Aluminum Foil Facing Copper Foil for Shielding Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

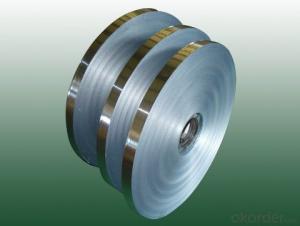

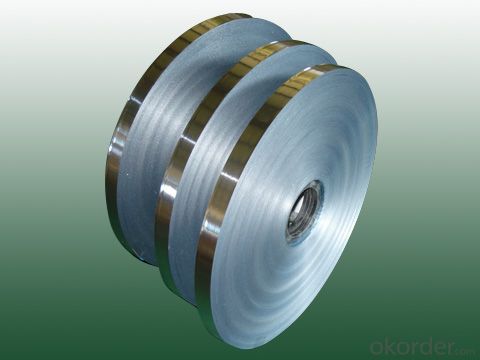

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

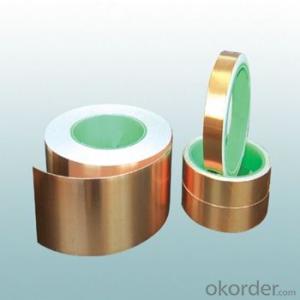

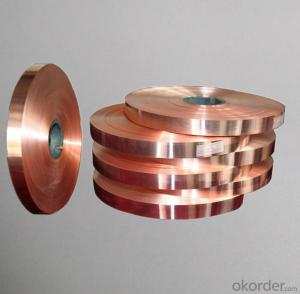

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Is it safe to use aluminum foil facing to wrap food for the purpose of freezing?

- <p>Yes, you can use aluminum foil facing to wrap food for freezing. Aluminum foil is a good conductor of heat and can help food freeze quickly, preserving its freshness. It also protects the food from freezer burn and helps maintain its moisture. However, ensure that the foil is food-grade and avoid using it in direct contact with acidic or high-sodium foods, as these can cause a reaction with the aluminum. For best results, wrap the food tightly and securely to prevent air exposure, which can lead to freezer burn.</p>

- Q: What precautions should be taken when handling hot food using aluminum foil as a cooking tool?

- <p>When handling hot food using aluminum foil, first ensure the foil is thick enough to withstand high temperatures without puncturing. Always use heat-resistant gloves or a thick cloth to avoid burns. Do not wrap food directly in aluminum foil if it's very hot, as this can cause the foil to tear or the food to stick. Allow the food to cool slightly before wrapping. When removing the foil from the heat source, use tongs or a spatula to avoid direct contact with the hot foil. Be cautious of steam when opening the foil, as it can be very hot.</p>

- Q: This question asks for signs or methods to identify if the aluminum foil facing of a product, such as insulation or a jacket, is damaged or defective.

- <p>To determine if your aluminum foil facing is damaged or defective, look for visible signs such as tears, punctures, or holes. Check for any discoloration or rust, which could indicate corrosion. The foil should be smooth and uniform; any irregularities or bubbling might suggest a defect. Additionally, test the integrity by gently pulling or pressing the foil鈥攊f it easily tears or crumples, it may be compromised. For insulation, a damaged foil facing can lead to reduced effectiveness in heat or cold retention, so also consider the performance of the item.</p>

- Q: Explain the distinctions between aluminum foil facing and tin foil, including their composition and uses.

- <p>Aluminum foil facing and tin foil are both thin sheets of metal used for various purposes, but they differ in composition and properties. Aluminum foil facing is a thin layer of aluminum bonded to a substrate, often used in construction for insulation, while tin foil is pure tin and is used for wrapping food or as a decorative element. Aluminum foil is lightweight, corrosion-resistant, and conducts heat well, making it ideal for cooking and insulation. Tin foil, on the other hand, is less common in everyday use due to its higher cost and lower durability compared to aluminum. It is often used in niche applications such as art and craft projects or for certain types of food packaging that require a barrier to light and oxygen.</p>

- Q: Is it safe or practical to use aluminum foil facing as a material for making soup?

- <p>No, it is not advisable to use aluminum foil facing for making soup. Aluminum foil is not designed for direct contact with food, especially when heated, as it can potentially leach aluminum into the food. Additionally, aluminum foil is not a suitable material for cooking vessels as it can tear or puncture easily, leading to safety hazards. Instead, use materials specifically designed for cooking, such as stainless steel, ceramic, or glass cookware, which are safe and non-reactive with food.</p>

- Q: The user is inquiring whether it is safe and practical to use plastic containers for the purpose of freezing food.

- <p>Yes, you can use plastic containers for freezing food, but it's important to choose the right type. Opt for containers labeled as microwave-safe, freezer-safe, or BPA-free. Avoid using containers that become brittle or warp at low temperatures as they may crack or leak. Always leave a little space in the container for expansion to prevent breakage. It's also recommended to transfer frozen food to airtight containers or glass for longer-term storage to maintain food quality and safety.</p>

- Q: Is it safe to use aluminum foil facing inside a pressure cooker and does it pose any risks?

- <p>Using aluminum foil facing in a pressure cooker is generally safe and is commonly used to prevent food from sticking to the pot. However, it's important to ensure that the foil does not block the pressure release valve or the vent, as this could lead to a buildup of pressure and potentially cause the cooker to malfunction. Always follow the manufacturer's guidelines for your specific pressure cooker model to avoid any safety issues.</p>

- Q: How can aluminum foil be organized in a kitchen drawer for easy access and to prevent it from crumpling?

- <p>The best way to store aluminum foil in a kitchen drawer is to use a foil storage box or a cardboard core. Cut off the cardboard tube from a roll of paper towels and place it inside the aluminum foil box. Unroll the foil and wind it around the cardboard tube, ensuring the shiny side is out. This prevents crumpling and makes it easy to tear off the desired amount. Alternatively, you can use a small plastic container with a tight-fitting lid to store the foil neatly and prevent it from unraveling.</p>

- Q: The user is asking if aluminum foil can be used to make a pizza crust more flaky and tender.

- <p>Using aluminum foil facing on a pizza crust won't inherently make it more flaky or tender. The flakiness and tenderness of a pizza crust are determined by the ingredients used and the method of preparation. For a flakier crust, consider using a higher fat content like butter or shortening, and for tenderness, ensure proper hydration and kneading of the dough. Aluminum foil is typically used for its heat distribution properties and to prevent direct contact with the oven rack, which can help in browning the bottom of the crust. However, it doesn't affect the flakiness or tenderness directly.</p>

- Q: Does using aluminum foil facing have any positive effects on health when baking bread?

- <p>Using aluminum foil facing when baking bread does not directly provide health benefits. However, it can help in achieving a more even bake and a better crust, which may enhance the overall quality of the bread. Aluminum foil facing can also prevent bread from burning by reflecting heat away from the bread's surface. While this doesn't impact health, it can improve the bread's taste and texture, which might indirectly contribute to a more enjoyable eating experience and potentially encourage healthier food choices.</p>

Send your message to us

Aluminum Foil Facing Copper Foil for Shielding Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords