Sams Aluminum Foil Hot Rolled Checkered Steel Plate with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Specification of Hot Rolled Checkered Steel Plate with Best Quality:

1.Advantages of Hot Rolled Checkered Steel Plate from China CNBM:

a) The unfairness of our checkered steel sheet must be less than 10mm each meter

b) The surface of our hot rolled checkered steel plate is free from bubble, scab, crack, fold, edge delamination and so on.

c) The height of our hot rolled checkered steel plate will be maintained between 0.2~0.3 times to thickness of steel substrate, but more than 0.5mm at least.

2. Other details of Hot Rolled Checkered Steel Plate from China CNBM

Standard | GB T 3277, DIN 5922 |

Grade | Q235, S235JR |

Thickness | 2.5-8.0mm |

Width | 1000-1600mm |

Length | 4000-8000mm |

3. The regular sections we provide are shown in the below table:

Base Thickness(MM) | Allowed Tolerance of Base Thickness(%) | Theoretical Mass (KG/M²) | ||

The Pattern | ||||

Rhombus | Beam | Pea | ||

2.5 | ±0.3 | 21.6 | 21.3 | 21.1 |

3.0 | ±0.3 | 25.6 | 24.4 | 24.3 |

3.5 | ±0.3 | 29.5 | 28.4 | 28.3 |

4.0 | ±0.4 | 33.4 | 32.4 | 32.3 |

4.5 | ±0.4 | 37.3 | 36.4 | 36.2 |

5.0 | 0.4~-0.5 | 42.3 | 40.5 | 40.2 |

5.5 | 0.4~-0.5 | 46.2 | 44.3 | 44.1 |

6.0 | 0.5~-0.6 | 50.1 | 48.4 | 48.1 |

7.0 | 0.6~-0.7 | 59.0 | 52.5 | 52.4 |

8.0 | 0.7~-0.8 | 66.8 | 56.4 | 56.2 |

4. Chemical Composition of Hot Rolled Checkered Steel Plate from China CNBM

Chemical Composition | ||||||||||

C | Si | Mn | P | S | ||||||

Q345B | ≤0.20 | ≤0.55 | 1.00-1.60 | ≤0.040 | ≤0.040 | |||||

Q345C | ≤0.20 | ≤0.55 | 1.00-1.60 | ≤0.035 | ≤0.035 | |||||

Q345D | ≤0.18 | ≤0.55 | 1.00-1.60 | ≤0.030 | ≤0.030 | |||||

Note: Here, we just take the hot rolled checkered steel sheet according to Q345B, Q345C and Q345D as example. We are also able to provide SGS test report for checkered steel sheet as per other material

Package & Delivery of Hot Rolled Checkered Steel Plate with Best Quality:

1. The items to be prepared for packing include: narrow steel strip, crude steel belt or edge angle steel, kraft paper or galvanized sheet.

2. The hot rolled checkered steel plate should be wrapped with kraft paper or galvanized sheet ouside, and it should be bundled with narrow steel strip, three or two narrow steel strip in longitudinal direction,and the other three or two strips in transverse direction. Furthermore, in order to fix the hot rolled checkered steel plate and avoid the strip at edge shall be broken, the crude steel belt cut into square should be put under the narrow steel strip on the edge. Of course, the hot rolled checkered steel plate could be bundled without kraft paper or galvanized sheet. It depends on customer’s requirement.

3. In consideration of the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4. All in all, we could do in accordance with customer's request.

Production Flow of Hot Rolled Checkered Steel Plate with Best Quality:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

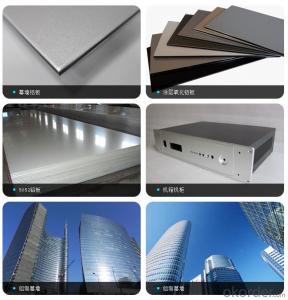

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

- Q: A round rod of aluminium 150 mm long and 24 mm in diameterdeforms elastically under a load of 20 kN by an amount of 95μmCalculate the following:-a)the tensile stress (σ) in the rod,b)the elastic strain (ε) in the rod,c)the modulus of elasticity (E Young’s modulus) of aluminium.

- it fairly is the least perplexing tastiest way i understandGet a bottle of choose Bone Italian Salad Dressing and marinate the steak in a single dayvia fact the steak chefs (on the grill, you have too do it on the grill(that's a ethical crucial)) you may brush on some greater salad dresing to maintain it juicybelieve me.very yummy steak without choose of sauce!

- Q: Is it possible to use aluminum foil as a wrapper for a burrito?

- <p>While it's technically possible to use aluminum foil to wrap a burrito, it's not recommended. Aluminum foil is not designed for food handling and can tear easily, leading to a messy situation. Instead, use a tortilla to wrap your burrito, which is the traditional and practical method. If you need to keep it warm for transport, consider using a heat-resistant food wrap or a clean cloth napkin.</p>

- Q: What material is the casing made of?

- Where Does Jessie Take Place

- Q: This is such a frustrating problem! Why aren't there better dryer designs? Does anyone make a decent vent hook-up, or aluminum hose that stays in place and don't fall out in the back of the wall? Anyone have something that actually stays in place? I don't want laundry detergent scented air inside the house.

- I haven't had a problem with thisThe trouble you may be having is that since the vent through the wall is behind the dryer, you can't easily line up the dryer vent and the vent through the wall once the dryer is partway in placeWhat I have done is get some expandable aluminum ducting, attach it to the wall vent and the dryer while it's expanded, then push the dryer into place until the ducting has squashed up as short as it will goIt's bit tricky to do, measure carefully, but it worksIf, on the other hand, you can get at the back of the dryer easily, then use aluminum duct tape to seal the edges where the ducts meet, the very shiny kind of tape made for heating ducts, not the fibre-based stuff we all use for everythingIt will take heat, is very very sticky and it's like tin foil, so you can get it to fill little spaces and mold it around edgesBig hose clamps will do the same thing.

- Q: I just bought brachs carmel candiesdo you melt them on a stoveDo you add evaporated milk? HELP HELP HELP!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

- 6 Granny Smith apples 6 wooden sticks 1 (14 ounce) package individually wrapped caramels, unwrapped 2 tablespoons water 1/2 teaspoon vanilla extract Insert wooden sticks 3/4 of the way into the stem end of each applePlace apples on a cookie sheet covered with lightly greased aluminum foilCombine caramels and water in a saucepan over low heatCook, stirring often, until caramel melts and is smoothDip each apple into the caramel and gently run apples around insides of saucepan to scrape off some of the caramelScrape excess caramel from the apple bottoms using the side of the saucepanPlace on the aluminum foil and chill until ready to serve.

- Q: I have a 4.6 pound bottom round roast (beef)How do I cook it? What temperature and how long in the oven? We like it medium rare.

- Why did you ask such a hard question!!?!!?!?!?!!! but plastic wrap because you can wrap stuff up like tin foil and you put cookies on a plate instead of wax paper! So.

- Q: Is it okay to bake an apple pie without a top crust?

- Make a French Apple Pie insteadThis uses a streusel topping in place of a 2nd crustIt's my absolute favorite kind! Try this recipe1 (9 inch) unbaked pie crust 3/4 cup sugar 1/4 cup flour 1/2 teaspoon ground nutmeg 1 teaspoon cinnamon 6 cups thinly sliced tart apples (about 6 medium) Topping 1 cup flour 1/2 cup firm margarine or butter 1 1/2 teaspoons cinnamon 1/2 cup firmly packed brown sugar -Heat oven to 425°FIn a large bowl mix sugar, flour, nutmeg and cinnamonStir in apples and mix until apples are coated in sugar mixture and ingredients are all completely moistenedPour apple filling into prepared pie crustTopping: Mix flour, brown sugar, cinnamon and margarine until well mixed and crumblyPour onto pie fillingBake for 50 minutesCover topping with aluminum foil during the last 10-20 minutes of bakingThe topping should be browned and crisp and the bottom crust should be goldenEnjoy!

- Q: Aluminum becomes a positive ionWould Calcium and Aluminum be likely to form a compound?

- Yup thats the life in the projectsI went to saracuyse NY on a family reunionI stayed with me aunt in the projects, i seen all kind of drud deals and two people were stabbed and one was shotI was 14 yrs old when this happend so it was like 10 years agoya im a white boy but my mom has a lot of black people in her familytell me i wasnt scared, lets just say i pretty much hugged my cousin the whole time i was there

- Q: I've dyed my hair before so I know how to do itToday I got dark brown hair dye and blonde hair dyeI want to put in blonde highlightsShould I put in the dye together and wrap the highlights in aluminium foil, or dye my hair dark brown and then wait until it dries, then put the highlights in? Please help, experienced people only please.

- Dye your hair first and wait until your hair is dryThen, section off your hair by layersMix the blonde dye like a pasteIt is best if you have a brush to do this withPick a small section and put it on the tin foilUse the brush and dip it into the pasteAs close to your roots as you can, paint the dye onto the sectionWith the brush, curve your hair so all the hair in the section is on the tin and covered with dyeWhen you're done with the section, fold the foil in half, and then in half againContinue this until you have a whole head of foilLeave the foil in your hair for about half an hourRemove the foil and wash off the dyeYou might need a little help to do the hair on the back of your headThis takes a lot of patience if you're doing it yourselfI highly recommend you wait 4-6 weeks prior to dying or highlighting, as doing it all at once could be VERY damaging to your hairUsing hair dye specifically designed to make highlights, might give you better resultsBest of luck!

- Q: Is it safe to use aluminum foil to wrap frozen vegetables?

- <p>Yes, you can use aluminum foil to wrap frozen vegetables. Aluminum foil is a good conductor of heat, which can help to cook the vegetables evenly. It also prevents freezer burn by creating a barrier that keeps air away from the food. However, it's important to ensure the foil is food-grade and that it doesn't come into direct contact with the vegetables, as some vegetables can react with aluminum. Always check the integrity of the foil to avoid any tearing or punctures that could allow freezer burn to occur.</p>

Send your message to us

Sams Aluminum Foil Hot Rolled Checkered Steel Plate with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords