Aluminum Foil Facing Double Sided Paper Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Aluminum Foil Facing-DFR

Aluminum Foil Facing is a kind of film, which is made of by Aluminum foil: 7u / Tri-way fiberglass scrim: 8x12/100mm / Flame retardant adhesive /Kraft paper: 50gsm / Flame retardant adhesive / Aluminum foil: 7u

Application of Aluminum Foil Facing

Our aluminum foil facing are mainly used as facing for glass wool insulation, rockwool, mineral wool etc. Also aluminum foil facing is used under roof decking, under attic rafters, over existing attic thermal insulation, in floors, walls and crawl spaces, and in industrial and commercial buildings to block radiant heat coming into house through the roof during the summer and retain indoor heat generated during in winter

Advantage of Aluminum Foil Facing

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Packing of Aluminum Foil Facing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

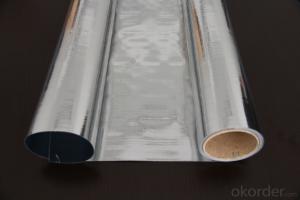

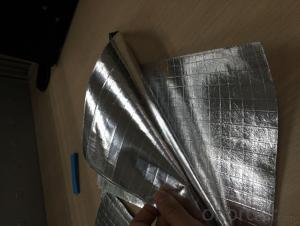

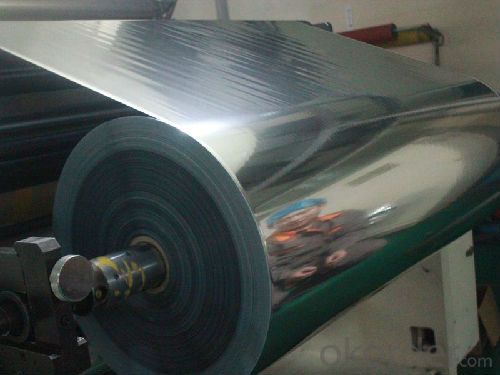

Pictures of Aluminum Foil Facing

Specification of Aluminum Foil Facing

PROPERTIES | UNIT | VALUE | TEST METHOD | |||||

Basic weight | gsm | 110 | ASTM D646 | |||||

Tensile strength: M. D. X. D. | N/25mm | 100 75 | ASTM C1136 | |||||

Burst strength | N | 35 | ASTM D774 | |||||

Reflectivity of foil surface | % | 95 | ---------- | |||||

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of Aluminum Foil Facing and is one of the large-scale professional investment Aluminum Foil Facing bases in China. Annually more than 1000 containers of Aluminum Foil Facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it possible to use aluminum foil facing as a material for baking goods?

- <p>Yes, aluminum foil facing can be used to make baked goods, but it's important to use it correctly. Aluminum foil is a common material used in baking for lining baking sheets and pans to prevent sticking and to facilitate easy removal of baked goods. It's crucial to ensure that the foil is food-grade and safe for use with food. When using aluminum foil, make sure it covers the bottom and sides of the pan to prevent direct contact between the food and the pan, which can lead to uneven cooking or burning. Additionally, avoid using aluminum foil in broilers or at very high temperatures as it may melt or create a fire hazard.</p>

- Q: What are the methods to prevent aluminum foil from shedding into food during cooking?

- <p>To avoid metal flakes from aluminum foil getting into your food, first ensure you're using heavy-duty aluminum foil, which is less likely to tear. Avoid using foil for acidic or highly acidic foods as they can cause the foil to break down. When handling foil, use utensils instead of your hands to prevent oils and salts from your skin causing the foil to flake. Also, do not use foil in broiling or high-heat situations as it can cause the foil to break down and release flakes. Finally, consider using parchment paper or silicone baking mats as alternatives to aluminum foil for certain recipes.</p>

- Q: Is it possible to reuse aluminum foil facing after cleaning it?

- <p>Yes, you can reuse aluminum foil facing after washing it, provided it is thoroughly cleaned and dried. Ensure that all residue is removed and it is completely dry to prevent bacterial growth. However, it's important to note that the foil's effectiveness as a barrier may decrease with each use, and it's generally recommended to use a fresh piece for food safety and hygiene, especially when in contact with food.</p>

- Q: This question asks for clarification on the distinction between two types of aluminum products: aluminum foil facing and aluminum foil sheet.

- <p>Aluminum foil facing is a thin layer of aluminum laminated to a substrate, typically used in construction for insulation and moisture barrier purposes. It provides a reflective surface that can enhance energy efficiency by reflecting heat. On the other hand, aluminum foil sheet is a flat, flexible material made of pure aluminum or aluminum alloy, commonly used in cooking, food packaging, and crafts. It is not bonded to any other material and is available in various thicknesses and widths. The primary difference lies in their applications and composition; foil facing is part of a composite material for construction, while foil sheets are standalone materials for a variety of uses.</p>

- Q: This question is asking for instructions on how to clean and store aluminum foil rolling film to maintain its quality and usability.

- <p>To clean aluminum foil rolling film, gently wipe it with a damp cloth to remove any residue. Avoid using abrasive materials that could scratch the surface. After cleaning, let it dry completely. To store, roll the film tightly and wrap it in a protective layer, such as a plastic wrap or a clean cloth, to prevent dust and scratches. Store it in a cool, dry place away from direct sunlight to maintain its integrity.</p>

- Q: What are the various uses of aluminum foil facing across different sectors?

- <p>Aluminum foil facing is widely used across various industries due to its properties such as heat resistance, moisture barrier, and durability. In construction, it's used for insulation and moisture protection in walls and roofs. In the food industry, it's essential for packaging to preserve freshness and extend shelf life. In the automotive sector, it's used for heat shielding and soundproofing. Additionally, it's utilized in aerospace for lightweighting and heat protection, and in pharmaceuticals for blister packaging. Its versatility makes it indispensable in many manufacturing processes and product applications.</p>

- Q: What are the primary applications or purposes of aluminum foil facing in various industries or everyday life?

- <p>Aluminum foil facing is primarily used for its heat reflective properties, making it ideal for insulation in construction and roofing. It also serves as a moisture barrier and vapor barrier in walls and ceilings, helping to prevent mold and mildew. In the HVAC industry, it's used for duct insulation, enhancing energy efficiency. Additionally, it's utilized in packaging for food and pharmaceuticals to protect contents from light, air, and moisture, thus preserving freshness and quality.</p>

- Q: This question asks for the method of wrapping food using aluminum foil.

- <p>To wrap food with aluminum foil, first clean your hands and ensure the foil is shiny side out. Cut a piece of foil large enough to cover the food completely. Place the food in the center of the foil. Bring the edges of the foil together over the food, then fold and crimp the edges to seal tightly. Ensure there are no gaps to prevent the food from drying out or the foil from tearing. For more complex shapes, you can double the foil and create a pouch or tent, folding the edges to secure the shape. Always handle food with clean hands to maintain hygiene.</p>

- Q: This question asks if there are any potential issues or risks associated with storing food in plastic containers for extended periods.

- <p>Yes, there are concerns about using plastic containers for long-term food storage. Certain plastics can leach chemicals, such as BPA (Bisphenol A) and phthalates, which may be harmful when ingested over time. These chemicals can migrate into the food, especially with exposure to heat or over extended periods. Additionally, plastic containers can break down over time, potentially releasing harmful substances into the food. It's recommended to use food-grade, BPA-free plastics or alternatives like glass containers for long-term storage to minimize health risks.</p>

- Q: What are the potential hazards or dangers of using aluminum foil facing in construction or other applications?

- <p>Using aluminum foil facing can pose certain risks, particularly in construction. It may not provide adequate insulation, leading to energy inefficiency. Additionally, it can trap moisture, causing mold or mildew growth and potential structural damage. Aluminum foil facing can also be a fire hazard if it's not properly installed or if it comes into contact with electrical wiring. Moreover, it may not be as durable as other materials, leading to a shorter lifespan and the need for more frequent replacements. It's crucial to consider these factors and consult with professionals when deciding to use aluminum foil facing in any application.</p>

Send your message to us

Aluminum Foil Facing Double Sided Paper Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords