Aluminum Coil Sheet - Color Coated Polyester for Windows

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

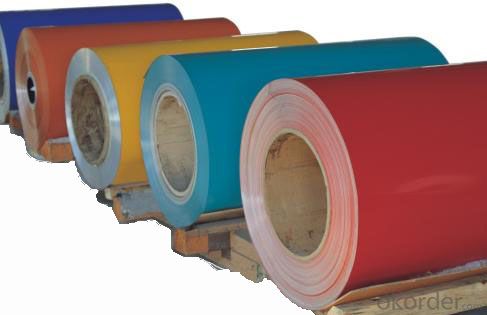

1.Structure of Aluminium Color Coated for Windows Description

PE Coated aluminium coils are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

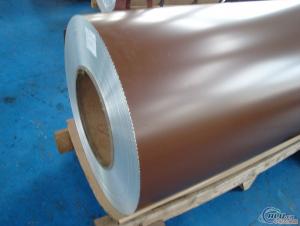

3. Image

4. Products Specification

| Alloy | Paints | Coating Thickness | Period | Final Usage |

| AA3003 | PE | 22-25 MICRONS | 10-15 YEARS | WINDOWS |

5.FAQ

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What are the standard tolerance levels for aluminum coils?

- The standard tolerance levels for aluminum coils can vary depending on the specific industry and application. However, in general, the tolerance levels for aluminum coils are determined by industry standards and specifications such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization). For thickness, the standard tolerance levels for aluminum coils can range from +/- 0.002 inches to +/- 0.020 inches, depending on the specific grade and thickness of the aluminum. Similarly, for width, the tolerance levels can vary from +/- 0.010 inches to +/- 0.250 inches. In terms of flatness, the standard tolerance levels for aluminum coils are typically specified as a maximum deviation from a flat plane. This can range from as low as 0.001 inches to as high as 0.020 inches, depending on the specific requirements of the application. Other factors that may influence tolerance levels include the surface finish, edge condition, and mechanical properties of the aluminum coils. It is important to consult the relevant industry standards and specifications, as well as the specific requirements of the application, to determine the appropriate tolerance levels for aluminum coils.

- Q: How to calculate the dosage of paint for aluminum coil coating? If the weight is 1 ton, the density 2.71 and the thickness 0.12mm, how much paint is needed?

- Coating surface area S*0.12(thickness)*ρ(density) / solid(paint solid)=actual paint consumption brush and roller paint: 100% spray paint: calculated value*70%

- Q: Why do the layers loose when taking out coil after roll of aluminum 0.14?

- After rolling, the most possible reason may be poor deoiling effect. I think, for 0.14mm aluminum coil, the lining sleeve will not be forgotten. After rolling , oil ooze from aluminum layers, and the support of aluminum coil is not enough, leading to coil collapsing. The specific manifestations are that the edges of even round aluminum layers become like water ripple, and that the aluminum coils suddenly become uneven when taking out coil.

- Q: Describe the various uses of aluminum coils in the manufacturing industry.

- <p>Aluminum coils are widely used in manufacturing due to their lightweight, corrosion resistance, and strength. They are utilized in the production of various products such as automotive parts, aerospace components, and construction materials. Aluminum coils are also employed in the manufacturing of electrical wiring, heat exchangers, and packaging materials. Additionally, they are used in the production of cans and foils for food and beverage industries. Their versatility makes aluminum coils an essential material in many manufacturing processes.</p>

- Q: Is there any legislation or regulation governing the use of aluminum coils within specific industrial sectors?

- <p>Yes, there are regulations on using aluminum coils in certain industries. These regulations often vary by country and industry. For instance, in the food and beverage industry, aluminum coils may be subject to food safety standards to ensure they do not contaminate products. In construction, they might need to meet building codes and specifications for strength and durability. The aerospace industry has stringent regulations regarding the materials used in aircraft parts, including aluminum coils. Compliance with these regulations is crucial to ensure safety, quality, and to avoid legal penalties.</p>

- Q: Can aluminum coils be used for electrical connectors?

- Yes, aluminum coils can be used for electrical connectors. Aluminum is a commonly used material for electrical connectors due to its excellent electrical conductivity, relatively low cost, and lightweight properties. It is widely used in various electrical applications, including power transmission and distribution systems, electrical motors, and transformers. However, it is important to ensure proper insulation and protection of the aluminum coils to prevent corrosion and ensure long-term reliability of the electrical connections.

- Q: Are aluminum coils suitable for thermal insulation?

- No, aluminum coils are not suitable for thermal insulation. Aluminum is a highly conductive material, meaning it readily transfers heat. This makes it ineffective in preventing heat transfer between different areas or maintaining a desired temperature within a space. For thermal insulation purposes, materials with low thermal conductivity, such as fiberglass, mineral wool, or foam insulation, are preferred as they minimize heat transfer and provide better insulation.

- Q: What type of equipment is used to process aluminum coils?

- The equipment employed for aluminum coil processing varies depending on the specific manufacturing process and requirements. Nevertheless, there are several common types of equipment used in this process: 1. Uncoilers/Decoilers: These machines are utilized to unroll and straighten the aluminum coils, facilitating further processing. 2. Levelers: Leveling machines are employed to flatten the surface of the aluminum coil, ensuring it is even and flat before proceeding with additional processing. 3. Slitters: Slitting machines are used to cut the aluminum coil into narrower strips of desired widths. This equipment finds frequent use in industries such as automotive, construction, and packaging. 4. Shears: Shearing machines are employed to cut the aluminum coil into specific lengths or shapes required for the manufacturing process. 5. Roll Forming Equipment: Roll forming machines shape the aluminum coil into specific profiles or designs. Commonly employed in the construction industry, they are used to manufacture roofing panels, gutters, and siding. 6. Heat Treatment Furnaces: Heat treatment furnaces subject the aluminum coil to specific temperature conditions to enhance its strength, hardness, or other desired properties. 7. Surface Treatment Equipment: Various equipment, including cleaning machines, chemical baths, and coating lines, are used for surface treatment processes such as cleaning, anodizing, or painting the aluminum coil. These processes improve the coil's appearance, corrosion resistance, or other functional properties. 8. Packaging Equipment: Packaging machines are employed to bundle, wrap, or pack the processed aluminum coils for storage, transportation, or further distribution. It is crucial to note that the specific equipment used may vary depending on factors such as size, thickness, alloy, and intended use of the aluminum coils. Manufacturers often utilize customized equipment to meet their specific requirements and ensure efficient processing.

- Q: Is it possible to use aluminum coils in the creation of toys or games for children?

- <p>Yes, aluminum coils can be used to make toys or games for children, but safety considerations must be taken into account. Aluminum is a lightweight, durable, and non-toxic material, making it suitable for various applications, including children's toys. However, it's crucial to ensure that any aluminum used in toys is properly treated to prevent sharp edges or small parts that could pose a choking hazard. Additionally, the toys or games should be designed and manufactured to meet safety standards and regulations to protect children from potential harm.</p>

- Q: What are the typical dimensions for aluminum coils?

- <p>The standard size of aluminum coils can vary depending on the specific application and industry requirements. Commonly, aluminum coils are available in widths ranging from 600mm to 2000mm and thicknesses from 0.2mm to 6.0mm. The length of the coils can be from 500 meters to over 3000 meters, depending on the weight and the manufacturing process. It's important to note that these dimensions are not fixed and can be customized to meet specific project needs.</p>

Send your message to us

Aluminum Coil Sheet - Color Coated Polyester for Windows

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords