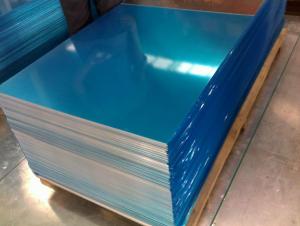

0.08mm Aluminum Sign Sheets with Heat Sealing Aluminum Foil Tapes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packaging & Delivery

| Packaging Details: | Packaging, marking, transport and storage Marking Adhesive tape per box should have the following marks: a) Producer name and address; b) Product name and specifications; c) Quantity and weight; d) Date of manufacture or batch number of production; e) Pressure prevention, moisture-roof and sunscreen signs; f) Expiration date. g) If meeting the RoHS requirements, the product packaging is RoHS labeled. Packaging The product is packaged by use of corrugated boxes, and plastic bags are packa |

| Delivery Detail: | AS SOON AS POSSIBLE |

Specifications

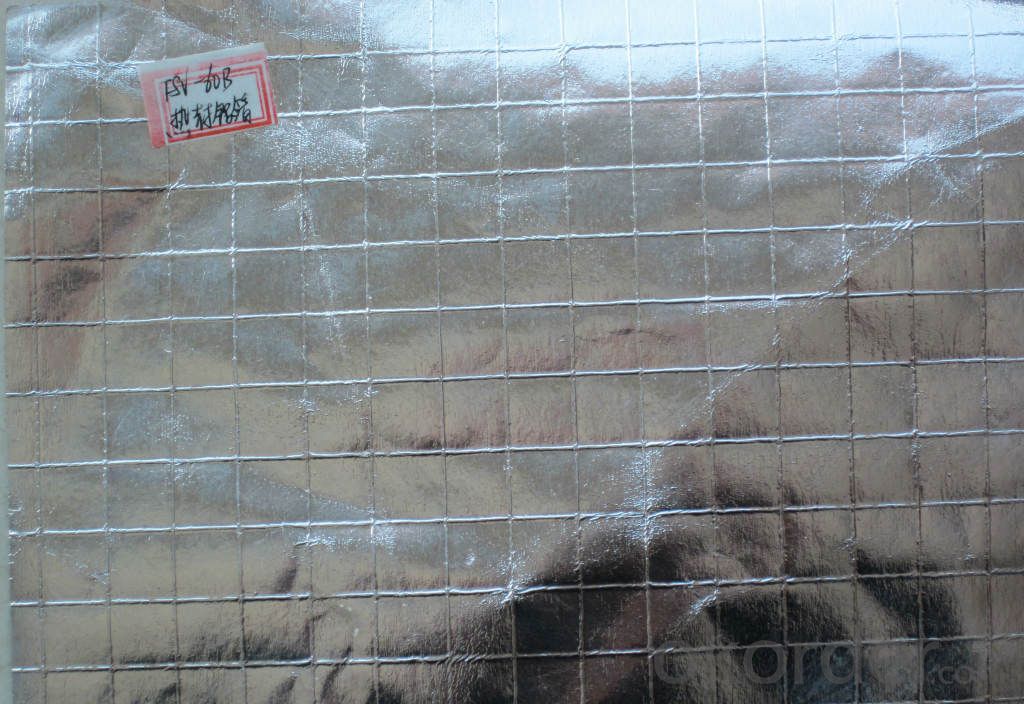

applicable to encapsulate the evaporation pipelines for refrigerator, freezer and other refrigeration systems.

Aluminum foil tapes with heat sealing films

Aluminum foil tapes with heat sealing films

CODE | Acrylic Adhesive | Category | Thickness | Initial Stickiness | 180°Peeling Strength | Permanent Adhesion | Tensile Strength | Polyurethane Foam Adhesive Rate |

BLAMT-301 | Water-Based | Bopp | ≥0.07mm | ≥15# | 4n/cm | ≥24h | ≥25n/cm | |

BLAMT-302 | Oily | Bopp | ≥0.07mm | ≥15# | 6n/cm | ≥24h | ≥25n/cm | |

BLAMT-303 | Oily | Pe | ≥0.07mm | 7.5n/cm | ≥24h | ≥25n/cm | ≥60% | |

BLAMT-304 | Oily | Bopp | ≥0.07mm | 7.5n/cm | ≥24h | ≥25n/cm | ≥60% |

Aluminum foil coated adhesive tape

Composition and characteristics:

with aluminum foil as the base material, the back of the base material is coated with a layer of polypropylene (BOPP) or polyethylene (PE) film and coated with special release agent, and the front face is coated with factice or glue.

Main usage:

applied for encapsulating and winding evaporation pipelines for refrigerator, freezer and other refrigeration equipment, this tape has outstanding sealing and heat preservation performance, and it is easy and convenient to operate. The back of the products 303 and 304 is applied with special release agent and then they can be connected with polyurethane foam, so the heat sealing performance is more outstanding.

The above parameters are for reference only,

and special requirements can be applicable according to actual demands of users

- Q: Can aluminum sheets be perforated?

- Yes, aluminum sheets can be perforated. Perforation is a process that involves creating holes or punctures in a material, and it can be done on various types of metals, including aluminum.

- Q: Are aluminum sheets suitable for signage?

- Yes, aluminum sheets are highly suitable for signage. Aluminum is a versatile material that offers a range of benefits for signage applications. It is lightweight, durable, and resistant to corrosion, making it ideal for both indoor and outdoor signage. Aluminum sheets can withstand harsh weather conditions, including rain, snow, and UV exposure, without deteriorating or fading. They are also easy to work with, allowing for a variety of customization options such as embossing, engraving, and digital printing. Moreover, aluminum sheets are cost-effective and have a long lifespan, ensuring that signage remains in excellent condition for extended periods. Overall, aluminum sheets are a popular choice for signage due to their durability, versatility, and aesthetic appeal.

- Q: Can aluminum sheets be easily shaped or bent?

- Yes, aluminum sheets can be easily shaped or bent. Aluminum is known for its excellent malleability and ductility, which allows it to be easily formed into various shapes and bends. It can be manipulated using a variety of techniques such as rolling, pressing, or even using hand tools. The malleability of aluminum makes it a preferred choice in industries such as automotive, aerospace, and construction, where it is commonly used in the production of parts and structures that require complex shapes and bends. Additionally, aluminum's lightweight and corrosion-resistant properties further contribute to its suitability for shaping and bending processes.

- Q: This question asks about the distinctions between aluminum sheets that are produced domestically versus those that are imported.

- <p>Yes, there can be differences between domestic and imported aluminum sheets. These differences may include quality standards, material composition, thickness, surface finish, and price. Domestic sheets are often produced to meet local standards and regulations, while imported sheets may adhere to different international standards. The manufacturing process and raw materials used can also vary, leading to differences in durability, strength, and workability. Additionally, imported sheets might have different certifications or come from countries with lower production costs, which can affect the price. However, it's important to note that not all imported aluminum sheets are of lower quality; some may be of higher quality or have specific characteristics that are not available domestically.</p>

- Q: The user is asking if it's possible to substitute recycled aluminum sheets for new ones in a project or application.

- <p>Yes, you can use recycled aluminum sheets instead of new ones in many applications. Recycled aluminum maintains the same properties as new aluminum, making it suitable for construction, manufacturing, and various other uses. It's also more sustainable and cost-effective. However, it's important to ensure that the recycled aluminum meets the required specifications and quality standards for your specific project to avoid any structural or performance issues.</p>

- Q: Can aluminum sheets be used for sign making?

- Yes, aluminum sheets can be used for sign making. Aluminum is a commonly used material for making signs due to its durability, lightweight nature, and resistance to rust and corrosion. It is a versatile material that can be easily cut, shaped, and printed on, making it suitable for various sign making applications.

- Q: What industries use aluminum sheets?

- Aluminum sheets find extensive use across various industries due to their numerous advantageous properties. The automotive industry, in particular, heavily relies on aluminum sheets. With its lightweight yet strong composition, aluminum proves to be an ideal material for manufacturing car bodies and parts. This, in turn, helps reduce vehicle weight, improving fuel efficiency and curbing emissions. Similarly, the aerospace industry also heavily depends on aluminum sheets owing to their high strength-to-weight ratio. Aluminum's suitability for aircraft construction is evident in its usage for airplane frames, wings, and fuselages. The lightweight nature of aluminum contributes to increased fuel efficiency and enables larger payloads. The construction industry is another major consumer of aluminum sheets. Thanks to its corrosion resistance and durability, aluminum serves as an excellent choice for building materials. It finds common application in roofing, siding, windows, doors, and structural components for both residential and commercial construction projects. In the packaging industry, aluminum sheets are extensively utilized for manufacturing beverage cans. Aluminum cans provide a lightweight and portable packaging solution while ensuring product freshness and protection against light and air. Additionally, the electrical industry benefits from the use of aluminum sheets. Aluminum's excellent conductivity makes it well-suited for electrical transmission lines, cables, and wiring. It also finds application in the production of heat sinks and electrical enclosures. Marine industry applications involve aluminum sheets for boat building and ship construction due to their resistance to corrosion in saltwater environments. Furthermore, aluminum sheets play a significant role in the manufacturing of household appliances, such as refrigerators, ovens, and washing machines, owing to their durability, lightweight nature, and heat conductivity properties. In conclusion, the versatility, strength, lightweight nature, and corrosion resistance of aluminum sheets make them indispensable across a wide range of industries, including automotive, aerospace, construction, packaging, electrical, marine, and household appliances.

- Q: I just bought a cheap brand of pop tarts. One of the listed ingredients under Leavening is, sodium aluminum. I don't think Wal-Mart will take back the box, so should I just throw the whole box of 16, away. Or is the proportion of aluminum in the product so minute, that it will not make a difference to my health? Thanks.

- It's actually Sodium Aluminum Phosphate. It's used as a preservative in a lot of food actually. It's not exactly good for you, but it's really no more harmful than any other preservative. So basically, it's unhealthy, but you're not gonna die from eating them. EDIT: Yes I realize that Aluminum has been linked to Alzheimer's disease, but this isn't Aluminum. Aluminum is an element. This is Sodium Aluminum Phosphate. A completely different substance. When an element bonds with another element (or two) often its properties completely change. I think you'd be surprised to learn that Sodium by itself, is not only horribly volatile (it will explode in water) and will kill you if you ingested it. Iodine is also poisonous in fairly moderate doses. But when the two are bonded together (sodium iodide) it becomes an essential nutrient to the body.

- Q: Can aluminum sheets be used for electronic devices?

- Yes, aluminum sheets can be used for electronic devices. Aluminum is a widely used material in the electronics industry due to its excellent conductivity, low weight, and high durability. It is commonly used for various applications such as housing for electronic components, heat sinks, and electrical connectors. Aluminum sheets can be easily formed into different shapes and sizes, making them suitable for a wide range of electronic devices. Additionally, aluminum is a cost-effective material, making it an attractive choice for manufacturers in the electronics industry.

- Q: Are aluminum sheets suitable for chemical storage tanks?

- No, aluminum sheets are not suitable for chemical storage tanks as aluminum is highly reactive and can corrode when in contact with certain chemicals.

Send your message to us

0.08mm Aluminum Sign Sheets with Heat Sealing Aluminum Foil Tapes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords