Aluminum Coil 0.05 X 102 - PE/PVDF Red Color Wooden Grains Aluminum Coil for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Wooden pattern coated Aluminum coil /anodized aluminum coil 1100/3003 :

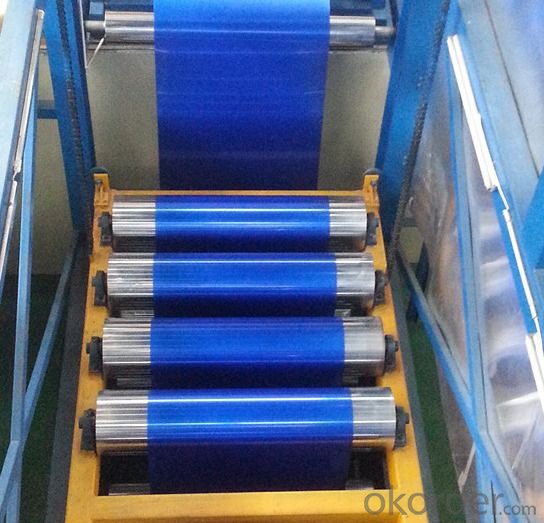

Our PVDF coated color aluminum coil is made of high-performance aluminum sheet and PVDF coating through advanced roller coating process.

Features:

1) Wear resistance 2) impact resistance 3) highly tensile strength 4) easy fabricating 5) UV resistance 6) weather resistance 7) corrosion- resistance 8) various colors

Aluminum foil range:

Thickness: 0.18mm-1.6mm

General Width: 1240mm, 1270mm, 1520mm, 1570mm, other special widths according to customer requirements;

Aluminum alloy: 1100,3003,8011,3105,5052, other alloys according to customer requirements.

Applications:

PVDF coated aluminum coil is a favorably choice of material for high-quality aluminum curtain wall, aluminum veneer sheet, Honeycomb panel. Its products are widely used in airports, convention centers, hotels and other high-end architectural curtain wall decoration

Aluminum Plates:

Aluminum coils / plates are widely used in building renovation (aluminum panels, honeycomb panels, aluminum veneer, tiles, ceiling, doors, windows, etc.), food packaging (such as bottle caps, lids). They can be used as cooling and temperature control material in electrical equipment.

| Aluminium series | Alloy | Temper | Thickness | Width | Pattern | Usage |

| 1000 series | 1050/1060/1070/1100 | H0-H112 | 0.3mm-5.0mm | 300mm-2200mm | Sheet/Coil | Chemical equipment, food industry equipment |

2000 series | 2014/2017/2024 | O,T3,T4 | 100mm-1250mm | Sheet/Coil | General Mechanical Components | |

| 3000 series | 3003/3004/3005/3105 | O/H32/H34/H36/H38/H116 | 0.2mm-6mm | 400mm-2000mm | Sheet/Coil | Building, PP cap material |

| 5000 series | 5005/5052/5083/5086/5182/5754 | O/H32/H34/H36/H38/H116 | 0.12mm-10mm | 20mm-2000mm | Sheet/Coil | Architectural decorative pieces, conductor, cookware |

| 6000 series | 6061/6205/6009/6010 | O/T4/T6 | 0.6mm-5mm | 100mm-1800mm | Sheet/Coil | Industrial structures, ships, trams, furniture components |

| 7000 series | 7038/7050/7075 | O/T6/T76 | 0.1mm-3.0mm | 400mm-2000mm | Sheet/Coil | Refrigerated containers, cryogenic equipment and storage tanks |

Quality Standard:

| Test Item | PE | PVDF | ||||||

| Chromatism(ΔE) | Ceiling Decoration | Engineer Ceiling | Primer Print | Back Print | Ceiling Decoration | Engineer Ceiling | ||

| ≤0.5 | ≤0.7 | ≤0.8 | ≤2.0 | ≤0.5 | ≤0.7 | |||

| Pencil Hardness | ≥HB (No Crack or peel off) | |||||||

| Adhensive Resistance | Grade 0;No crack or peel off after the circling&pasting | Grade 0;No crack or peel off after the circling&pasting | ||||||

| Impact Resistance | ≥0.5mm | 0.3-0.5mm | ≥0.5mm | 0.3-0.5mm | ||||

| 50kgs.cm | 20kgs.cm | 50kgs.cm | 20kgs.cm | |||||

| Boiling Water Resistance | no changes by circling after 2h boiling | no changes by circling after 2h boiling | ||||||

| T-Bend Flexibility | composite panel | Ceiling Decoration | Engineer Ceiling | Primer/Back Print | Composite Panel | Ceiling Curtain | ||

| ≤2T | ≤1T | ≤2T | ≤3T | ≤2T | ≤2T | |||

| Coating Thickness(μm) | Topcoat | Primer coating | Double printing | Back Print | Topcoat | Back Print | total coating thickness | |

| ≥16 | 9~11 | 25~28 | 9~12 | 18-20 | 9~11 | 25-28 | ||

| Solvent Resistent | Single print≥100 times | Double print≥200 times | Back Print:30-70 times | Back Print:30-70 times | ≥200 times | |||

FAQ of PE/PVDF Red Color Wooden Grains Aluminum Coil For Aluminum Composite Panel:

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

- Q: What is the creep resistance of aluminum coils?

- The creep resistance of aluminum coils is generally high, as aluminum has a low melting point and exhibits minimal creep deformation under normal operating conditions.

- Q: What’s the difference between aluminum tile, coil and sheet? Why?

- Wood pallet is often used, which is easy to transport and can ensure the safety of products.

- Q: Are there any restrictions on the coil thickness of aluminum coils?

- Yes, there are typically restrictions on the coil thickness of aluminum coils. The specific restrictions may vary depending on the intended application and industry standards. Generally, the thickness of aluminum coils is limited by the capabilities of the manufacturing equipment and the desired final product. Thinner coils are often preferred for applications that require flexibility, such as in the manufacturing of foils or flexible packaging materials. On the other hand, thicker coils are commonly used in industries like construction or automotive, where strength and durability are important factors. Additionally, the thickness of aluminum coils may be restricted by the availability and cost of raw materials. It is important for manufacturers to adhere to these restrictions to ensure the quality and performance of the final product.

- Q: This question seeks to understand the various types of aluminum coils that are commonly found in the market.

- <p>Aluminum coils available on the market today can be categorized based on their properties and applications. These include: 1. Plain Aluminum Coils: Used for general purposes like packaging and construction. 2. Embossed Aluminum Coils: Feature a textured surface, used in decorative applications. 3. Alloy Aluminum Coils: Made from a mixture of aluminum and other metals for enhanced strength or corrosion resistance. 4. Color Coated Aluminum Coils: Coated with paint or plastic for aesthetic or protective purposes. 5. Heat Treated Aluminum Coils: Processed to improve their mechanical properties. 6. Mirror Finish Aluminum Coils: Have a highly reflective, polished surface. 7. Pre-painted Aluminum Coils: Coated with a layer of paint before being used in construction or other applications. Each type serves specific industries and applications, with variations in thickness, width, and alloy composition.</p>

- Q: How do aluminum coils compare to magnesium coils in terms of strength?

- In comparison to magnesium coils, aluminum coils typically exhibit greater strength. Aluminum is renowned for its exceptional strength-to-weight ratio, thus rendering it a favored option across multiple industries. It boasts a higher tensile strength and superior resistance to deformation when subjected to stress, unlike magnesium. Moreover, aluminum possesses a higher yield strength, enabling it to withstand more substantial loads before succumbing to permanent deformation. Conversely, magnesium, despite its lighter nature, tends to possess inferior strength attributes. Although magnesium coils may prove beneficial in specific scenarios where weight plays a crucial role, aluminum coils are generally favored for their strength and longevity.

- Q: What are the different alloys used for aluminum coils?

- There are several different alloys used for aluminum coils, including 1100, 3003, 5052, and 6061. Each alloy has its own unique properties and characteristics, making them suitable for various applications. For example, 1100 is often used for chemical and food processing equipment, while 3003 is commonly used in heat exchangers and cooking utensils. 5052 is known for its high corrosion resistance and is often used in marine and transportation industries. Lastly, 6061 is a versatile alloy used in structural components, aerospace applications, and automotive parts.

- Q: What are the various applications and purposes for which aluminum coils are utilized?

- <p>Aluminum coils have a wide range of applications due to their lightweight, corrosion resistance, and malleability. They are commonly used in construction for roofing and siding, in the automotive industry for car parts and body panels, in the packaging industry for cans and foils, and in electrical applications for wiring and transformers. Aluminum coils are also used in the manufacturing of heat exchangers, cooking utensils, and various consumer products. Their versatility makes them an essential material in many industries.</p>

- Q: I was going to buy a turkey roaster pan today and an elderly couple stopped me and told me to buy another one that was made of stainless steel instead of aluminum because aluminum does something to your brain. What is the story?Just curious. Does this also ring true for using a sheet of aluminum foil over baking sheets while cooking cookies or fries or something? I always coat my cookie sheets with foil. Just curious...

- For okorder /19

- Q: This question asks for the method to measure the dimensions of an aluminum coil.

- <p>To measure the size of an aluminum coil, you'll need to measure its diameter, width, and thickness. Use a tape measure or a caliper to measure the coil's diameter and width. For the thickness, a micrometer or a coil thickness gauge can be used. Ensure the coil is laid flat and measure at several points to get an average thickness. If the coil is wound, you may need to unroll it partially to take accurate measurements. Always follow the manufacturer's guidelines for your specific measuring tools to ensure accuracy.</p>

- Q: How are aluminum coils protected against moisture during storage?

- Aluminum coils are typically protected against moisture during storage through the use of various methods and materials. One common method is the application of a protective coating, such as a thin layer of oil or a corrosion-resistant film, which forms a barrier between the coil and any moisture present in the environment. This coating helps to prevent direct contact between the aluminum surface and water, minimizing the risk of corrosion or other moisture-related damage. In addition to protective coatings, aluminum coils may also be stored in a controlled environment with low humidity levels. This can be achieved by storing the coils in a dry warehouse or using dehumidifiers to remove excess moisture from the storage area. By controlling the humidity, the risk of moisture condensation on the coils is reduced, further protecting them from potential damage. Furthermore, proper packaging is crucial in protecting aluminum coils against moisture during storage. Coils are often wrapped in moisture-resistant materials, such as plastic or moisture-proof paper, to create a barrier that prevents moisture from reaching the coils. Additionally, the packaging is often sealed to provide an airtight environment, further minimizing the chances of moisture ingress. Regular inspection and maintenance are also important to ensure the continued protection of aluminum coils during storage. This includes checking the integrity of the protective coatings, monitoring the storage environment for any changes in humidity levels, and promptly addressing any signs of moisture damage. Overall, the use of protective coatings, controlled storage environments, proper packaging, and regular maintenance are key factors in protecting aluminum coils against moisture during storage. By implementing these measures, the risk of moisture-related damage is significantly reduced, ensuring the quality and integrity of the coils until they are ready for use.

Send your message to us

Aluminum Coil 0.05 X 102 - PE/PVDF Red Color Wooden Grains Aluminum Coil for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords