Aluminum A1xxx Cold Rolled Circle Alloy CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

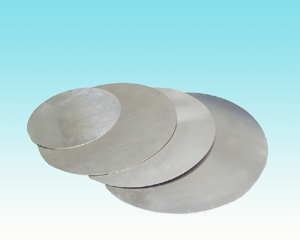

1.Structure of Aluminum Cirlces C.C Quality 1xxx Description:

Aluminum circles C.C quality 1xxx is made from aluminum coils 1xxx. Aluminum circles C.C quality 1xxx has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum circles C.C quality 1xxx are widely used for kitchen wares including fried pans, non-sticky pans, cooking pots,hard anodized cookware, pressure cooker and house hold utensils.

2. Aluminum Cirlces D.C Quality 1xxx Quality Specification:

A1XXX Hot Rolled DC Aluminium Circle

1) alloy number 1050 1060 1070 1100 1200 3003.

2) temper available O H12 H14 H16 H18.

3) application: cookware utensil and basin.

4) thickness: 0.5-4.0mm.(+/-0.02mm)

5) diameter: 100-1200mm.(+/-0.5mm)

6) production treatment: cold rolled

7) surface appearance: flat clean surface no scratch, oil dirty and oxidation.

8) cutting edge: neat cutting edge no burrs.

3.Aluminum Circles D.C Quality 3XXX Images

4. FAQ of D.C Quality 1xxx Specification:

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the quality.

B.When will you deliver the products?

The goods will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: This question asks for a list of typical metal alloys that are utilized in the production of cars.

- <p>Common alloys used in automobile manufacturing include steel alloys such as low carbon steel, high-strength steel, and stainless steel for body and frame construction. Aluminum alloys are also widely used for their lightweight properties, especially in engine components and body panels. Magnesium alloys are employed for parts requiring high strength-to-weight ratios. Additionally, cast iron is used for engine blocks and cylinder heads, while copper alloys are utilized in radiators and electrical wiring. Titanium alloys find use in high-performance or luxury vehicles for their exceptional strength and low weight.</p>

- Q: What are the distinctions between aluminum foil and aluminum sheet in terms of thickness, usage, and properties?

- <p>Aluminum foil and aluminum sheet are both made from aluminum but differ in thickness and usage. Aluminum foil is very thin, typically ranging from 0.0005 to 0.1 inches, and is used for food packaging, cooking, and insulation. It is lightweight, flexible, and has excellent barrier properties against light, air, and moisture. Aluminum sheet, on the other hand, is thicker, usually from 0.2 to 2 inches, and is used in construction, automotive, and aerospace industries due to its strength and durability. It is less flexible than foil but offers greater rigidity and can withstand higher temperatures and pressures.</p>

- Q: What other applications can aluminum be utilized for in the manufacturing industry besides common uses?

- <p>Aluminum has a wide range of alternative uses in manufacturing due to its lightweight, corrosion resistance, and strength. It is used in the automotive industry for car parts to reduce weight and improve fuel efficiency. In aerospace, aluminum is crucial for aircraft construction due to its strength-to-weight ratio. It's also used in the construction of buildings for window frames, roofing, and facades. In the packaging industry, aluminum is used for food and beverage cans, as well as pharmaceutical blister packs. Additionally, aluminum is utilized in electrical components like wiring and transformers due to its excellent conductivity. It's also found in various consumer goods, such as bicycles, sports equipment, and electronic devices.</p>

- Q: Explain how aluminum influences the propagation of sound waves.

- <p>Aluminum has a high density and stiffness, which makes it an effective conductor of sound. When sound waves hit an aluminum surface, the vibrations are quickly transmitted through the material due to its low internal damping. This results in a clear and efficient transfer of sound energy. However, aluminum's high reflectivity can also lead to a significant amount of sound being reflected rather than absorbed, which can affect the acoustics in a space, potentially causing echoes or reducing sound absorption. Additionally, aluminum's conductivity can lead to a faster decay of sound within the material, impacting the duration and quality of sound transmission.</p>

- Q: Explain how the incorporation of titanium into aluminum alloys influences their properties and strength.

- <p>Adding titanium to aluminum alloys significantly enhances their mechanical properties and strength. Titanium increases the alloy's strength, hardness, and resistance to corrosion. It also improves the alloy's creep resistance, which is crucial for high-temperature applications. The addition of titanium refines the grain structure, leading to better ductility and toughness. Moreover, titanium helps to reduce the likelihood of stress-corrosion cracking, making the alloy more reliable in aggressive environments. Overall, titanium-aluminum alloys are stronger, more durable, and have a wider range of applications than pure aluminum or simple aluminum alloys.</p>

- Q: What are some typical combinations of metals that are used to create aluminum alloys?

- <p>Common alloys used for aluminum include 1000 series, which are nearly pure aluminum. The 2000 series, which contains copper, is known for its strength. The 3000 series, with manganese, is good for its formability. The 5000 series, which contains magnesium, offers good strength and welding characteristics. The 6000 series, which includes silicon and magnesium, is known for its strength and resistance to corrosion. Lastly, the 7000 series, which contains zinc, is the strongest and most commonly used for structural applications. These alloys are chosen for their specific properties such as strength, corrosion resistance, and workability, depending on the application.</p>

- Q: What limitations or precautions should be considered when using aluminum foil for cooking purposes?

- <p>Yes, there are restrictions on using aluminum foil for cooking. Avoid using it with acidic foods as it can react and release aluminum into the food. Also, refrain from using it at high temperatures, as it can melt and produce harmful fumes. Do not wrap food in aluminum foil and cook it in a microwave, as it can cause sparks and fires. Always ensure the foil is clean and free of any chemical residues from manufacturing.</p>

- Q: What are some environmentally friendly options that can replace aluminum in various applications?

- <p>Sustainable alternatives to aluminum include biodegradable materials like bamboo and hemp, which can be used in construction and packaging. Stainless steel is a recyclable metal that can replace aluminum in many applications due to its durability and strength. Recycled aluminum itself is a sustainable option as it requires less energy to produce than new aluminum. Additionally, magnesium and titanium are lightweight metals that can be used in place of aluminum in certain industries. It's important to consider the specific application when choosing an alternative, as each material has its own set of properties and environmental impacts.</p>

- Q: Explain the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in building materials due to its lightweight, high strength, and corrosion resistance. It's utilized in window frames, doors, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum's malleability allows it to be shaped into various forms, making it ideal for facades and decorative elements. It's also used in structural components like beams and columns, and in electrical wiring due to its excellent conductivity. Additionally, aluminum's sustainability makes it a preferred choice in green building practices, as it's recyclable and has a low environmental impact.</p>

- Q: What are some safety measures that should be taken into account when working with aluminum?

- <p>When working with aluminum, it's important to follow several safety precautions. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to protect against aluminum dust. Ensure proper ventilation to avoid inhaling aluminum dust or fumes. Use spark-resistant tools when cutting or welding aluminum to minimize the risk of fire. Keep a fire extinguisher nearby and be aware of the flammability of aluminum. Store aluminum in a dry, cool place to prevent it from reacting with moisture. Lastly, be cautious when handling aluminum alloys, as some can be more reactive or hazardous than pure aluminum.</p>

Send your message to us

Aluminum A1xxx Cold Rolled Circle Alloy CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords