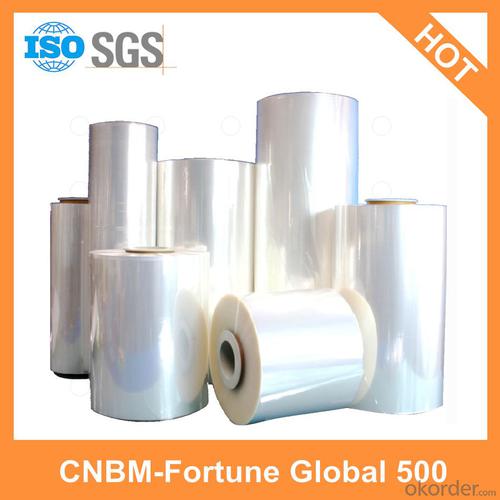

Protective Film Low MOQ Custom Made Model GXH096

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1999 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Protective Film Low MOQ Custom Made Model GXH096

1. Description

Protective Film Low MOQ Custom Made Model GXH096 is a highly stretchable plastic film that is wrapped around items. The elastic recovery keeps the items tightly bound. In contrast, shrink wrap is applied loosely around an item and shrinks tightly with heat.

2. Specification

1. Dimension : Height 50cm x 2.4kg

Core 400g, Nett Film 2kg (A lot of supplier selling the core is heavy buy film is less, please pay attention to it).

2. Quantity : 6 rolls in a carton

3. Advantages

1 ) Different temperature resistance with good adhesion.

2 ) High tensile strength, good resistance of damage,no residue, eco-friendly.

3 ) Printing logo on paper core and carton mark as customers' need

4 ) SGS, ISO,BV, CTI certificates approved

5)Professional teamwork for orders

6)No.365 on the 2012 Fortune Global 500

7) Professional manufacturer with 31 years experiences of adhesive tapes

Special size,color can be made according to customer's requirement

4. Details

Material | PE Film |

Used | Widely Used for protective |

Printing | Offer |

Color | Red, milky, green, white , yellowish, blue, black, or at will. |

Packaging | 6rolls/shrink,12rolls/shrink,72rolls/ctn,144rolls/ctn. |

MOQ | 20ft container or as you need. |

Payment terms | 30% in advance,70% balance the copy of B/L. |

Delivery time | 15workdays except the affirming date of logo on paper core and carton after receiving the deposit. |

Jumbo rolls size

| 1260mm*1800m, 1260mm*1000m |

Width | 3mm~1260mm normal width:12mm,18mm,24mm,36mm

|

Length | 10m~1800m normal length: 20m,33m,50m,100m |

Port | Guangzhou |

Certifications | ISO.9001.2008. and SGS. |

5. Certification

- Q: Is original iPad coated with a protective film?

- No. There's almost nothing complimentary with original iPad.

- Q: What are the materials used in the production of aluminium protective films? What's the harm to life?

- Adhesion is good, easy to paste, easy to peel. The pressure-sensitive adhesive has good stability and does not cause any adverse effects on the surface of the product to be affixed.

- Q: What is PVC material protective film?

- PVC material protective film, as its name suggests, is PVC protective film.

- Q: How to easily remove the protective film of the new refrigerator?

- 1, from the refrigerator side of the next blow with the hair dryer for a while, gently to the side all the way up, slowly torn, with a small rod, roll up and pull out can be, so that the force evenly, once all pull open2, with a washed clean foam produced by the warm water, take a cloth to wipe the protective film, and then let it stand for a while, then the film off, it is very easy

- Q: What are the compositions of the protective film on aluminum alloy profile?

- Acrylic acid PSA. It can be wiped off by lacquer thinner.

- Q: Will the hardware oil layer be taken off with the protective film while tearing the film down?

- No, it won't. The hardware oil layer is formed from gloss oil during electroplating. It has excellent protective function. It won't be taken off with the film.

- Q: Why does PE film curl when rolling it after coating?

- It may happen if the temperature of equipment is too or glue of high adhesion is applied to fairly thin flim. (The solution is to increase the speed or decrease the temperature.) The adhesion of glue is too high because it's too thick, or the base material is not good, or the stress is too strong when drying the film.(Solution: using the inlet air to press the film from the right side to make it flat and ensure the glue won't fall off.) And if the film you use is composite membrane, when the composite membrane is not composited compeletly, the same problem may occur too. I don't know your coating process, thus all above are the possible reasons that I suppose.

- Q: What are the differences between PE protective film, PET protective film and PVC protective film?

- PE refers to polyethylene. It's commonly used in protective films, featuring low price, softness, excellent ductility and environmental friendliness. Generally speaking, products made from this kind of material must pass the ROHS environmental pollution tests stipulated by European Union. Its disadvantage is poor whether resistance. It's not suitable to be used at temperature more than 60℃. PVC refers to polyvinyl chloride. Its features are good softness and whether resistance. And its disadvantage is non-environmental-friendly. Thus many big international brands rarely use this kind of material. Products made from this kind of material are mainly used for anti-static protection or as the surface of wooden stereo. PET refers to polyester. Its major property is good whether resistance which makes it resistant to high temperature of 100℃ to 150℃, hardness and flatness. And its disadvantage is that it can't be used on angular products.It's mainly used in die cutting.

- Q: What are the functions of pure gum protective film?

- It has excellent high-temperature and low-temperature resistance.

- Q: What's the difference between the original film and the protective film?

- The new film machine in the factory when the film strip is not in the true sense, is only a PE film, the main purpose is to ensure that the mobile phone in the factory to the packaging process of the screen is not easy to paste the razor, so this time the film, the film after storage to lose adhesion, easy tear at on the screen, so you need to buy a professional film at the time of the sale, or to allow merchants to send the film to you, but businesses in order to control the cost, when the mobile phone sales are sent scratch proof film, ordinary general quality, according to statistics, 93% of users lose business sent film in use for a period of time later, because the scratch degree is very poor, so I recommend you to understand the film VDOO, non stick in hand, high speed exhaust; blisters washed 10 thousand times without deterioration; spontaneous combustion environment for 3 years with repeated yellow; More than 1000 times, no bubbles; attached to the glass screen, leaving no residual glue;

Send your message to us

Protective Film Low MOQ Custom Made Model GXH096

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1999 m²

- Supply Capability:

- 60000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords