Blister Aluminum Foil Hot Rolled Checkered Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminum Foil Hot Rolled Checkered Steel Plate:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of Aluminum Foil Hot Rolled Checkered Steel Plate

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

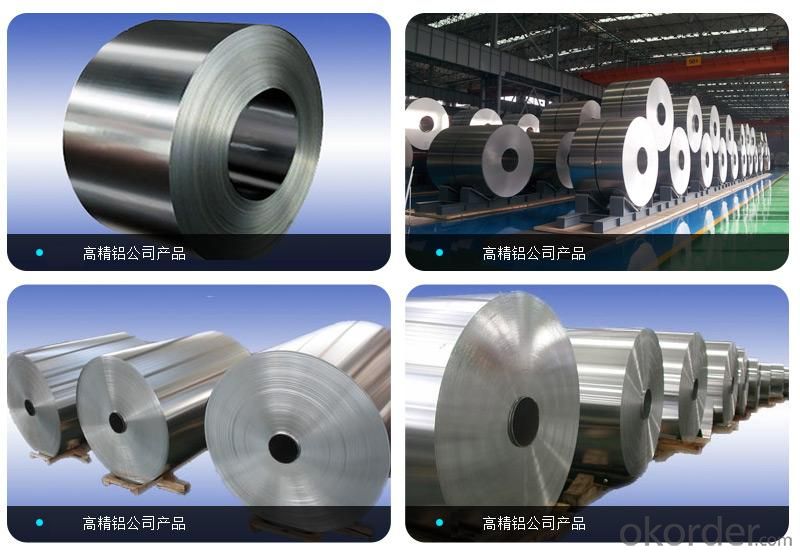

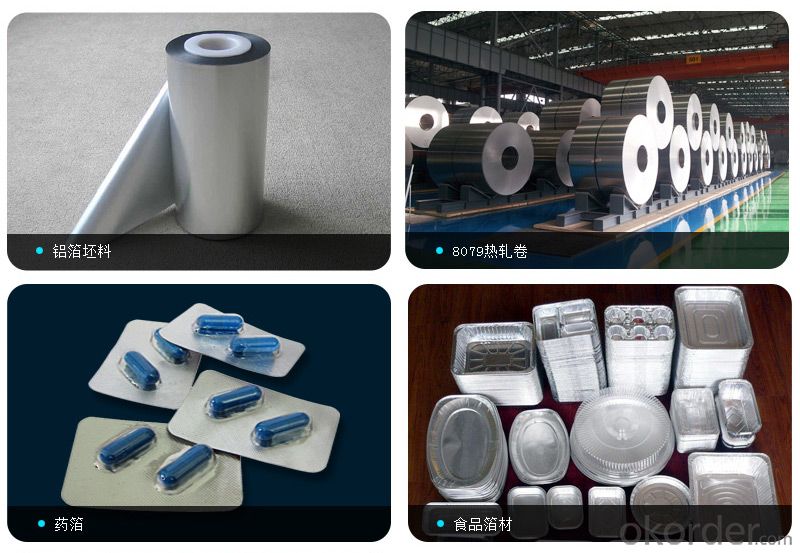

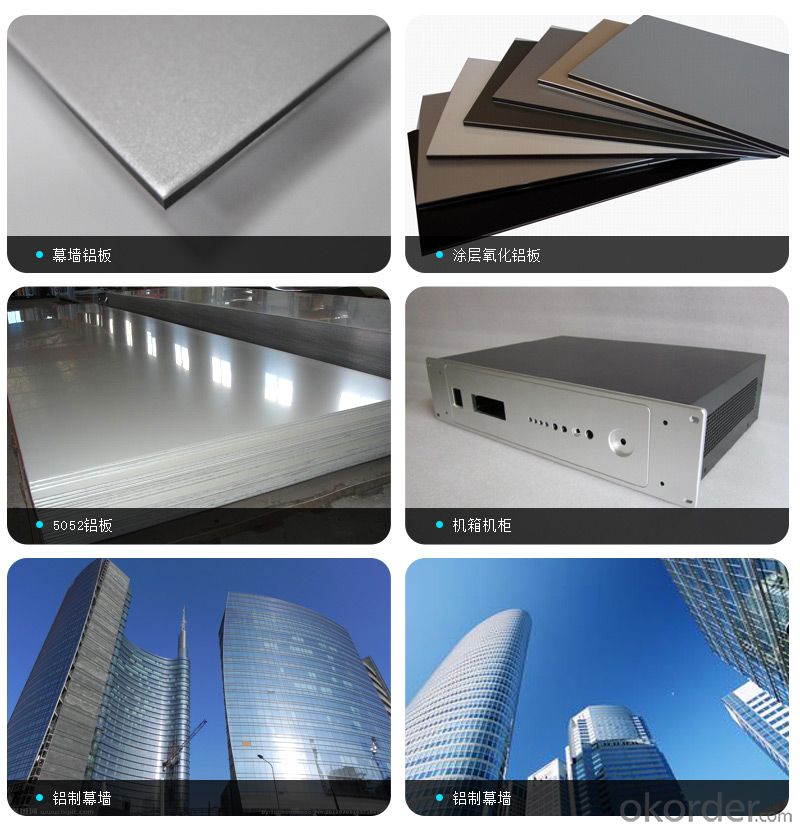

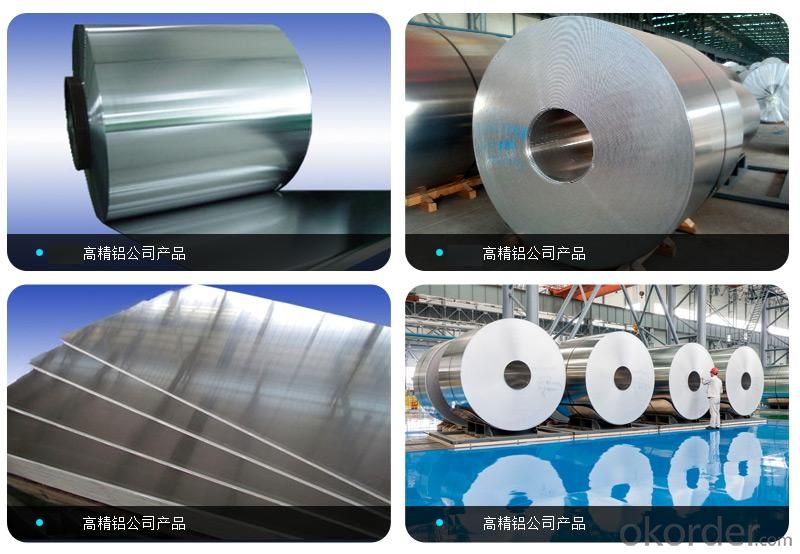

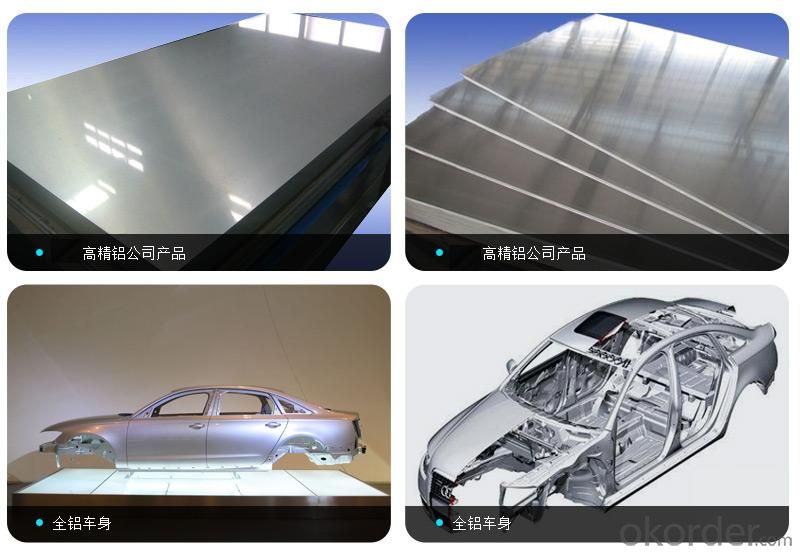

Images of the Aluminum Foil Hot Rolled Checkered Steel Plate:

Aluminum Foil Hot Rolled Checkered Steel Plate Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

Production Aluminum Foil Hot Rolled Checkered Steel Plate:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

- Q: Rank the following from lowest to highest SECOND ionization energyNa-, Mg-, Al- Explain your answer.

- They're sweet potatoes, bake them for about 30-40 minutes.

- Q: how many unpaired electrons are in the following ionsAl3+ and Cl-

- share your weight loss goals with your friends and family make it a positive life change and ask for their encouragement

- Q: A copper rod and an aluminum rod of equal diameter are joined end to end in good thermal contact. The temperature of the free end of the copper rod is held constant at 100°C, and that of the far end of the aluminum rod is held at 0°C. If the copper rod is 0.88 m long, what must be the length of the aluminum rod so that the temperature at the junction is 50°C?

- This is a good example of a heat transfer problem.

- Q: A gold cathode with work function 5.1 eV is illuminated with light of wavelength 250 nmIt is found that the photoelectron current is zero when the anode-cathode potential difference is zeroWould the current change if the1)light intensity is doubled? Explain your answer.2)anode-cathode potential difference is increased to 5.5 V? Justify your answer.3)cathode is changed to aluminum (work function 4.3 eV)? Explain your answer.

- 1) current increases in generalEmitted electrons have some initial k.eand they move towards the anode to give rise to a currentAs the intensity increases the number of electrons emitted increase and hence the current increasesIn the particular case hf hc/λ 6.625x10^-34x3x10^8x6.624x10^18/250x10^-4.96 eV , which is less than the work function 5.1 eVHence there is no photoelectric emissionSo no current 2) Increases to a saturation value in generalIncrease in the anode cathode potential increases the speed of the electrons or the noof electrons crossing unit area per second, hence the current increasesBeyond a certain value of the accelerating potential the velocity of the electrons becomes maximum and cannot increase further , and the current reaches a saturation valueIn the above case since there is no photoelectric current no question change in current3)The photoelectric equation is hf W + mv^2/2 So in general for a given frequency if the work function W is smaller or decreased then the k.eof the electrons is more and the speed is moreHence the current increasesIn the above problem the work function is changed to 4.3 eV which is less than hf 4.96 eVHence photo electrons are generated and there is a current even in the absence of accelerating potential.

- Q: i love to eat tiramisubut as a Muslim i am forbidden to take alcoholi want a delicious one please.

- Making an internal combustion engine is not a job for individuals.It is normally done of by a team of specialist in various fields, with means and resources.The team has vast experience and sit on a bank of knowledge and informationNormally, a newly designed engine is based on old successful modelsIn your effort you would neither save nor get an acceptably working engineI think you will be well advised to abandon your ideas and buy a reputable massly producd engine.

- Q: When you cook chicken and stuffAnd if you do doyou reuse them?

- I use them when I'm going to be canning large amounts of a food like beef stewI only do that when I find a great sale on beefI'll be making up a batch come Thursday since they have whole bottom round on sale here for $1.79 a poundI bought a couple of the large disposable roasters last year and have used them about a dozen times Because of their shape and the fact that they are really just super heavy foil they can be very difficult to clean by handThey tend to turn colors in your dishwasher if you have a dry cycle on it but it doesn't hurt them anyI'll get another three or four uses out of my current ones before I replace them.

- Q: The cutting part of my can opener - a disc looking think - has gunk built up on it, and its so dried out and tough I can't even scrape if off with a toothpick! Gross!How do I get it off there without damaging the can opener?

- What you need to buy is Steel, Carben SteelYou want a sword? go for 1055 carbon steel or 1065 carbon steel, 1065 is what i useYou need a Grinder to grind the metal down, and to sharpen it, you need wood for a handle so you should drill holes into the tang of the sword and bolt it inthis is a very simplistic sword, hell you might even call it a machete, If you need help Just comment on my post, ill respond.

- Q: The diagram at the right shows a metal sphere attached to the top of an insulating standthe metal sphere contains an excess of electrons and is thus chargeda student holds various objects in her hand and touches the object to the spherewhich of the following objects below would allow charge to throw it when the student touches the object to the sphere?aa plastic strawba piece of paperca steel house keyda metal paper clipea strip of aluminum foilThe diagram is just a circle with 12 quot;-quot; circling the inside

- Get him a grammar lesson and one on manners.

- Q: I need help in making a simple but clear and nice looking 3D human heart that I can stick onto a foam board so I can label it on therePlease help! Just link me or send me videos or something.I'm able to use things like foam, clay etc Thanks xo

- The human heart is a complex thing to sculpt and for your purpose I would probably use polymer clay starting with a hollow shape around a wad of aluminum foil so I could have a softer red body on which to lay darker red arteries and bluer veins for function I don't consider foam all that easy to carve into this kind of shape and when done you would have to color code it Maybe the second choice, for your purpose would be to pick your view of the heart and use paper mache to make a half shell over a bowl or round coffee cup/custard cup with the major arteries and veins being added tubes of paperThen paint the surface when dry.

Send your message to us

Blister Aluminum Foil Hot Rolled Checkered Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords