Aluminum Grade A1xxx Cold Rolled CC Circle

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

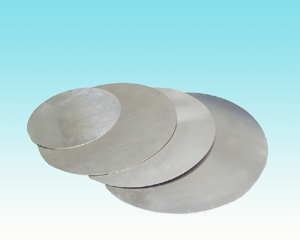

1.Structure of Aluminum Cirlces C.C Quality 1xxx Description:

Aluminum circles C.C quality 1xxx is made from aluminum coils 1xxx. Aluminum circles C.C quality 1xxx has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum circles C.C quality 1xxx are widely used for kitchen wares including fried pans, non-sticky pans, cooking pots,hard anodized cookware, pressure cooker and house hold utensils.

2. Aluminum Cirlces D.C Quality 1xxx Quality Specification:

A1XXX Hot Rolled DC Aluminium Circle

1) alloy number 1050 1060 1070 1100 1200 3003.

2) temper available O H12 H14 H16 H18.

3) application: cookware utensil and basin.

4) thickness: 0.5-4.0mm.(+/-0.02mm)

5) diameter: 100-1200mm.(+/-0.5mm)

6) production treatment: cold rolled

7) surface appearance: flat clean surface no scratch, oil dirty and oxidation.

8) cutting edge: neat cutting edge no burrs.

3.Aluminum Circles D.C Quality 3XXX Images

4. FAQ of D.C Quality 1xxx Specification:

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the quality.

B.When will you deliver the products?

The goods will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What is the advantage of the aluminum mine in the Yangtze River than other aluminum products?

- What are the advantages of Mengniu and Yili? Brands are pretty much the same!

- Q: This question asks about the impact of adding silicon to aluminum alloys on their characteristics.

- <p>Adding silicon to aluminum alloys significantly enhances their properties. Silicon increases the alloy's strength and hardness, making it more durable. It also improves the alloy's resistance to corrosion, particularly in harsh environments. The addition of silicon can also reduce the melting point of the alloy, which can be beneficial for casting processes. However, it should be noted that excessive silicon content can lead to a decrease in ductility and workability of the alloy. Overall, silicon is a common alloying element used to improve the mechanical properties and performance of aluminum alloys in various applications.</p>

- Q: Explain the impact of adding magnesium to aluminum alloys on their characteristics.

- <p>Adding magnesium to aluminum alloys significantly enhances their strength, especially in the form of heat-treatable alloys known as Al-Mg or 5000 series alloys. Magnesium increases the alloy's resistance to corrosion, improves its formability, and raises its mechanical strength. These alloys are often used in applications requiring high strength-to-weight ratios, such as in the aerospace and automotive industries. The addition of magnesium also improves the alloy's weldability and resistance to stress corrosion cracking. However, it's important to note that excessive magnesium can lead to reduced ductility and increased susceptibility to stress corrosion cracking, so the amount added must be carefully controlled.</p>

- Q: This question asks about the chemical reaction between aluminum and elements in the halogen group.

- <p>Aluminum reacts with halogens to form aluminum halides. The reaction is typically exothermic and can be represented by the general equation: 2Al + 3X2 鈫?2AlX3, where X represents a halogen (fluorine, chlorine, bromine, iodine, or astatine). For example, when aluminum reacts with chlorine, it forms aluminum chloride (AlCl3). The reaction is often initiated by heating the aluminum, which is then rapidly oxidized by the halogen. This process is used industrially to produce aluminum halides, which are important in various chemical applications.</p>

- Q: This question asks about the energy consumption involved in the recycling process of aluminum.

- <p>Recycling aluminum requires significantly less energy compared to producing aluminum from raw materials. It takes about 5% of the energy needed to produce new aluminum from bauxite ore. This energy efficiency is due to the fact that recycling aluminum involves melting down the metal, which requires less energy than the extraction and refining processes involved in primary production. The exact amount of energy saved can vary depending on factors such as the purity of the recycled material and the efficiency of the recycling process, but overall, recycling aluminum is a much more energy-efficient method than mining and refining new aluminum.</p>

- Q: This question asks about the relationship between the purity of aluminum and its properties, as well as how purity influences its applications.

- <p>The purity of aluminum significantly affects its properties and uses. High-purity aluminum is soft, ductile, and has excellent electrical and thermal conductivity, making it ideal for applications like electrical wiring and heat sinks. However, its low strength limits its structural applications. To enhance its strength, aluminum is often alloyed with elements like copper, magnesium, and silicon, which increase its hardness and strength while maintaining lightness. These alloys are used in various industries, including aerospace, automotive, and construction. The purity also influences corrosion resistance; high-purity aluminum is more resistant to corrosion than its alloyed counterparts. Therefore, the choice of aluminum's purity and alloying depends on the specific requirements of the intended application.</p>

- Q: This question asks for a brief explanation of the process of recycling aluminum.

- <p>Aluminum recycling involves several steps. First, aluminum waste is collected and sorted. It is then cleaned to remove any contaminants. The cleaned aluminum is melted in a furnace at high temperatures, which is an energy-efficient process as aluminum has a lower melting point compared to other metals. The molten aluminum is then poured into molds to form new products. This process is highly sustainable as it saves energy and reduces waste, with recycled aluminum requiring only 5% of the energy needed to produce new aluminum from raw materials. Recycled aluminum maintains its quality, making it an ideal material for continuous recycling.</p>

- Q: Explain the differences between aluminum and other metals concerning their ability to degrade or break down in the environment.

- <p>Aluminum is not biodegradable in the traditional sense, meaning it does not break down into simpler substances through natural processes. It is highly resistant to corrosion and can persist in the environment for a long time. Unlike metals like iron, which rust and degrade over time, aluminum remains largely intact. However, aluminum can react with other elements in the environment, such as oxygen, to form a thin layer of aluminum oxide on its surface, which can alter its properties. Other metals like magnesium and zinc are more biodegradable as they can corrode and break down more readily in certain conditions, contributing to their use in biodegradable materials.</p>

- Q: What are the negative aspects or drawbacks of using aluminum?

- <p>Aluminum has several disadvantages. It is a non-magnetic material, which limits its use in applications requiring magnetic properties. Aluminum is also less dense than many other metals, making it less suitable for heavy-duty applications. It can be toxic in certain forms, such as aluminum salts, and has been linked to health issues when ingested in large amounts. Additionally, aluminum's low melting point can be a disadvantage in high-temperature environments. Lastly, the production process of aluminum is energy-intensive and can contribute to environmental pollution.</p>

- Q: Is aluminum a suitable material for use in electronic components or devices?

- <p>Yes, aluminum is used in electronics, primarily for its excellent thermal conductivity and electrical conductivity. It is commonly used in heat sinks to dissipate heat from electronic components, such as CPUs and power transistors. Additionally, aluminum is utilized in capacitors and as a conductor in wiring due to its low electrical resistance. However, it is not used as widely as copper for electrical conductivity applications due to copper's superior properties.</p>

Send your message to us

Aluminum Grade A1xxx Cold Rolled CC Circle

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches