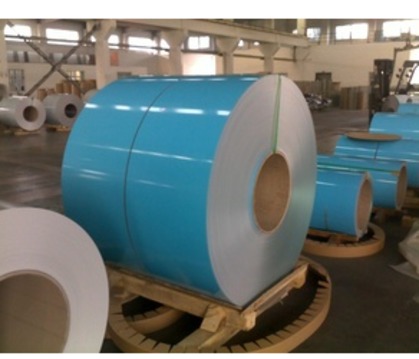

Flat Aluminum in Coils (500-2000kgs Available)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Coil of 500-2000kgs Avaliable for Customer :

Mill Finished Aluminum Coil is designed for many field such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc.. Mill finished aluminum coil for is hard and everlasting under the blazing sun. You can choose the alloys as your habitation and we will do our best to meet your requests.

2.Main Features of the Aluminum Coil of 500-2000kgs Avaliable for Customer:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminum Coil of 500-2000kgs Avaliable for Customer

Alloy: | AA1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006 |

Temper: | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness: | 0.2-100mm |

Width: | 30mm-1700mm |

4. Production of Aluminum Coil of 500-2000kgs Avaliable for Customer

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: How do aluminum coils compare to other types of coils (e.g., copper)?

- Aluminum coils and copper coils are two common types of coils used in various industries. While both have their own advantages and disadvantages, it is important to understand how they compare to each other. One of the main differences between aluminum and copper coils is their conductivity. Copper is known for its excellent electrical and thermal conductivity, making it a preferred choice for applications that require high levels of heat transfer efficiency. Aluminum, on the other hand, has a lower conductivity compared to copper, but it is still a good conductor of electricity and heat. Another key factor to consider is the cost. Copper is more expensive than aluminum, primarily due to its higher demand and limited availability. Therefore, aluminum coils are often chosen as a cost-effective alternative, especially in applications that do not necessarily require the high conductivity of copper. In terms of weight, aluminum coils are significantly lighter than copper coils. This makes them easier to handle and install, reducing overall transportation and labor costs. The lightweight nature of aluminum coils also makes them suitable for applications where weight is a concern, such as in the automotive and aerospace industries. When it comes to corrosion resistance, copper coils have the upper hand. Copper is highly resistant to corrosion, ensuring longer lifespan and less maintenance. Aluminum, on the other hand, is more prone to corrosion, especially in environments with high humidity or exposure to certain chemicals. However, with proper coatings and treatments, aluminum coils can be protected against corrosion effectively. Durability is another aspect to consider. Copper coils are known for their durability and ability to withstand extreme conditions, making them suitable for applications where longevity is crucial. Aluminum coils, while not as durable as copper, can still provide satisfactory performance in many applications, especially when properly designed and maintained. In summary, aluminum coils and copper coils have their own distinct characteristics and advantages. Copper coils offer superior conductivity, corrosion resistance, and durability, but they come at a higher cost. Aluminum coils, on the other hand, are lighter, more cost-effective, and suitable for various applications. Ultimately, the choice between the two types of coils depends on the specific requirements, budget, and environmental factors of the application at hand.

- Q: What are the proper storage methods to maintain the quality of aluminum coil for future use?

- <p>To store aluminum coil for future use, ensure it is kept in a cool, dry place away from direct sunlight and moisture. Stack the coils on flat, level surfaces with appropriate padding to prevent damage. Avoid stacking with other metals to prevent galvanic corrosion. Use clean, dry hands or gloves when handling to prevent oil and dirt from contaminating the surface. Store in a controlled environment with a relative humidity below 65% and a temperature between 32掳F to 90掳F (0掳C to 32掳C). Regularly inspect the coils for any signs of corrosion or damage.</p>

- Q: The user is asking if it's possible to use a punching machine to create holes in aluminum coils.

- <p>Yes, you can use a punching machine to punch holes in aluminum coils. Punching machines are designed to cut or create holes in various materials, including metals like aluminum. However, the type of punching machine and the specific settings will depend on the thickness and hardness of the aluminum coils. For thicker or harder aluminum, a more robust machine with appropriate dies may be necessary. Ensure that the machine is capable of handling the material's properties to avoid damage or inefficiencies in the punching process.</p>

- Q: What is the hardness range of aluminum coils?

- The hardness range of aluminum coils typically falls between 40 and 70 on the Rockwell hardness scale.

- Q: i have received an aluminium cooker,it's in good condition but the outside is discoloured by oil splatters.The body is round ,i have used baking soda+vineger( mix with water and boil for an hour) to clean the insides,it came off clean but outside i have no clue. used a lot of elbow grease,my hands are paining now..i have this thing for gleaming utensils ,any suggestions with homemade things,don't want to buy anything

- To clean discolored aluminum you can also heat 2 teaspoons cream of tarter per quart of water. It would be best to let the cooker soak in the mixture, but that might be difficult depending on the size of your cooker. Lemon juice or lime juice should also help because they have citric acid. You could cut a lemon in half and rub the halves on the cooker, then try scrubbing with something that has some texture to it (rough sponge or steel wool). The try the vinegar or cream of tarter mixture again. Whatever you use, don't try bleach as it is highly alkaline and dissolves aluminum. This leaves copper deposits can make it turn black.

- Q: WHERE IS ALUMINIUM FOUND, LIKE WHERE IS IT MINED FROM...10 points tell me quick

- Aluminum and Iron the two form an oxide coating on the exterior of the organic metallic. Iron oxide and aluminum oxide are very diverse even inspite of the undeniable fact that. Rust is extremely comfortable and wears away today, exposing a clean Iron floor. Aluminum oxide is what a ruby is produced from (alongside with somewhat Chromium for shade). Rubies are basically somewhat softer than diamonds, the toughest substance well-known. The oxide coat on Aluminum is extremely skinny yet in addition very not effortless. It adheres to the exterior and forestalls any greater desirable corrosion. concerning to Chromium, it is the key element in chrome metallic. metallic is an Iron alloy with a small quantity of Nickel, Molybdnium, Vanadium or perhaps Copper and Phosphorus. chrome metallic resists rust so nicely because of the fact the Chromium will form an oxide coating a similar way Aluminum does. because of the fact the Chromium is unquestionably component to the alloy, if the chrome metallic is scratched, the clean floor quickly coats with a protecting layer of Chromium oxide.

- Q: What are the potential applications of mill-finished aluminum coils?

- Mill-finished aluminum coils have a wide range of potential applications due to their versatile properties and finishes. Some of the potential applications of mill-finished aluminum coils include: 1. Building and construction: Mill-finished aluminum coils are commonly used in the building and construction industry for various applications. They can be used for roofing, siding, wall cladding, gutters, and downspouts, among others. The mill finish provides a clean and smooth appearance, enhancing the aesthetic appeal of the building while also offering durability and corrosion resistance. 2. Automotive industry: Mill-finished aluminum coils find applications in the automotive industry due to their lightweight nature, high strength-to-weight ratio, and corrosion resistance. They can be used for manufacturing body panels, trims, and other components, contributing to fuel efficiency and reducing the overall weight of vehicles. 3. Electrical industry: Mill-finished aluminum coils are used in the electrical industry for various applications. They can be used for manufacturing electrical enclosures, transformers, busbars, and conductors due to their electrical conductivity and corrosion resistance. The mill finish ensures a high-quality surface finish for these electrical components. 4. Packaging industry: Mill-finished aluminum coils are widely used in the packaging industry due to their excellent barrier properties and formability. They can be used for manufacturing aluminum foil, cans, lids, and other packaging materials. The mill finish provides a smooth surface, making it suitable for printing and branding purposes. 5. Household appliances: Mill-finished aluminum coils are used in the manufacturing of household appliances such as refrigerators, ovens, and air conditioners. They provide a lightweight and corrosion-resistant solution for these appliances, ensuring durability and energy efficiency. 6. Aerospace industry: Mill-finished aluminum coils find applications in the aerospace industry due to their lightweight nature and high strength. They can be used for manufacturing aircraft structures, interior components, and other parts. The mill finish provides a smooth surface, ensuring aerodynamic efficiency and reducing drag. 7. Marine industry: Mill-finished aluminum coils are widely used in the marine industry for various applications. They can be used for manufacturing boat hulls, decks, and other components due to their corrosion resistance and lightweight properties. The mill finish ensures a clean and polished appearance, enhancing the aesthetics of the vessel. Overall, mill-finished aluminum coils have numerous potential applications across various industries due to their versatile properties, including lightweight, corrosion resistance, formability, and aesthetic appeal.

- Q: Are aluminum coils susceptible to warping or bending?

- Aluminum coils are prone to warping or bending due to their susceptibility. Despite being lightweight and highly resistant to corrosion, aluminum is relatively soft when compared to materials such as steel. Consequently, it is more likely to bend or warp under specific circumstances. Contributing factors include excessive heat, heavy loads, or mishandling, which can result in deformation of the aluminum coils. To avoid any damage or distortion, it is crucial to handle and store the coils with caution. Furthermore, employing appropriate installation techniques and maintenance practices can effectively reduce the risk of warping or bending.

- Q: My boyfriend sweats a lot and uses Mitchlum deodorant, a lot of it, under his armpits and waits til it dries to stop the sweating. I heard aluminium was bad for you, but he says natural deodorants don't work as well. What do you think?

- This is doctrine according to me, so Don't take it for absolute truth. I had a science teacher who said the aluminum in deodorant was bad for you because you have major arteries in your armpits that go to the rest of your body and it carries it there and is linked to things like alzheimers (please excuse my spelling). Then I had another teacher who said that that was complete rubbish. Aluminum is everywhere. If it was going to do that from deodorant, it would do it from a million other things. Oh, and certain deodorants work for certain people, others not so well. I actually have to switch types every once in a while because the one I use stops working. In my experience, the natural stuff doesn't work as well. So, you don't have to believe me, but you asked what I thought.

- Q: Are aluminum coils resistant to saltwater corrosion?

- Yes, aluminum coils are generally resistant to saltwater corrosion. Aluminum is known for its excellent corrosion resistance, especially in marine environments where saltwater exposure is common. The naturally forming oxide layer on the surface of aluminum provides a protective barrier against saltwater corrosion. This oxide layer acts as a shield, preventing direct contact between the aluminum and the corrosive saltwater. Additionally, aluminum coils can be further protected through various coating methods, such as anodizing or painting, which enhance their resistance to saltwater corrosion even further. However, it is important to note that prolonged or continuous exposure to saltwater can gradually degrade the protective oxide layer and may eventually lead to corrosion, although this process is typically slow. Regular maintenance and proper care can help extend the lifespan and performance of aluminum coils in saltwater environments.

Send your message to us

Flat Aluminum in Coils (500-2000kgs Available)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords