Aluminum Composite Panel 6xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

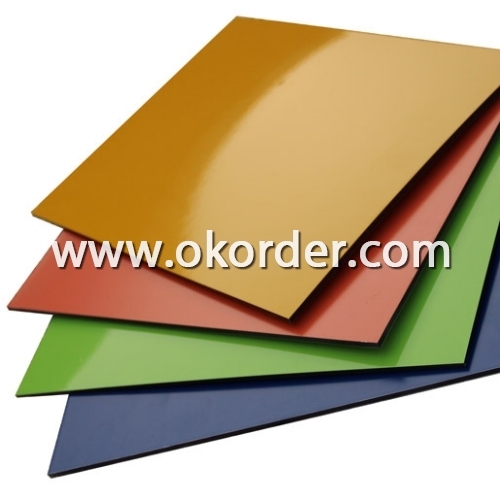

Specifications of Aluminium Composite Panel 6xxx

1.Coating: PVDF/PE

2.Core: unbreakable/ breakable LDPE core

3.ISO9001:2000 and SGS certificate

1. Standard:

according to GB/T 17748-1999 standard

2. Material:

a) Front: aluminum alloy sheet coated with fluoro-carbon resin

(PVDF) and polyester resin (PE) roasting painting

b) Core: nontoxic polyethylene.

c) Back: aluminum alloy sheet coated with polyester resin painting

d) Surface finish: treated with PVDF and PE resin rolling roasting .

coating

e) Surface coating thickness: 30um

f ) Aluminum alloy sheet thickness: 0.1mm, 0.12mm, 0.15mm, 0.2mm,

0.3mm, 0.4mm, 0.45mm, 0.5mm

3. Dimensions:

a) Thickness: 3mm, 4mm

b) Width: 1220mm 1500mm..

c) Length: 2440mm, 3200mm, 4000mm,5000mm (max: 6 meter)

d) Weight: 5.5kg/sqm based on 4mm thickness.

e) Standard size: 1220 x 2440mm

f) Nonstandard sizes are available according to requirement of customers

4. Application scope of aluminium composite panel 6xxx:

1) Building exterior curtain walls..

2) Decoration and renovation additions for old buildings

3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

4) Shop door decorations

5) Advertisement board display platforms and signboards

6) Wallboards and ceilings for tunnels..

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 40 days after getting the buyer's payment.

Repeat rolling - Cleaning - Pretreatment – Coating - Inspection - Film production - Plastic extruding – Compositing - Packing

- Q: This question asks about the energy consumption involved in the manufacturing process of an aluminum can.

- <p>The energy required to process and produce an aluminum can varies based on factors like production scale and technology used. On average, it takes about 70-90 kilowatt-hours (kWh) of energy to produce a single aluminum can. This includes the energy for mining bauxite, refining it into alumina, smelting it into aluminum, and finally, manufacturing the can. The energy consumption is significantly lower compared to producing cans from other materials like steel or plastic, which makes aluminum cans more energy-efficient.</p>

- Q: What are the sustainable methods that can be employed in the manufacturing process involving aluminum?

- <p>Yes, sustainable methods can be employed in aluminum manufacturing. These include using recycled aluminum, which requires significantly less energy than mining and refining new aluminum. Implementing energy-efficient technologies and reducing emissions in the production process are also crucial. Additionally, investing in research for new, more sustainable aluminum alloys and manufacturing processes can lead to reduced environmental impact. Lastly, proper waste management and recycling programs can help minimize the environmental footprint of aluminum production.</p>

- Q: This question asks for methods to protect aluminum from corrosion.

- <p>Aluminum corrosion can be prevented through several methods. One common approach is anodizing, which involves applying a protective oxide layer to the aluminum surface. This process enhances the metal's resistance to corrosion. Another method is using protective coatings such as paints or enamels that act as a barrier against corrosive elements. Cathodic protection, where aluminum is connected to a more easily corroded metal, can also be used. Additionally, ensuring proper design and avoiding contact with aggressive chemicals can minimize corrosion. Regular maintenance and inspection can help detect and address corrosion issues early.</p>

- Q: This question asks about the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in construction due to its lightweight, high strength, and corrosion resistance. It is commonly used in window frames, door frames, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum is also utilized in structural components such as beams and columns, as well as in the manufacturing of prefabricated buildings. Additionally, it is used in the electrical wiring and conduits within buildings due to its excellent conductivity. Its versatility makes it a popular choice for both residential and commercial construction projects.</p>

- Q: Describe the process of electrolysis used in aluminum production.

- <p>The process of electrolysis for aluminum production involves the Hall-H茅roult process, which is the primary method for extracting aluminum from its ore, bauxite. First, bauxite is refined to produce aluminum oxide (alumina). This alumina is then dissolved in a molten cryolite bath, which lowers the melting point and increases the electrical conductivity. Large amounts of electricity are passed through the bath, causing the alumina to decompose into aluminum metal and oxygen gas. The aluminum collects at the bottom of the cell and is periodically tapped off, while the oxygen is released into the atmosphere. This energy-intensive process is crucial for the aluminum industry, as it allows for the production of large quantities of aluminum, a key material in various industries.</p>

- Q: This question asks for an explanation of the environmental effects caused by the process of smelting aluminum.

- <p>The environmental impact of smelting aluminum is significant. It is an energy-intensive process that contributes to greenhouse gas emissions, primarily due to the high electricity consumption required for the Hall-H茅roult process. This process also generates perfluorocarbons (PFCs), which are potent greenhouse gases. Additionally, the production of aluminum releases particulate matter and sulfur dioxide, contributing to air pollution. The extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. Moreover, the waste products, such as red mud, can cause water pollution if not properly managed. Overall, the smelting of aluminum has considerable environmental implications, necessitating the development of more sustainable practices in the industry.</p>

- Q: What are some important safety measures to take when handling or working with aluminum?

- <p>When working with aluminum, it's crucial to take several safety precautions. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and a dust mask to prevent inhalation of aluminum dust. Ensure good ventilation to avoid build-up of fumes, especially during welding or cutting processes. Use proper tools designed for aluminum to prevent sparks and overheating. Be aware of the fire hazard; aluminum can burn at high temperatures, so have fire extinguishers readily available. Finally, be cautious with chemicals used in aluminum processing, as they can be harmful; always follow the manufacturer's safety instructions.</p>

- Q: Is it possible to utilize aluminum in the manufacturing of tools and equipment?

- <p>Yes, aluminum can be used to make tools and equipment. It is valued for its lightweight, corrosion resistance, and high strength-to-weight ratio. Aluminum is commonly used in various applications such as aircraft manufacturing, automotive parts, and consumer electronics. It is also used in the construction of certain types of tools, particularly those that require lightness and durability without the need for extreme strength. However, for applications requiring high strength or resistance to high temperatures, other materials might be more suitable.</p>

- Q: Is it possible to develop allergies from exposure to aluminum found in food packaging materials?

- <p>While aluminum is commonly used in food packaging materials, the risk of allergic reactions to aluminum is generally low for most people. Aluminum is not a known allergen, and exposure through packaging is typically minimal. However, individuals with a rare condition called contact dermatitis may experience skin irritation from aluminum. For the general population, the risk of allergic reactions due to aluminum in food packaging is negligible. It's always important to monitor any unusual reactions and consult a healthcare professional if concerned.</p>

- Q: Is aluminum a suitable material for use in electronic components or devices?

- <p>Yes, aluminum is used in electronics, primarily for its excellent thermal conductivity and electrical conductivity. It is commonly used in heat sinks to dissipate heat from electronic components, such as CPUs and power transistors. Additionally, aluminum is utilized in capacitors and as a conductor in wiring due to its low electrical resistance. However, it is not used as widely as copper for electrical conductivity applications due to copper's superior properties.</p>

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Composite Panel 6xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords