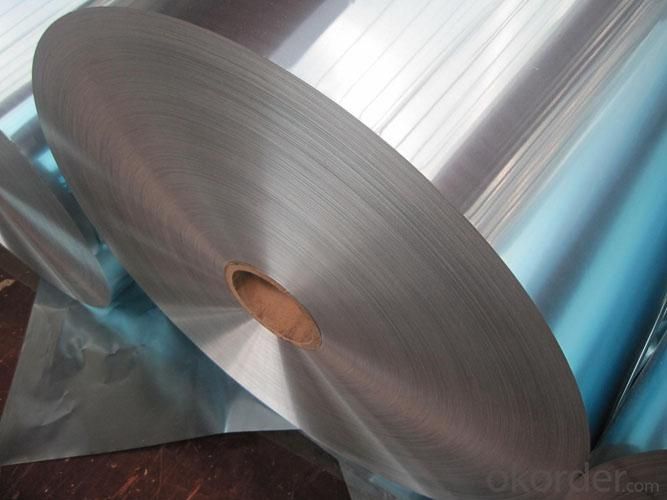

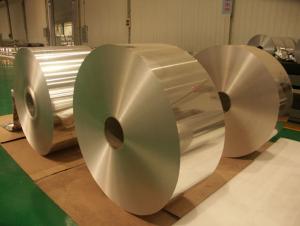

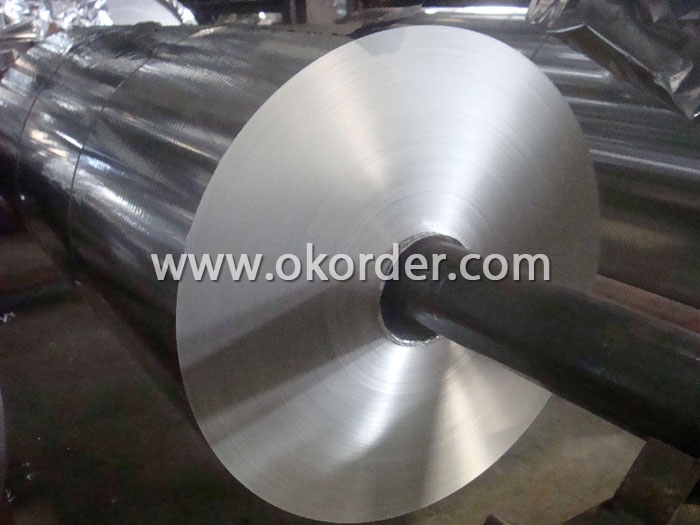

Aluminum Lamination Packaging Foilstock

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details of Aluminum Foilstock For Lamination Packaging Foil

|

Application: |

Cigarette Package, Aseptic Package, Pouches, Sachets |

|

Alloy: |

1235/8011/8079 |

|

Temper: |

O |

|

Thickness & Tolerance: |

0.006mm-0.009mm (±6%) |

|

Width & Tolerance: |

200mm-1650mm (±1mm) |

|

Mechanical Properties: |

Tensile Strength(U.T.S)≥40Mpa, Elongation≥1% |

|

Standard: |

GB/T3198 / ASTM-B209 / EN546 |

Usage/Application of Aluminum Foilstock For Lamination Packaging Foil

Used for flexible packaging, cigarette packages, aseptic packages, pouches, sachets.

Packaging & Delivery of Aluminum Foilstock For Lamination Packaging Foil

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Is it possible to utilize aluminum as a material for manufacturing solar cells?

- <p>Aluminum is not typically used to make solar cells due to its properties. Solar cells are usually made from materials like silicon, which is a semiconductor and can efficiently convert sunlight into electricity. Aluminum, being a good conductor, is used in the manufacturing process of solar cells for its electrical conductivity, but not as the active material that generates electricity. It is used in the form of aluminum paste in the back surface field of solar cells to create a conductive layer and in the frame to provide structural support. However, for the photovoltaic conversion process itself, other materials are more suitable.</p>

- Q: This question asks for methods to effectively clean aluminum surfaces without causing damage.

- <p>To clean aluminum surfaces effectively, use a mild detergent and warm water. Mix a few drops of dish soap with water in a bucket. Dip a soft cloth or sponge into the solution and gently wipe the aluminum surface. Avoid using abrasive materials or harsh chemicals, as they can scratch the surface. After cleaning, rinse with water and dry thoroughly to prevent water spots. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. Regular cleaning will help maintain the surface's appearance and prevent corrosion.</p>

- Q: Is it possible to create jewelry using pure aluminum?

- <p>Yes, pure aluminum can be used to make jewelry, but it's not commonly used for fine jewelry due to its lower value and potential for oxidation. While it is lightweight and affordable, it lacks the luster and durability of precious metals like gold, silver, or platinum. Aluminum can tarnish and may cause allergic reactions in some individuals. It is more commonly used in costume jewelry or for specific designs where its properties are advantageous.</p>

- Q: This question asks about the health effects of consuming aluminum on human health.

- <p>Aluminum consumption can have various effects on human health, though the extent of its impact is still a subject of debate among researchers. High levels of aluminum intake have been associated with neurological disorders, particularly Alzheimer's disease, although a direct causal link has not been definitively established. Aluminum can also interfere with bone health, potentially leading to osteoporosis, and may affect the kidneys, causing dysfunction. It is important to note that the human body naturally excretes aluminum, so moderate exposure is generally not harmful. However, excessive intake, especially over a long period, could pose health risks.</p>

- Q: Is aluminum a suitable material for use in the electronics manufacturing industry?

- <p>Yes, aluminum is widely used in electronics manufacturing due to its excellent electrical conductivity, lightweight nature, and resistance to corrosion. It is commonly used in various electronic components such as heat sinks, capacitors, and wiring. Aluminum's malleability also allows it to be easily shaped into different forms, making it versatile for manufacturing purposes. Additionally, it is cost-effective and abundant, which further contributes to its popularity in the electronics industry.</p>

- Q: This question asks about the impact of adding magnesium to aluminum alloys and how it changes their characteristics.

- <p>The addition of magnesium to aluminum alloys significantly improves their mechanical properties, particularly strength and rigidity. Magnesium enhances the alloy's resistance to corrosion and increases its formability. It also contributes to better weldability and reduces the likelihood of hot cracking during the welding process. However, the addition of magnesium can also lead to a decrease in electrical conductivity and may increase the alloy's susceptibility to stress corrosion cracking. The overall effect of magnesium on aluminum alloys is to create a material that is lighter, stronger, and more resistant to environmental degradation, making it suitable for various applications in the aerospace, automotive, and construction industries.</p>

- Q: Explain the natural relationship between aluminum and magnesium, focusing on their abundance and reactivity in the Earth's crust.

- <p>Aluminum and magnesium are both abundant elements in the Earth's crust, with aluminum being the most abundant metal and magnesium being the eighth most abundant element overall. They are often found in close association within the same minerals, such as in aluminosilicates and some carbonates. Both elements are highly reactive, forming compounds readily with oxygen to create oxides and silicates. However, they differ in their reactivity with water; aluminum forms a protective oxide layer that prevents further reaction, while magnesium reacts more readily with water to form magnesium hydroxide. This difference in reactivity influences their distribution and the types of compounds they form in nature.</p>

- Q: I would like to ask where there is a need for these minerals? How much is it per ton?

- Liaoning. Do you need silica there? If necessary, please leave your contact informationChasing the answerWe also have a lot here, you can go to the glass factory near you to contact, it is worthless, not enough freight

- Q: This question asks for methods to prevent the corrosion of pure aluminum when exposed to environmental factors.

- <p>To prevent corrosion of pure aluminum in the environment, one can apply protective coatings such as paints or anodizing, which forms a dense oxide layer on the surface. Additionally, using aluminum alloys that contain elements like copper, magnesium, and silicon can enhance resistance to corrosion. Regular cleaning and maintenance to remove contaminants that may initiate corrosion are also important. In extreme environments, cathodic protection or the use of inhibitors can be employed to further protect aluminum from corrosion.</p>

- Q: This question asks for the specific temperature at which aluminum oxide transitions from a solid to a liquid state.

- <p>The melting point of aluminum oxide (Al2O3) is approximately 2072掳C (3767.6掳F). It is a high melting point due to the strong ionic bonds between aluminum and oxygen atoms in the crystal structure. This high melting point makes aluminum oxide a common material in high-temperature applications such as refractory materials and abrasives.</p>

Send your message to us

Aluminum Lamination Packaging Foilstock

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Tons m.t.

- Supply Capability:

- 10000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords