Aluminum Coil Saufit for ACP Based Coil 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Coil for ACP based Coil 1XXX 3XXX 5XXX

1.Structure of Aluminum Coil for ACP based Coil 1XXX 3XXX 5XXX

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Coil for ACP based Coil 1XXX 3XXX 5XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

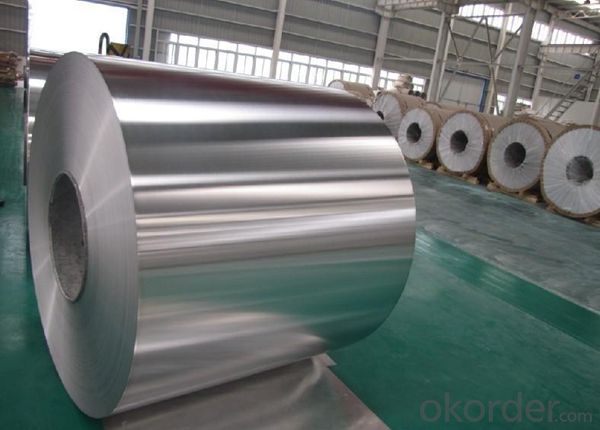

3. Aluminum Coil for ACP based Coil 1XXX 3XXX 5XXX Images

4.Specification of Aluminum Coil for ACP based Coil 1XXX 3XXX 5XXX

Alloy Number | AA5XXX 1XXX 3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Aluminum Coil for ACP based Coil 1XXX 3XXX 5XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: How are aluminum coils coated for color matching and aesthetic purposes?

- The process of coil coating is commonly used to coat aluminum coils for color matching and aesthetic purposes. It is a continuous and highly automated process where a layer of paint or coating is applied onto the surface of the aluminum coil. To start the coil coating process, the aluminum coil is thoroughly cleaned to remove dirt, grease, and oxidation. This is done using chemical cleaning agents and mechanical scrubbing methods to ensure a clean and smooth surface. Once the cleaning process is complete, a primer is applied to the aluminum coil. The primer acts as a bonding agent, improving the adhesion of the subsequent layers of paint or coating. It also helps to prevent corrosion on the aluminum surface. After the primer is applied, the aluminum coil undergoes a series of rollers where the desired color coating is applied. This can be done through various methods such as coil coating, spray coating, or powder coating. Coil coating is the most common method, involving the application of a liquid paint or coating onto the metal coil surface. The coating is then cured or dried using heat to ensure proper adhesion and durability. In order to achieve color matching and aesthetic purposes, the paint or coating used is often customized to specific color palettes or customer requirements. This customization is achieved by using a wide range of pigments and additives that alter the color, texture, and gloss level of the coating. Furthermore, specialized coatings can be applied to aluminum coils to enhance their aesthetic properties. For example, there are coatings available that give the appearance of natural wood or stone, providing a more visually appealing finish. Overall, the process of coating aluminum coils for color matching and aesthetic purposes involves thorough cleaning, priming, and the application of customized paint or coatings. This ensures that the aluminum coils meet the desired aesthetics while also providing durability and protection against corrosion.

- Q: Is there a system or initiative in place for recycling aluminum coils?

- <p>Yes, there are recycling programs for aluminum coils. Many recycling centers accept aluminum coils, and some manufacturers have their own recycling programs. Aluminum is highly recyclable, and recycling it saves energy and resources. To recycle aluminum coils, you can contact local recycling facilities or check with the manufacturer for specific programs. Some regions also have e-waste recycling programs that may accept aluminum coils from electronic devices. It's important to clean and prepare the coils for recycling to maximize their value and recyclability.</p>

- Q: Aluminum metal is oxidized in aqueous base with water serving as the oxidizing agent. Al(s) + H2O(1) → Al(OH)4- + H2(g) (basic solution) Write a balanced equation for this reaction in basic solution.

- You need to add OH- ions on the left. 2Al + 2OH- + 6H2O ---- 2Al(OH4)- + 3H2

- Q: What are the thickness tolerances for aluminum coils?

- The specific grade and alloy of aluminum being utilized can cause variations in the thickness tolerances of aluminum coils. Typically, the range for tolerances in coil thickness is between +/- 0.003 and 0.015 inches (0.076 to 0.381 mm). Nevertheless, it is crucial to acknowledge that various industries and applications might possess their own distinct requirements and tolerances. To ascertain the precise thickness tolerances necessary for a particular application, it is advisable to refer to the appropriate industry standards or specifications.

- Q: I need to draw dot and cross diagrams to explain how they bond, but if the aluminium outer shell has 13 electrons and the oxygen one has 6, how do they all become happy atoms, and all have a full outer shell? please help! thank you.

- I really do not know so ask somebody else

- Q: Can aluminum coils be used in the production of aluminum ceilings?

- Aluminum coils possess the ability to be utilized in the creation of aluminum ceilings. These coils are frequently employed in the fabrication of diverse aluminum goods, which encompass aluminum ceilings. Typically, these coils are crafted from top-notch aluminum alloy, which is then processed and molded into coils with the desired dimensions in terms of thickness and width. The coils can be effortlessly cut and molded into the necessary dimensions for the ceiling panels. Furthermore, aluminum is a lightweight, robust, and corrosion-resistant substance, rendering it an optimal choice for ceilings. It is also highly adaptable, allowing for a multitude of finishes and designs to be employed on the aluminum surface, which further amplifies the aesthetic allure of aluminum ceilings. On the whole, aluminum coils play a pivotal role in the production of aluminum ceilings by offering a dependable and enduring material for such applications.

- Q: What are the different types of alloys used for aluminum coils?

- Aluminum coils are commonly made using several different types of alloys. The most frequently used alloy for aluminum coils is 3003, which is known for its excellent corrosion resistance and moderate strength. It finds its application in roofing and siding where high strength is not a requirement. 5052 is another alloy that is commonly used for aluminum coils. This alloy possesses good weldability and formability, making it suitable for a wide range of uses. In the automotive industry, it is often employed for body panels and fuel tanks. 6061 is a popular choice for aluminum coils due to its outstanding strength. It is frequently used in structural applications, such as aircraft parts in the aerospace industry and structural components in the construction industry. Additionally, other alloys like 1100, 5005, and 8011 are also used for aluminum coils. Each of these alloys has distinct properties and characteristics that make them suitable for different applications. For instance, 1100 is known for its high electrical conductivity and is commonly used in electrical applications. On the other hand, 8011 is frequently utilized for packaging and food containers due to its excellent corrosion resistance. In conclusion, the various alloys used for aluminum coils include 3003, 5052, 6061, 1100, 5005, and 8011. These alloys possess different properties and characteristics, making them suitable for a wide range of applications across industries like automotive, aerospace, construction, and packaging.

- Q: What are the common surface finishes for aluminum coils in the electrical industry?

- The common surface finishes for aluminum coils in the electrical industry include mill finish, anodized finish, and painted finish.

- Q: I want to know when it comes to racing which is better? I have a 24 inch aluminium bmx frame and want to know if chromoly frames are faster? Also before buying parts for my bike should I go all aluminum like the bars and forks? Also which is faster the aluminum or the chromoly frame?

- There are no 24 inch BMX frames.

- Q: Can aluminum coils be bent or shaped?

- Indeed, aluminum coils possess the capability of being bent and shaped. Aluminum, as a remarkably malleable and ductile metal, can undergo manipulation and take on diverse forms effortlessly, without experiencing any fractures or cracks. The pliability of aluminum grants it the capacity to be bent, rolled, or molded into coils, solidifying its prominence in a wide array of applications, including the production of air conditioning units, automotive components, and packaging materials. The flexibility and shape-altering potential of aluminum coils render them exceptionally versatile and adaptable to meet specific design specifications, facilitating efficient and precise customization across a multitude of industries.

Send your message to us

Aluminum Coil Saufit for ACP Based Coil 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords