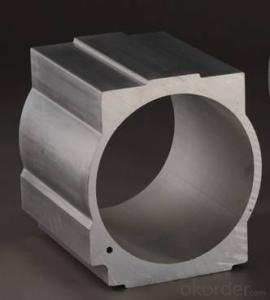

Aluminum Air Cylinder Shell with Aluminum Pipes

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, Mill,rtc |

Colour | Mill |

Length | -- |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Air cylinder shell; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

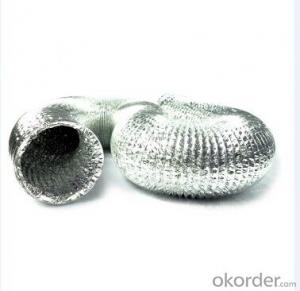

- Q: There's a small hole in the aluminum tube on the air conditioner. Can I use it?

- If is refrigerant tube, a hole is impossible to run, the refrigerant had leaked out.If you want to continue to use air conditioning, must find a professional maintenance staff to pipe trap, re filling refrigerant can.

- Q: Are aluminum pipes suitable for potable water systems?

- Potable water systems can indeed make use of aluminum pipes. Aluminum, being a lightweight and corrosion-resistant material, offers a durable and long-lasting solution for the transportation of potable water. It is widely employed in plumbing systems, catering to both hot and cold water requirements. The high strength-to-weight ratio of aluminum pipes makes them effortlessly installable and transportable. Moreover, aluminum exhibits low reactivity towards water, ensuring that it does not readily release harmful substances into the water supply. Nevertheless, it is crucial to note that to prevent any potential reactions with water, aluminum pipes should be adequately coated or lined. Uncoated aluminum may release small quantities of aluminum ions into the water. All in all, with the appropriate coating or lining, aluminum pipes can serve as a suitable and secure option for potable water systems.

- Q: What ion is corrosive to the aluminum tube?

- Too much, mainly is the strong oxidizing ion such as hydrogen ion, iron ion, nitrate ion, permanganate ion and so on

- Q: What is the chemical composition of aluminum pipes?

- The chemical composition of aluminum pipes is primarily composed of aluminum (Al) as the main element.

- Q: Automatic necking machine for aluminum pipe necking is what causes Hoove

- You can look at the Taizhou Federation of mechanical and electrical automatic CNC necking machine, CNC system to control the circular roller work, as if the effect can also be.If the pilot type relief valve, may be caused by not unloading overflow valve orifice plug through a relief valve.

- Q: What are the disadvantages of using aluminum pipes?

- There are several disadvantages of using aluminum pipes in various applications. Firstly, aluminum pipes have lower strength and durability compared to other materials like steel. This means that they may not be suitable for applications that require high pressure or heavy loads. The lower strength can result in bending or deformation of the pipes, which can compromise their functionality. Secondly, aluminum is more susceptible to corrosion compared to materials like stainless steel. This can be a significant drawback in environments with high humidity, acidic or alkaline conditions, or exposure to certain chemicals. Corrosion can lead to leaks or failures in the pipes, resulting in potential damage to the system or infrastructure. Additionally, aluminum pipes have a higher coefficient of thermal expansion than materials like steel. This means that they are more prone to expand or contract with temperature changes. This can cause issues in applications where precise dimensions or tight fittings are required, as the pipes may not maintain their original shape or size under varying temperatures. Moreover, aluminum pipes are relatively more expensive compared to other materials such as PVC or copper. This can be a disadvantage for projects with budget constraints, as the cost of aluminum pipes can significantly impact the overall expenses. Lastly, aluminum is a good conductor of heat and electricity. While this can be advantageous in certain applications, it can also be a disadvantage in others. For example, in applications involving refrigeration or insulation, aluminum pipes can lead to heat transfer or energy loss, making them less efficient compared to materials with better insulation properties. Overall, the disadvantages of using aluminum pipes include lower strength and durability, susceptibility to corrosion, higher coefficient of thermal expansion, higher cost, and potential heat or energy transfer issues. It is important to carefully consider these drawbacks in relation to the specific requirements of the application before choosing aluminum pipes as the preferred material.

- Q: Are aluminum pipes resistant to saltwater corrosion?

- Yes, aluminum pipes are generally resistant to saltwater corrosion. Aluminum is known for its excellent corrosion resistance, including resistance to saltwater. It forms a thin, transparent oxide layer on its surface when exposed to oxygen, which acts as a protective barrier against corrosion. This oxide layer helps to prevent the metal from reacting with saltwater, thus making aluminum pipes highly resistant to saltwater corrosion. However, it is important to note that prolonged exposure to saltwater can still lead to some degree of corrosion over time, but compared to other metals, aluminum is considered to be one of the most corrosion-resistant materials for saltwater applications.

- Q: Can aluminum pipes be used for gas transportation?

- Yes, aluminum pipes can be used for gas transportation. Aluminum is a lightweight and corrosion-resistant material, making it suitable for safely transporting various gases.

- Q: Why are copper tubes used in household air conditioners and aluminium tubes for automotive air conditioners?

- The air conditioning copper tube is a kind of pressed and drawn seamless pipe. The air conditioner copper tube has the advantages of light weight, good heat conductivity and low temperature intensity. Copper tubes are often used as connecting pipes for air conditioners. Air conditioning aluminum tube is also a kind of non-ferrous metal pipe. The air conditioning aluminum tube is made of pure aluminium or aluminum alloy and is extruded into a hollow metal tube with longitudinal length. Air conditioning aluminum tube has "annealing, quenching and hot state, medium plasticity, good weldability, weldability" and so on. Aluminium tubes are also used for air conditioning. But for the moment, copper tubes are more suitable for air conditioning than aluminum tubes.

- Q: What are the different bending techniques for aluminum pipes?

- There are several bending techniques for aluminum pipes, including rotary draw bending, induction bending, and mandrel bending. Rotary draw bending involves using a die and a mandrel to bend the pipe around a bend die. Induction bending uses heat to soften the aluminum pipe before bending it using a bending machine. Mandrel bending utilizes a mandrel inside the pipe to support it during the bending process, preventing it from collapsing or wrinkling.

Send your message to us

Aluminum Air Cylinder Shell with Aluminum Pipes

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords