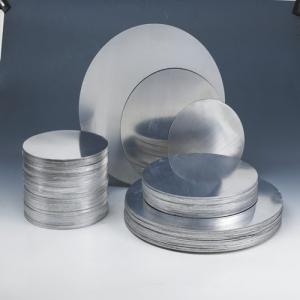

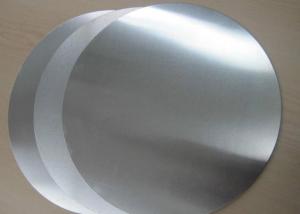

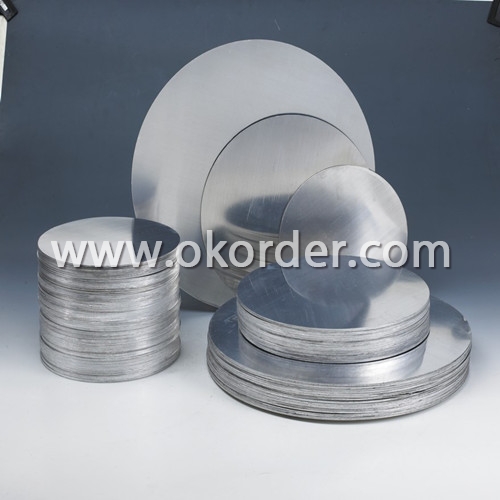

Aluminum AA5xxx Circles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0.5 T

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Circle AA5***

Alloy Number | AA5*** |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.50mm--6.00mm |

Diameter | 100mm--1200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirements.

2. Usage/Applications of Aluminum Circle AA5***

Aluminum Circles have a wide variety of applications in cookware and kitchenware, including fried pans and pressure cooker. C.C. circle is excellent for spinning, deep-drawing (depth less than 10 cm), color or non-sticky painting with quite competitive price.

3. Packaging & Delivery of Aluminum Circle AA5***

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 40 days after getting the buyer's payment.

4. Production Flow of Aluminum Circle AA5***

Melting-Rolling- Cutting- Annealing--Packing

- Q: Is it possible to recycle aluminum within the context of car battery recycling facilities?

- <p>Yes, aluminum can be recycled in a car battery recycling facility. Car batteries contain aluminum components, and recycling facilities are equipped to separate and recycle aluminum from other materials. The process typically involves disassembling the batteries, separating the aluminum casings from the lead acid, and then melting the aluminum for reuse. This not only conserves resources but also reduces the environmental impact of battery waste.</p>

- Q: This question asks for examples of alloys that have a significant amount of aluminum and are known for their strength and ductility.

- <p>Alloys that are known for their high aluminum content and possess excellent strength and ductility include 6061 aluminum alloy, 7075 aluminum alloy, and 2024 aluminum alloy. 6061 is widely used in structural applications due to its balance of strength, corrosion resistance, and formability. 7075 is one of the strongest aluminum alloys and is used in aerospace and high-strength applications. 2024 is known for its good mechanical properties and is used in aircraft structures and other demanding applications. These alloys leverage the benefits of aluminum, such as low density and high resistance to corrosion, while their specific compositions and heat treatments enhance their strength and ductility.</p>

- Q: This question asks for recent applications of aluminum in the transportation industry.

- <p>Aluminum has found new uses in transportation due to its lightweight and high strength properties. It's increasingly used in electric vehicles to reduce weight and extend battery life. Aluminum alloys are also utilized in the construction of high-speed trains and aircraft to improve fuel efficiency and performance. In addition, aluminum is employed in the manufacturing of automotive parts such as engine components, wheels, and body panels. Furthermore, it's used in the production of lightweight bicycles and other transportation infrastructure like bridges and road signs. The trend towards more sustainable and efficient transportation continues to drive innovative uses for aluminum.</p>

- Q: This question asks about the environmental effects caused by the extraction and processing of aluminum.

- <p>The environmental impacts of mining and processing aluminum are significant. Mining can lead to deforestation and habitat destruction, affecting biodiversity. The process of bauxite extraction releases large amounts of greenhouse gases, contributing to climate change. Additionally, the production of aluminum is energy-intensive, often relying on fossil fuels, which further exacerbates environmental issues. The release of toxic chemicals and heavy metals during processing can contaminate soil and water, posing risks to both ecosystems and human health. Moreover, the waste generated, such as red mud, can cause severe environmental damage if not properly managed. Overall, the aluminum industry has a substantial environmental footprint that requires sustainable practices to mitigate its effects.</p>

- Q: Is aluminum suitable for use in paint and coating applications?

- <p>Yes, aluminum can be used in paints and coatings. It is often used in the form of aluminum pigments or flakes, which provide a metallic appearance and enhance the durability and corrosion resistance of the coating. Aluminum pigments are also valued for their ability to reflect light and heat, making them useful in applications requiring thermal insulation or reflective properties. Additionally, aluminum can be used in powder coatings, providing a hard, wear-resistant finish.</p>

- Q: Is it possible to recycle aluminum from old products to create new ones?

- <p>Yes, aluminum can be recycled to make new products from old ones. Recycling aluminum is a highly efficient process that requires only 5% of the energy needed to produce new aluminum from raw materials. This process is not only environmentally friendly but also economically viable. Recycled aluminum maintains its quality and can be used to create a wide range of new products, from cans and packaging to automotive parts and construction materials.</p>

- Q: Is aluminum a suitable material for constructing aerospace structures?

- <p>Yes, aluminum is widely used in aerospace structures due to its high strength-to-weight ratio, corrosion resistance, and ease of fabrication. It is particularly favored for aircraft frames, wings, and fuselage components. Aluminum alloys are also used in spacecraft and satellite structures for their lightweight properties and ability to withstand extreme temperatures.</p>

- Q: Explain the relationship between aluminum and electrum, if any.

- <p>Aluminum and electrum are two distinct metals with no direct relationship. Aluminum is a lightweight, silvery-white metal that is the most abundant metallic element in the Earth's crust. It is known for its corrosion resistance and is widely used in various industries. Electrum, on the other hand, is a naturally occurring alloy of gold and silver, valued for its unique properties and historical significance. While both metals are used in various applications, they are chemically and physically different and do not have a direct connection.</p>

- Q: This question inquires about the potential differences in cooking performance when using various types of aluminum foil.

- <p>Yes, there are differences in cooking performance between different types of aluminum foil. The thickness of the foil can affect heat distribution and cooking time; heavier gauges are more durable and better for roasting and baking, while thinner foils are suitable for lining pans or wrapping foods. The quality of the foil, such as whether it's non-stick or not, can impact food release and cleanup. Additionally, some aluminum foils are designed to be heat resistant up to higher temperatures, making them suitable for broiling or grilling, while others may not withstand such high heat. It's important to use the appropriate type of aluminum foil for the specific cooking method to ensure food safety and optimal results.</p>

- Q: What are the various electronic components that utilize aluminum as a primary material?

- <p>Aluminum is used in several types of electronic components due to its good thermal conductivity, lightweight, and corrosion resistance. Some of the common components include: 1. Capacitors: Aluminum electrolytic capacitors are widely used for their high capacitance and low cost. 2. Heat sinks: Aluminum is a popular choice for heat sinks due to its ability to dissipate heat efficiently. 3. Semiconductors: Aluminum is used in semiconductor manufacturing, particularly for interconnects and as a barrier layer. 4. Conductive adhesives: Aluminum-filled adhesives are used for bonding components in electronics. 5. Wires and cables: Aluminum wire is used in some applications due to its lower weight compared to copper. 6. Reflectors: Aluminum is used in light reflectors for its reflective properties. 7. Housings and enclosures: Aluminum is used in the construction of electronic device casings for its strength and lightweight properties.</p>

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1995 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum AA5xxx Circles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0.5 T

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches