conductivity of copper. This makes it suitable for various electrical applications such as wiring, bus bars, transformers, and electrical panels. Aluminum sheets are commonly used in the construction of electrical enclosures and housings due to their lightweight and corrosion-resistant properties. Additionally, aluminum is cost-effective compared to other metals like copper, making it a popular choice in many electrical applications.

- Q: 1100 scope of application of aluminum plate

- 1100 aluminum plate is generally used in utensils, heat sink, caps, printing plates, building materials, heat exchanger components, but also can be used as deep stamping products. It is widely used in various fields ranging from cooking utensils to industrial equipment

- Q: Aluminum knowledge. What is the model 3003 H24? What does H mean?

- 3003 is aluminium manganese alloy aluminum plate (Al--Mn), which is mainly composed of manganese.H24: continuous casting, continuous rolling, Zhang Liqiang and partial toughening.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.Aluminium alloy is added in the process of aluminum alloy elements (main alloying elements copper, silicon, magnesium, zinc, manganese, minor alloying elements such as nickel, iron, chromium, titanium, lithium, etc.) in order to improve the mechanical properties of aluminum and chemical index. Alloy aluminum sheet has some special properties of pure aluminum plate, and is widely used in special environment, such as ship, refrigerator, mould, aerospace equipment, etc..

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Yes, aluminum sheets are suitable for pharmaceutical applications. They are commonly used for packaging pharmaceutical products due to their excellent barrier properties, lightweight nature, and resistance to corrosion. Aluminum sheets help to protect the contents from moisture, oxygen, and light, ensuring the stability and effectiveness of pharmaceutical drugs. Additionally, aluminum sheets can be easily formed into different shapes, making them ideal for creating blister packs, caps, and closures for pharmaceutical packaging.

- Q: What are the fire-resistant properties of aluminum sheets?

- Aluminum sheets have excellent fire-resistant properties due to their high melting point, which is around 660°C (1220°F). They do not burn or release any harmful gases when exposed to fire. Additionally, the oxide layer that forms naturally on the surface of aluminum provides further protection against fire by acting as a barrier that prevents the metal from direct contact with flames.

- Q: What are the effects of aluminum sheet manufacturing on the environment?

- <p>Aluminum sheet manufacturing factories can have significant environmental impacts. The process involves high energy consumption, which contributes to greenhouse gas emissions and climate change. Additionally, the production process can generate various pollutants, including particulate matter and hazardous chemicals, which can contaminate air and water resources. Land degradation can also occur due to mining activities for bauxite, the primary raw material for aluminum. Moreover, improper disposal of aluminum waste can lead to soil and water pollution. However, with advancements in technology and sustainable practices, the industry is making efforts to reduce its environmental footprint.</p>

- Q: This question asks for the common types of aluminum sheet windows and doors that are available in the market.

- <p>Common types of aluminum sheet windows and doors in the market include sliding windows, casement windows, fixed windows, and awning windows. For doors, there are sliding doors, swing doors, folding doors, and automatic doors. Each type has specific features and applications, such as sliding windows being space-saving and easy to operate, while casement windows offer better ventilation. Sliding doors are popular for their smooth operation and minimal space requirement, and swing doors are traditional and widely used for their durability and security. These aluminum products are valued for their strength, durability, and low maintenance requirements.</p>

Send your message to us

Wholesale Aluminum Foil Sheets for Aluminum Grate Drainage Trench Cover or Manhole Cove

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords