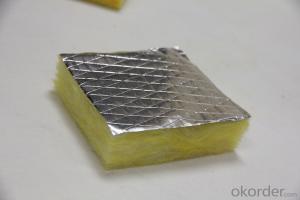

Aluminum Foil Facing Rock Wool Board for Wall Partition Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 700 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. INTRODUCTION

CMAX ROCK WOOL are widely used in public, commercial an residential building as well as industrial plants, for applications such as roofing, external wall, partion wall and floating floor to provide fire protection, thermal insulation, acoustic control and condensation control.

2. FEATURES

● Thermal Insulation

● Fire Safety

● Acoustic Control

● No Corrosion

● Environmental friendly

● Moisture Resistance

● Energy Conservation & Emissions Reduction

3. CMAX ROCK WOOL BLANKET & BOARD STANDARD SIZE

PRODUCT | BLANKET | BOARD |

Density(Kg/m3) | 60-100 | 40-200 |

Thickness(mm) | 30-150 | 30-100 |

Size:L*W(mm) | 1200*3000-6000 | 600*1200 |

Remark:

Other sizes are available unpon request. Facing materials can be applied unpon request.

4. PRODUCTION THECHNOLOGY

CMAX rock wool is made from natural rocks such as basalt and limestone. The rocks are melted in a cupolaat temperature of >1450℃, and the molten lava is fiberized by a spinner. The inorganic fibers are bondedtogether using a thermosetting resin to form the final product which is cut into suitable sizes for easyhandling and installation. Other products such as wired blanket, pipe cover or faced products are producedby secondary process

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 40 working days can be served.

4.Packing,Tranportation and Storage

Product is packed in polythene plastic shrink film or plastic bag. During transportation and storage, please keep product away from moisture and compressive deformation.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the precautions to be aware of when using aluminum foil in the kitchen?

- <p>When using aluminum foil in the kitchen, it's important to avoid direct contact with acidic or alkaline foods as it may react and contaminate the food. Do not use it in broilers or ovens above 450掳F (232掳C), as it can melt and release harmful fumes. Avoid wrapping food in aluminum foil for extended periods, especially at high temperatures, as it may lead to the foil breaking down and leaching aluminum into the food. Always check for any tears or punctures in the foil to prevent food from coming into contact with the cooking surface directly.</p>

- Q: How should aluminum foil be stored when not in use to maintain its facing orientation?

- <p>The best way to store aluminum foil is to keep it in its original box or a resealable container with the shiny side facing outward. This prevents the foil from sticking together and makes it easier to use. If the box is not available, you can also use a rubber band to wrap the foil around a cardboard tube, ensuring the shiny side is facing out, or place it in a container with a paper towel on the bottom to prevent sticking.</p>

- Q: Is it safe to use recycled aluminum foil for cooking or baking purposes?

- <p>Recycled aluminum foil facing is not recommended for cooking or baking. While aluminum foil itself is safe for cooking and can be used to cover dishes or line baking sheets, recycled foil may have impurities or contaminants from previous uses. It may also be thinner and less durable, leading to potential tearing or puncturing, which can result in food contamination. For safety and food quality, it's best to use new, high-quality aluminum foil for cooking and baking.</p>

- Q: This question asks for a comparison between aluminum foil facing and other types of metal foils, highlighting their differences.

- <p>Aluminum foil facing is distinct from other metal foils due to its specific properties. It is lightweight, highly reflective, and offers excellent heat conductivity, making it ideal for insulation and cooking applications. Unlike other metal foils, aluminum foil is non-toxic and can be safely used in food packaging and preparation. It is also corrosion-resistant and has a lower melting point compared to metals like steel or copper, which affects its usability in various industries. Additionally, aluminum foil is more affordable and widely available than some other metal foils, contributing to its popularity in everyday use.</p>

- Q: What are the considerations or safety measures to be aware of when using aluminum foil with a nonstick coating?

- <p>When using aluminum foil with a nonstick coating, it's important to avoid exposing it to high heat as the nonstick layer can degrade and release harmful fumes. Do not use it in broilers, on grills, or in the oven at temperatures exceeding 400掳F (204掳C). Additionally, refrain from cutting or puncturing the foil, as this can damage the nonstick surface. Avoid using metal utensils that might scratch the coating. Always follow the manufacturer's guidelines for safe use and temperature limits.</p>

- Q: Is it safe and effective to use aluminum foil with a reflective side to wrap vegetables when grilling?

- <p>Yes, you can use aluminum foil facing to wrap vegetables for grilling. Aluminum foil helps to retain moisture and heat, ensuring that the vegetables cook evenly and remain tender. The reflective side of the foil can also help to distribute heat more evenly. However, be cautious not to let the foil touch the flame directly, as it can cause flare-ups. Make sure to poke some holes in the foil to allow steam to escape and prevent the vegetables from becoming too soggy.</p>

- Q: What is the most suitable material for food packaging that ensures safety and is also eco-friendly?

- <p>The best material for food packaging that is both safe and environmentally friendly is biodegradable or compostable material. Materials such as PLA (Polylactic Acid), made from renewable resources like corn starch, and paper-based packaging are preferred. They are non-toxic, compostable, and reduce plastic waste. Additionally, materials like glass and metal can be recycled and are also considered safe for food contact. However, it's crucial to consider the entire lifecycle of the packaging to ensure it's truly sustainable.</p>

- Q: Is it possible to use aluminum foil as a cooking surface? If yes, what are the methods of using it?

- <p>Yes, aluminum foil can be used for cooking. It's commonly used for wrapping foods to retain moisture and heat, such as when baking potatoes or fish. You can also create a foil packet (en papillote) by placing food in the center of a large piece of foil, seasoning it, and then folding the foil to seal the edges. This method steams the food, keeping it moist. For grilling, use heavy-duty foil to prevent tearing and place food directly on it. Remember, avoid using aluminum foil with acidic foods as it can react and leach aluminum into the food.</p>

- Q: Is it safe to use aluminum foil facing to wrap hot food?

- <p>Yes, you can use aluminum foil facing to wrap hot food. Aluminum foil is a safe and common material for food packaging, especially for wrapping and cooking food in the oven. It's important to ensure that the foil is food-grade and not damaged or punctured, as this could lead to contamination. Additionally, avoid wrapping acidic foods at high temperatures as this can cause the foil to react and potentially release aluminum into the food. When in doubt, check the manufacturer's guidelines for safe use with hot foods.</p>

- Q: Is it possible to use aluminum foil facing in the creation of desserts?

- <p>Yes, aluminum foil facing can be used for making desserts, particularly for baking purposes. It is often used to line baking sheets or molds to prevent desserts from sticking, making them easier to remove after baking. It also helps in maintaining the shape and presentation of the dessert. However, it's important to ensure that the foil does not come into direct contact with the dessert if it's not oven-safe, as this could lead to contamination or uneven cooking. Always follow the manufacturer's guidelines for the specific type of aluminum foil you are using.</p>

Send your message to us

Aluminum Foil Facing Rock Wool Board for Wall Partition Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 700 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords